VS

07.94

1-110

Siemens AG 1997 All Rights reserved

SIMODRIVE 611A Installation and Start–Up Guide/IAA/–04.97 Edition

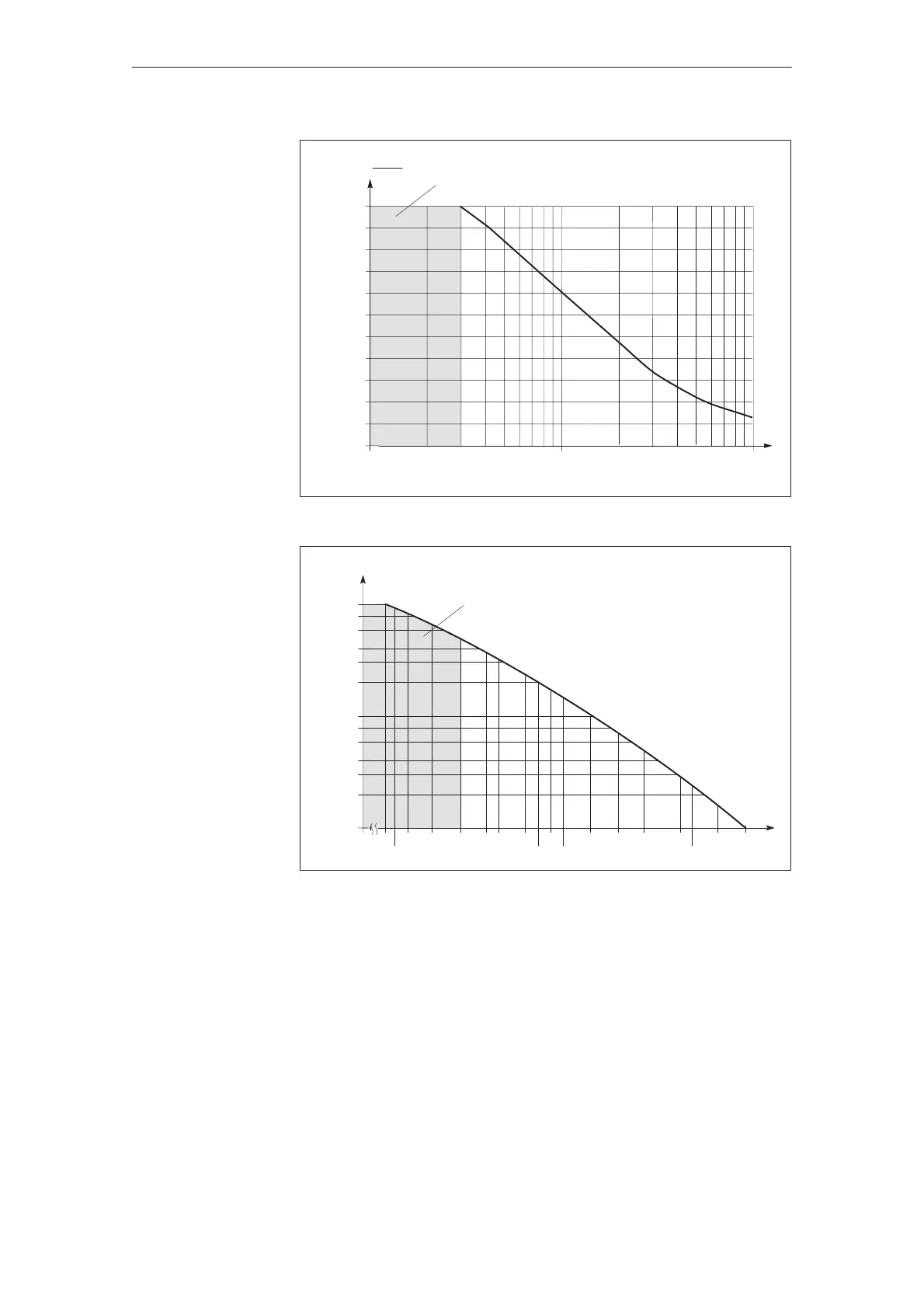

R9 [kΩ]

I

cont.

