4 Operating the Application

4.2 Operation via digital inputs

SINAMICS G120 DP at S7-1200

Entry-ID: 70155469, V1.4, 07/2018

Copyright Siemens AG 2018 All rights reserved

4.2 Operation via digital inputs

For security reasons, the SINAMICS drives in this application example are

exclusively moved via digital inputs, the HMI is only used for monitoring

.

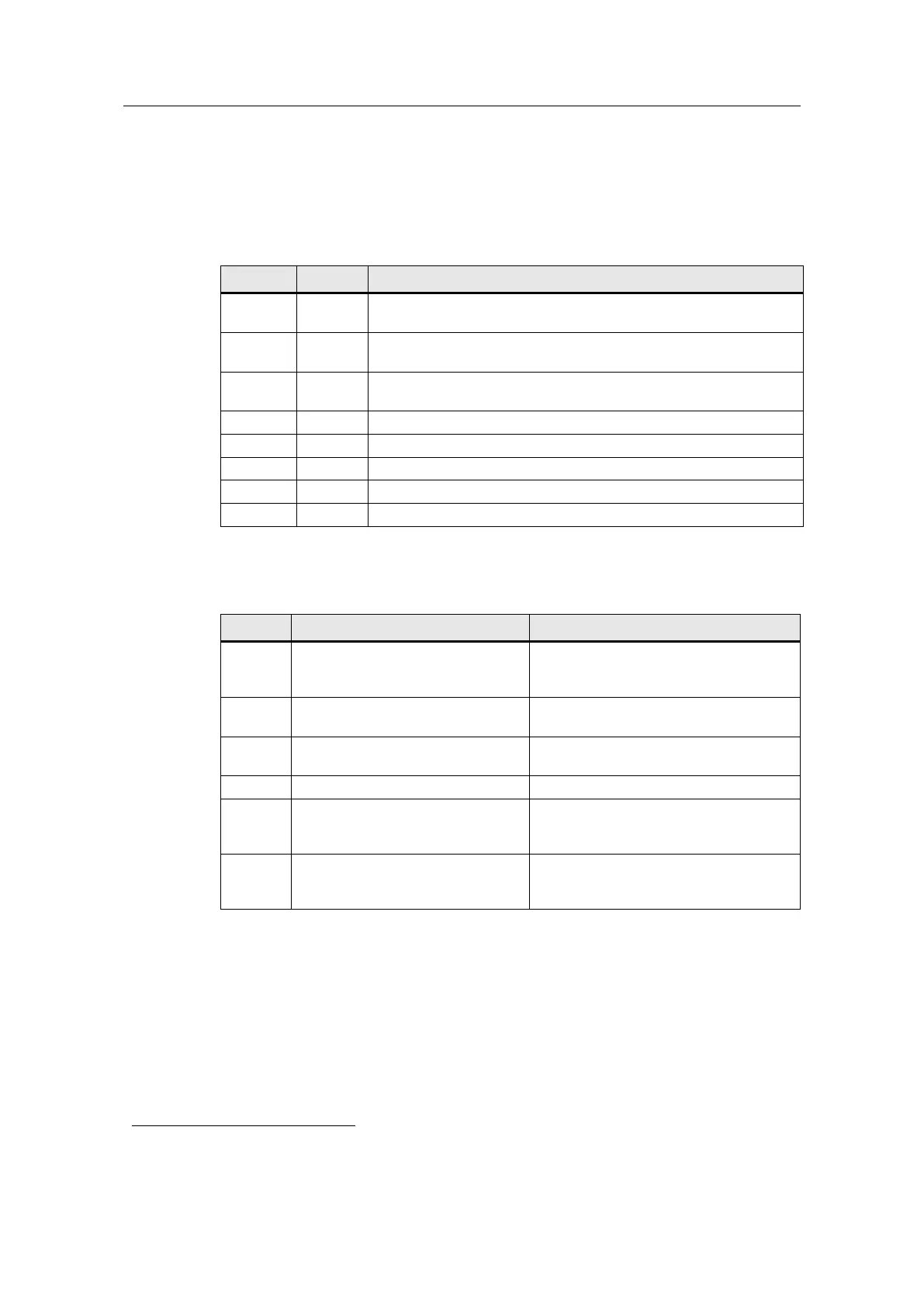

Table 4-1: Digital inputs

Switching the SINAMICS drive on/off,

(Off2 =1 and Off3 =1 must apply for the operation)

0 = Immediately switching off the motor. The SINAMICS drive

coasts.

0 = Fast stop. The motor is decelerated with ramp-down time Off3

(P1135) until it stops

A rising edge acknowledges a pending error in the SINAMICS drive

Reversed direction, the polarity of the setpoint value is negated.

The setpoint is set to 0.

