Troubleshooting and Fault Elimination

© Siemens AG, 2004. All rights reserved

8-50 EMC Installation Guideline – Planning Guide (EMV) – 03.2004 Edition

· Elimination of coupling paths to prevent interference sizes on reaching the

interference sink from the interference source (e. g. increase distance between

power and signal lines, inserting shielded lines, conduct lines to mass

proximity).

· Check the adherence of the measures requested in this EMC Guideline and

the product-specific documentation.

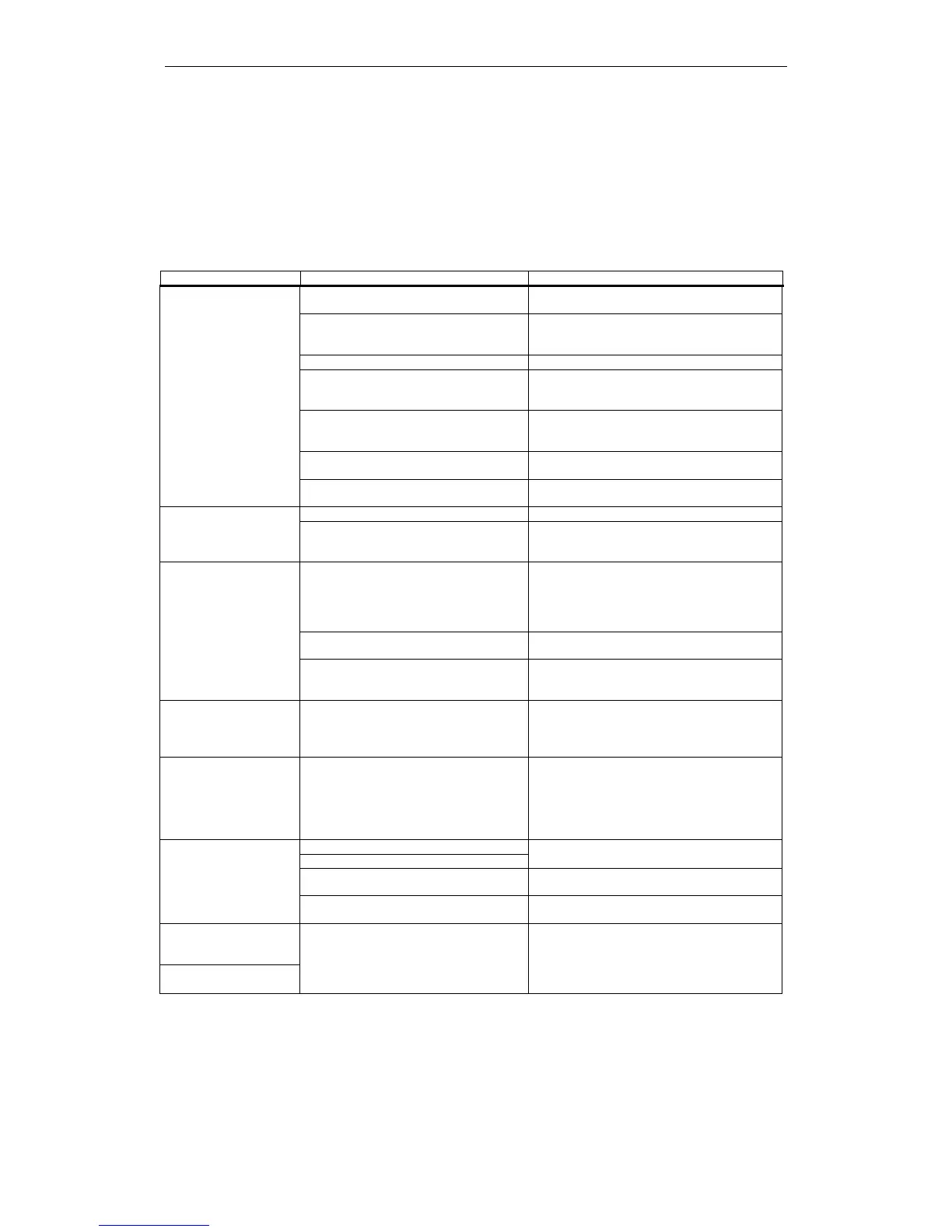

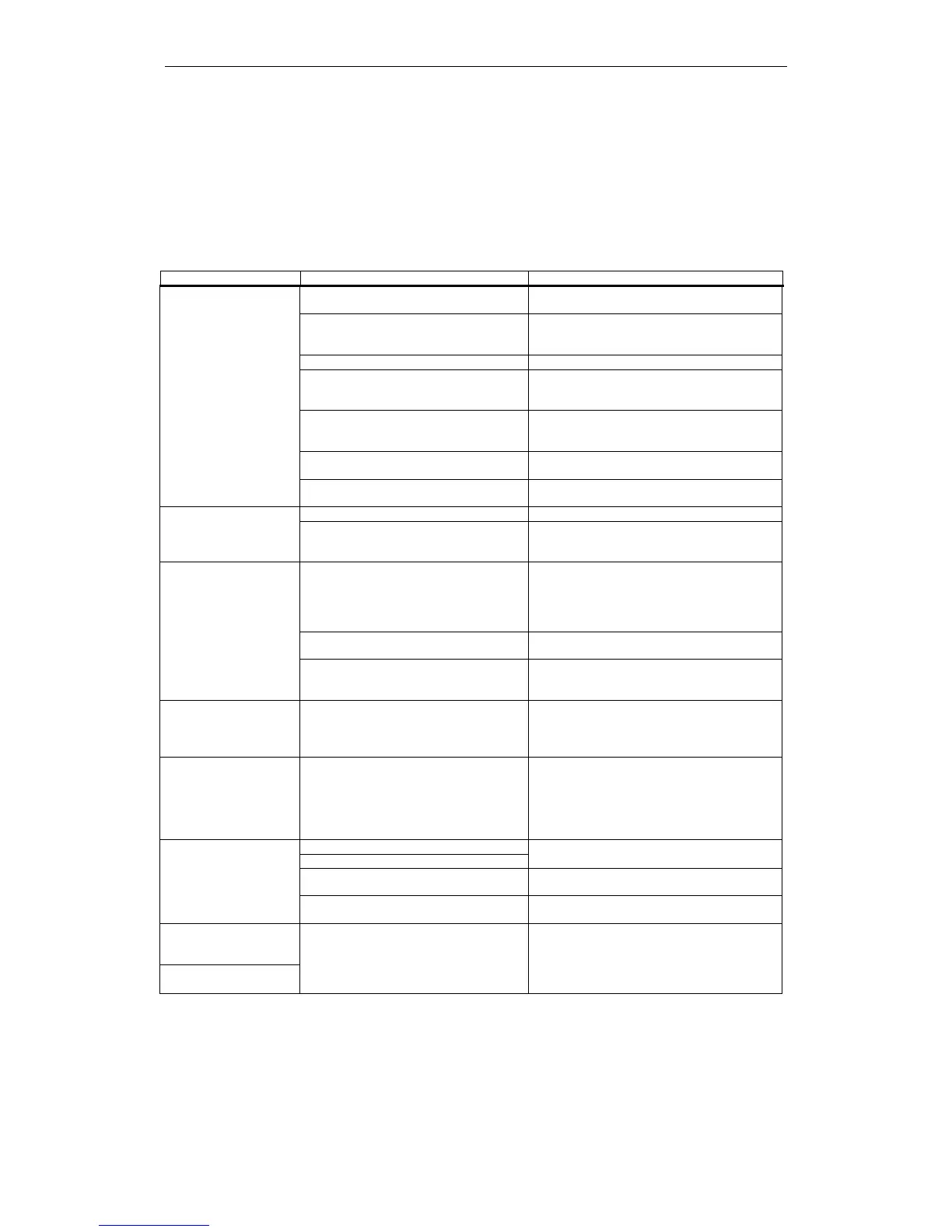

Table 8-1 Fault clearance

Misconduct Possible cause Fault elimination

Non-wired coils of contactors, valves,

horns, …

Wire the coils

Adjacent sparking machines (welding

equipment)

Route the lines of the control in another way

(increase the distance to the interference

source)

Transmitter, round control system Additional shielding

Lines with incorrect shield connection,

incorrect core twisting or incorrect

parameters

Use original lines, check the core occupancy

Interruption in the line shield

(e.g. with intermediate switching of a line

distributor)

Connection of the line shields, shielding of the

interruption point

Incorrectly routed equipotential bonding

line

Reroute equipotential bonding line

(see Chapter 4)

Sporadic failure

Contamination of the control Clean control and assemblies, provide for

clean supply air

Such as sporadic failure Such as sporadic failure Remaining offset

Actual value line Route equipotential bonding line between

transmitter housing and control housing or

improve equipotential bonding

Poor equipotential bonding connection

between position transmitter and control

· Provide for extensive, blank, corrosion-