I

rated

100

90

80

70

60

50

40

30

20

10

10.0 100.0

0

110

1000.0

Illegal area

[%]

Fig. 3-6 Response threshold I

2

t monitoring as a function R9

1.0

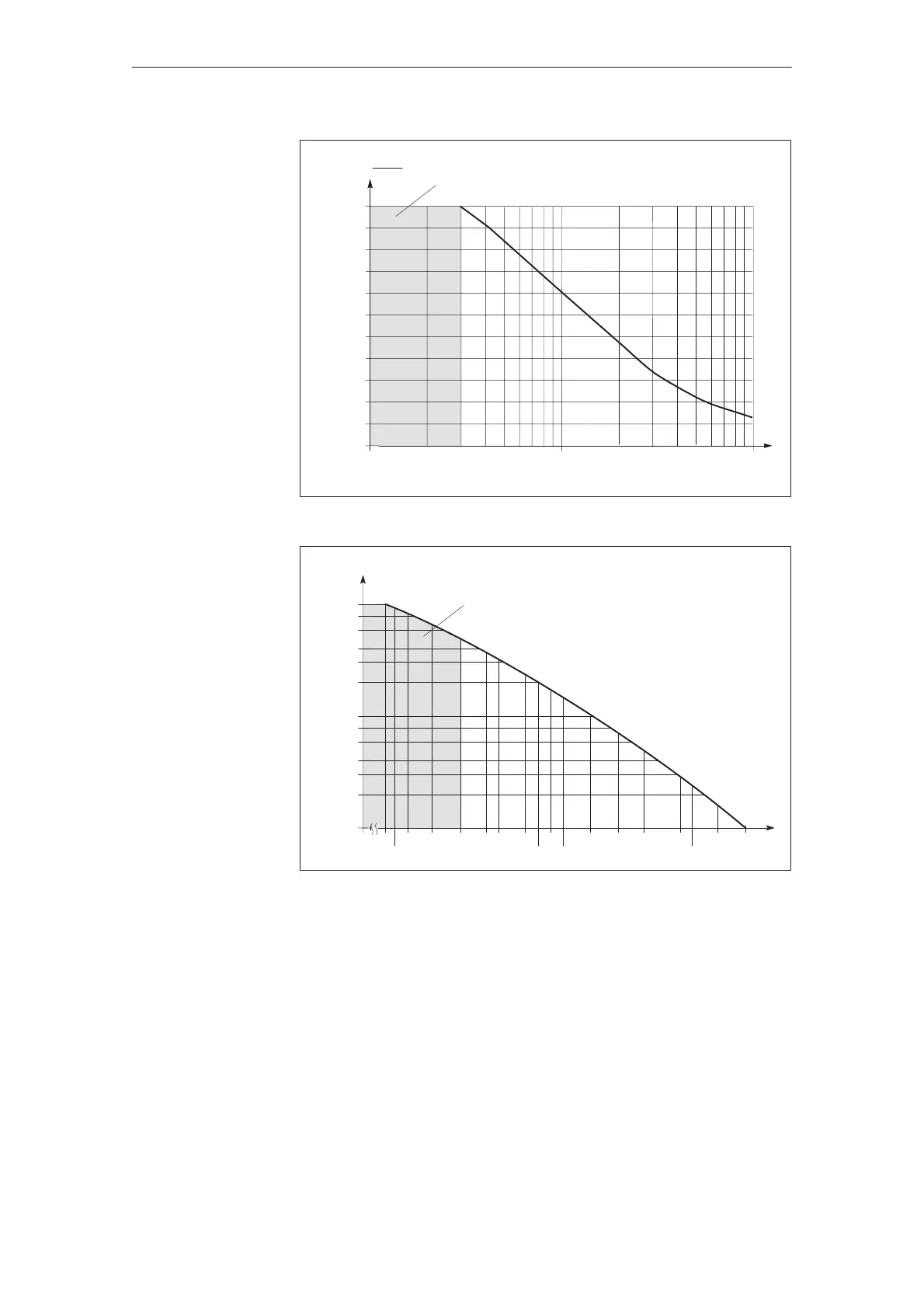

0.8

0.6

0.4

0.3

0.2

0.1

0.08

0.06

0.04

0.03

0.02

0.01

5

5.6

6.810 15222739

47

56

68

100

150220390

470

6801000

I

weight

compensation

/I

max

R46 and

R48 [k]

Illegal area

Fig. 3-7 Supplementary current setpoint for electronic weight equalization

Inverter clock frequency PWM

If noise problems occur (the motor makes a whistling sound), the PWM inverter

clock frequency can be adapted by mounting R369 on the basic board.

In this case, it must be observed that the available current (I

n

, I

max

) is redu-

ced when the clock frequency is increased. (refer to Pj Section 4.1)

The I2t limiting is designed for a pulse frequency set in the factory to 3.3 kHz

and a max. ambient temperature of 40

C. When this value is exceeded (pulse

frequency and/or ambient temperature), the response threshold must be adap-

ted (refer to Fig. 3-2).

The characteristic is valid according to Fig. 3-1.

J

Feed modules (VS)

04.973.2 Setting elements with user–friendly interface

Loading...

Loading...