Steering Gear Adjustment

If there is excessive slack in the steering system, the

steering gear backlash can be removed.

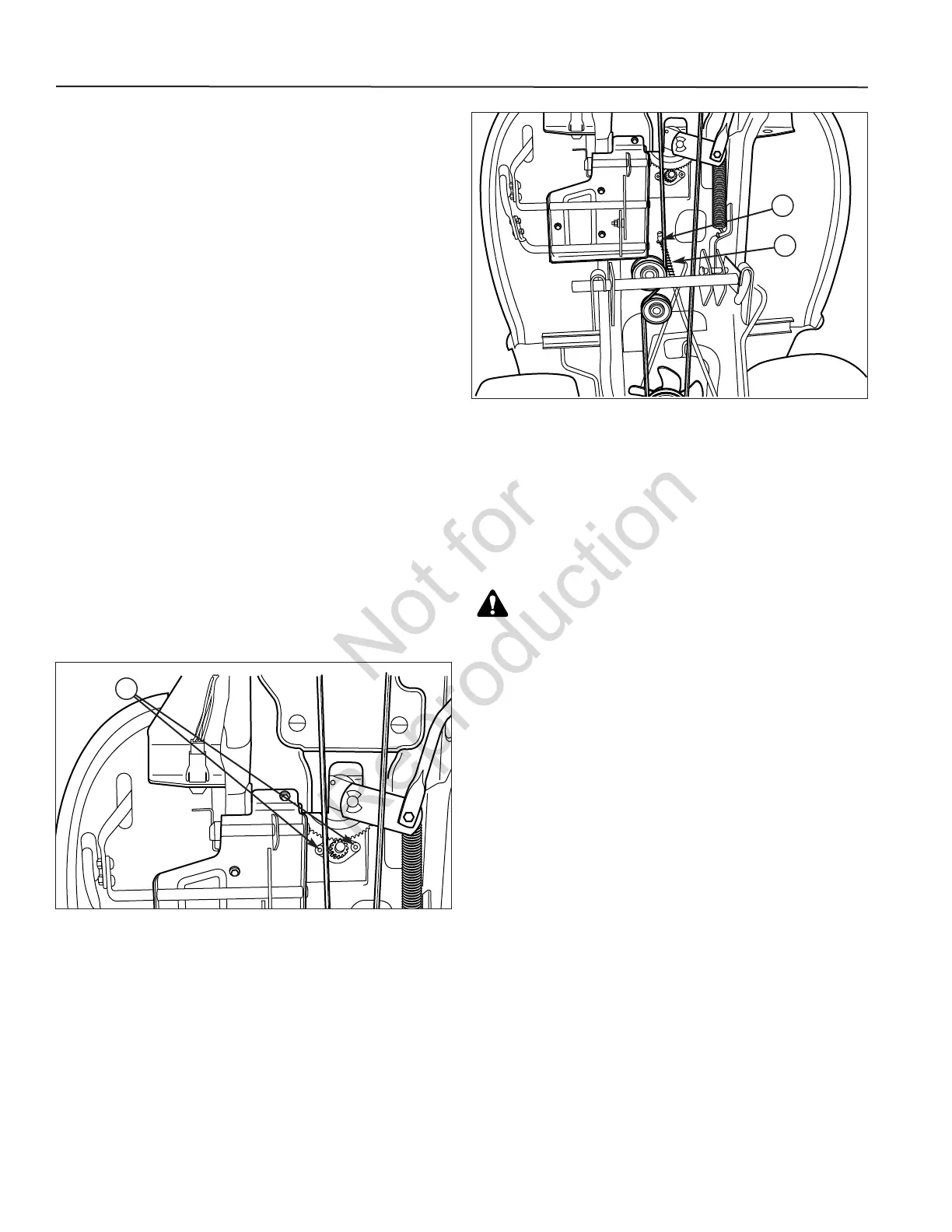

1. Locate the steering gear assembly on the underside

of the tractor (see Figure 22). Loosen the two nuts

and adjust the bracket so the gear teeth are closely

meshed.

2. Tighten nuts (A) to 36-44 ft-lbs (49-59 Nm) after

adjustment.

Brake Adjustment

1. Disengage the PTO, stop the engine, block the

wheels, remove the ignition key, and engage the

parking brake.

2. Remove the mower deck (see Mower Deck

Removal).

