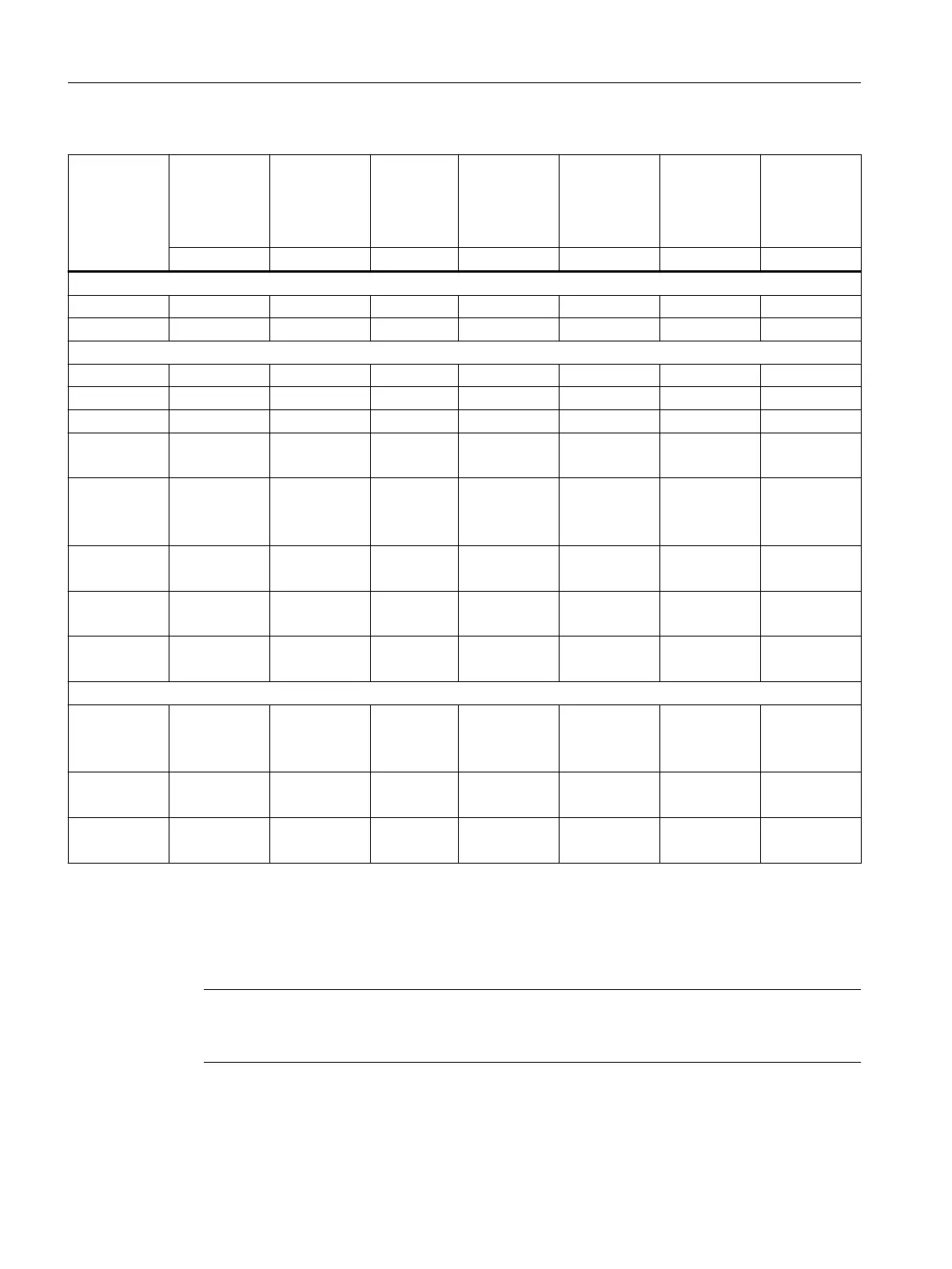

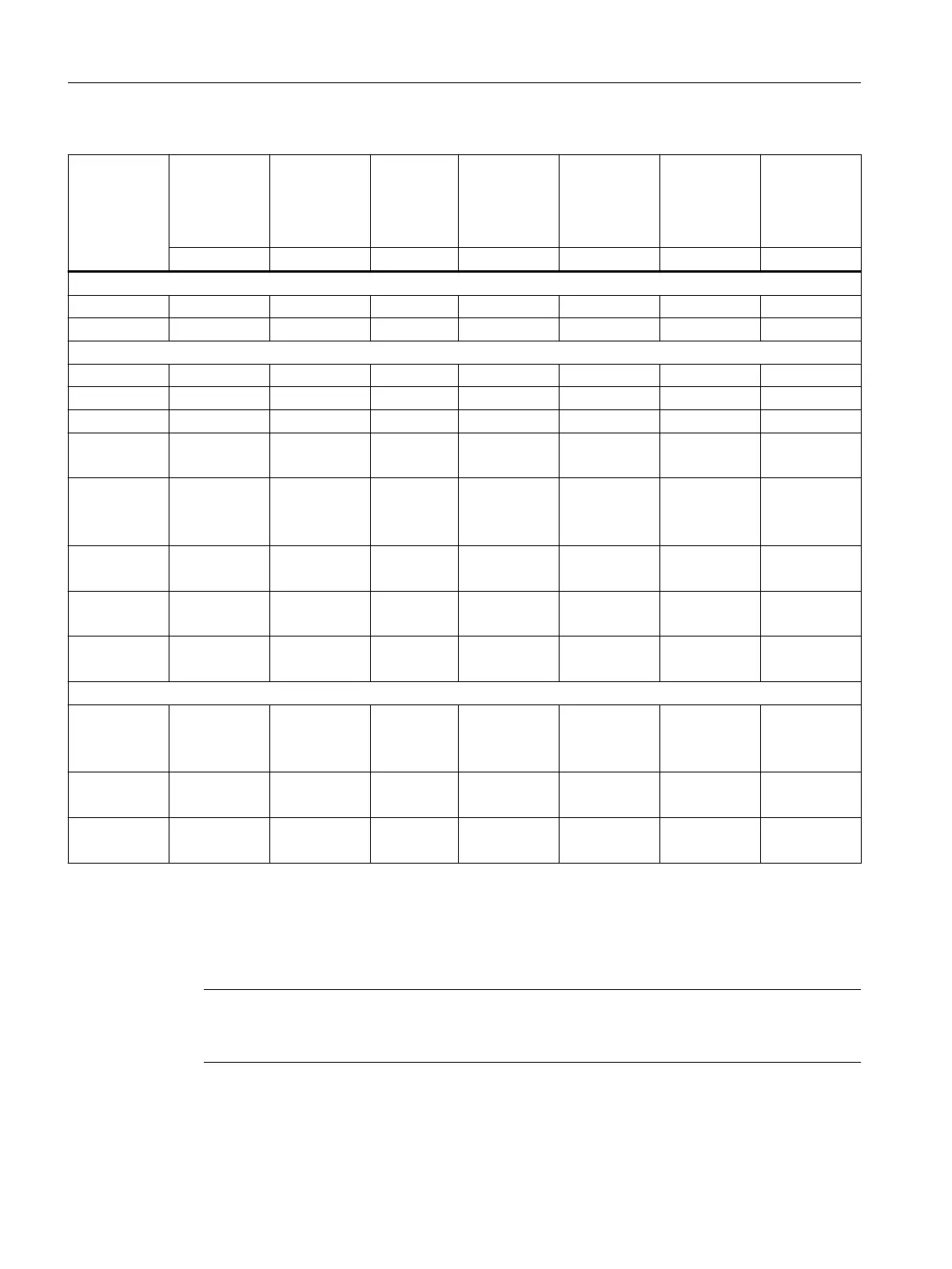

Motor type Holding tor‐

que at 120°C

Dyn. braking

torque

Rated cur‐

rent

Opening

time

1)

Closing

time

1)

Maximum

permissible

single oper‐

ating

energy

2)

Total operat‐

ing energy

(service life)

M

4

/ Nm M

1m

/ Nm I

supp

/ A t / ms t / ms W

max

/ J W

total

/ kJ

For spring-loaded brake

1F☐2☐03 1.3 1.3 0.4 90 30 62 5

1F☐2☐04 3.3 3.3 0.5 110 40 270 35

For permanent-magnet brake

1F☐2☐05 8 5 0.6 90 25 568 284

1F☐2106 16 9 0.7 100 50 1065 774

1F☐2206 13 6.5 0.7 100 50 1548 774

1FT2208-2

1F☐2☐08-3

19 12 0.8 100 40 2000 1800

1FT2108-4

1FT2108-5

1FT2108-7

36 12 0.9 200 60 1300 2400

1FK2☐08-4

1FK2☐08-5

32 17 0.9 200 60 4800 2400

1FT2210-2

1F☐2☐10-3

32 17 0.9 200 60 6658 2400

1F☐2☐10-4

1F☐2☐10-5

55 26 1.0 220 80 8700 3800

Higher rating brake for 1FT22☐☐-☐

1FT2108-4

1FT2108-5

1FT2108-7

32 17 0.9 200 60 4800 2400

1FT2208-2

1FT2208‑3

32 17 0.9 200 60 4800 2400

1FT2210-2

1FT2210‑3

55 26 1.0 220 80 8700 3800

1)

Measured with varistor for a rated holding brake voltage of 24VDC.

2)

Maximum three EMERGENCY STOP operations in sequence with a maximum of 25% total operating energy

Time-related terminology when operating a holding brake

Note

If the brake is switched in two stages (two clicks), the rst switching point is decisive for opening

and the second for closing.

Mounting and options

4.6Holding brake

SIMOTICS S-1FT2 synchronous motors for SINAMICS S120

52 Operating Instructions, 12/2023, A5E50610821B AF

Loading...

Loading...