resistant earth connection between

control and position transmitter

· Equipotential bonding line: Increase

cross-section, create direct connection

Large compensating current on setpoint

line shields (analog setpoint)

Interrupt shield connection on the control side

Irregular processing

surface

Foreign drive control: Setpoint input of the

drive control does not suit the Siemens

EMC concept

Change the input wiring of the drive control

(according to the wiring of the Siemens drive

controls)

Flickering screen

characters or screen

Adjacent magnetic field-producing device

(e.g. transformer, electric motor) or line

with current flowing through it

· Increase the distance between the screen

and the interference source

· In extreme cases, shield the screen or

interference source with MUMETALL

®

Extensive off-colours of

the screen display

Magnetic field of an adjacent permanent

solenoid

· Eliminate the interference source

· Shield the interference source with

MUMETALL

®

Note: Picture disturbance disappears without

demagnetization measures only some days

after the elimination of the cause

Transmitter line shield is interrupted

Lines with poor shield features

Insert original lines (product-specific)

Transmitter line shield put on via separate

wire/line

Insert shields on both sides

Transmitter error

Electrostatic charging/discharging of belts

or rotor

Use belts with antistatic coating, earth rotor via

earthing brush.

Telephones, fax

machines, copying

machines are whistling

Fuse case with small

power supply units

Short-circuit capacity of the mains is too

small

· Increase the short-circuit capacity of the

mains

· Supply the affected devices from another

mains

· Insert original filter module

n

Loading...

Loading...