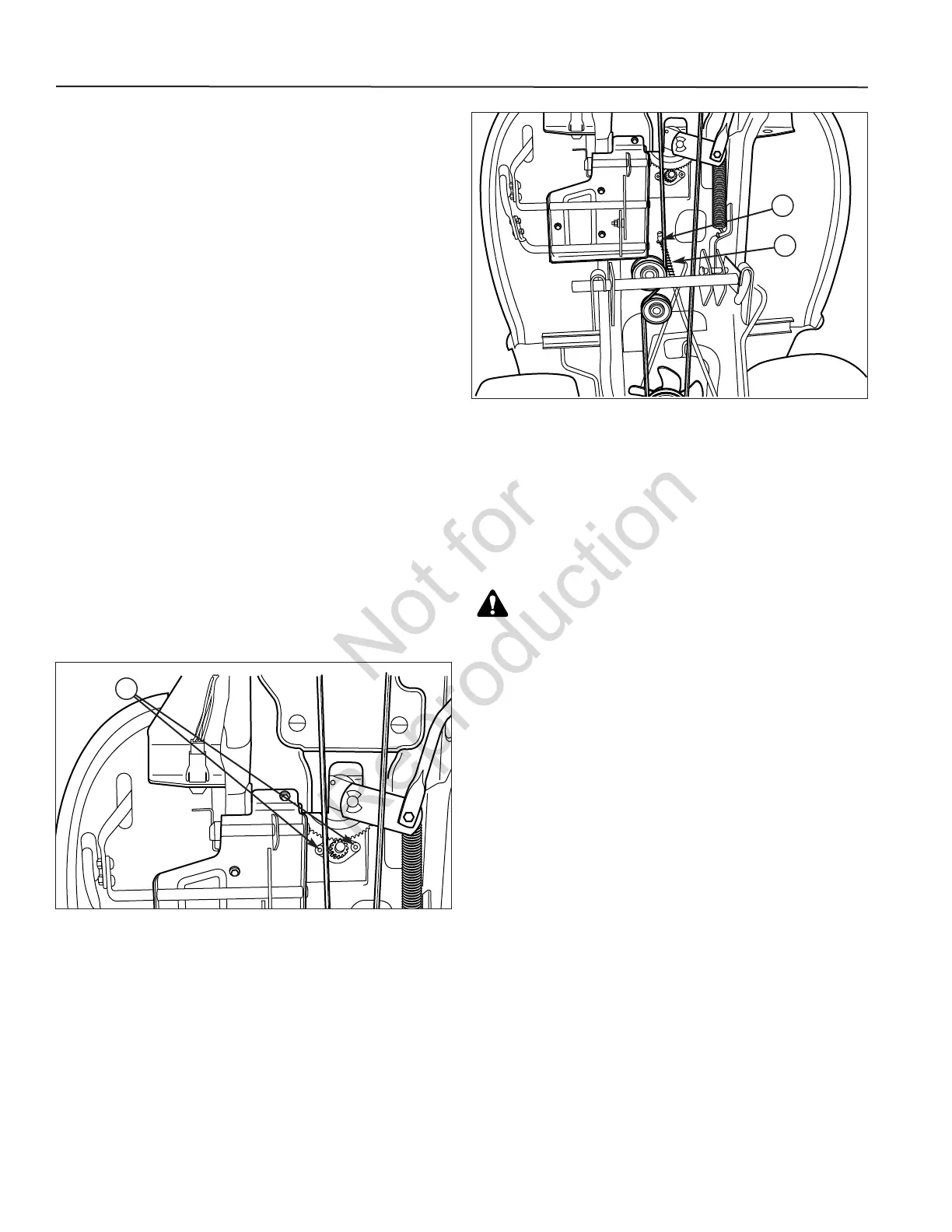

3. Locate the brake spring (A, Figure 23) and

adjustment nut (B).

4. With the parking brake engaged, measure the

compressed spring length. The spring should be 2-

1/2” (6,4 cm) when compressed.

If the spring is not within this range, turn the

adjustment nut to compress or release the spring.

If this adjustment does not correct a braking problem,

see your dealer.

Figure 22. Steering Gear Adjustment (Manual

Steering Only)

Figure 23. Brake Spring Adjustment

A

B

A

WARNING

To avoid serious injury, perform adjustments only

with engine stopped, key removed and tractor on

level ground.

30

TROUBLESHOOTING

PTO Clutch Adjustment

Check the PTO clutch adjustment after every 250 hours

of operation. Also perform the following procedure if the

clutch is slipping or will not engage, or if a new clutch

has been installed.

1. Remove key from ignition switch and disconnect

spark plug wires to prevent the possibility of

accidental starting while the PTO is being adjusted.

2. Note the position of the three adjustment windows (A,

Figure 24) in the side of the brake plate and the

nylock adjustment nuts (B).

3. Insert a .012”-.015” (2,5-4 mm) feeler gauge (A,

Figure 25) through each window, positioning the

gauge between the rotor face and the armature face

(B) as shown.

4. Alternately tighten the adjustment nuts (C) until the

rotor face and armature face just contacts the gauge.

Loading...

Loading...