The setpoint is increased

The setpoint is decreased

To switch on the SINAMICS drive, please perform the steps below:

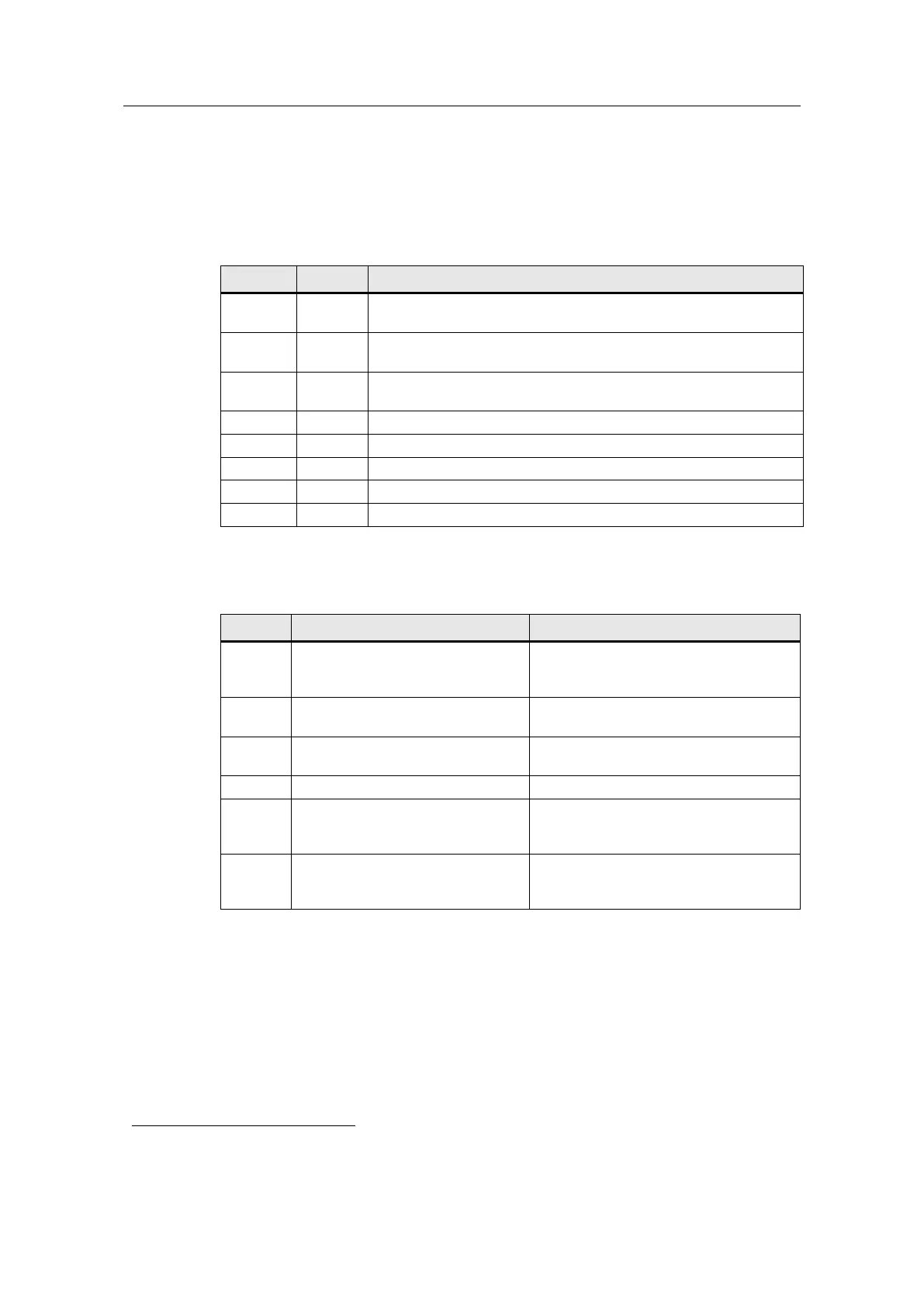

Table 4-2: Instruction – Switch on the SINAMICS drive

Apply 24V to “Off2” (I 0.1) and

“OFF3” (I 0.2).

The further required control bits for the

operation are permanently set to 1 by

the program.

Enter a pulse (switching on and

back off) to “Ack” (I 0.3).

This acknowledges a possibly pending

error message.

Enter a pulse (switching on and

back off) to “0” (I 0.5).

The setpoint is set to 0.

Apply 24V to “On” (I 0.0).

The SINAMICS drive switches on.

Change the setpoint value with

inputs “n+” (I 0.6), “n-” (I 0.7) and

“0” (I 0.5).

The speed of the motor changes.

Remove the 24V from “On” (I 0.0).

The SINAMICS drive switches back off

and the motor is shut down with the

configured ramp-down time.

If you still wish to control the drive from the HMI control device, you need to leave the input

parameters “control_word” and “setpoint” of the Process_Data [FB11] when calling it in

network 2 of the Main [OB1].

Loading...

Loading...