11 - 13

11 Transmission Teardown

Hydro-Gear 0500 / 0650

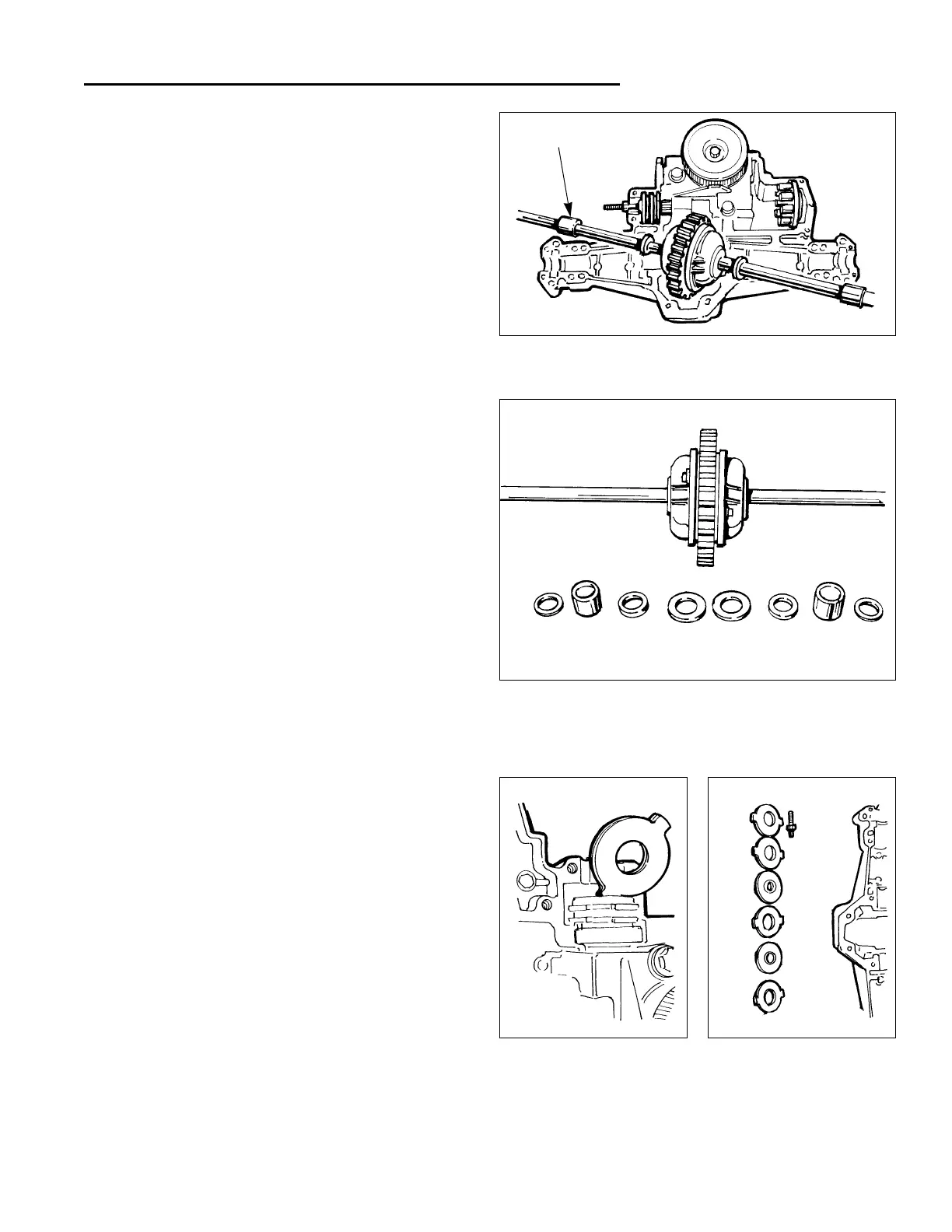

Figure 9. Remove Axle / Differential Assembly

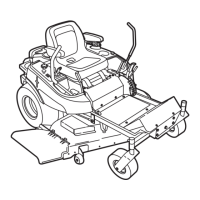

10.Inspect the bronze bearings for excessive wear. The

bearings should be 0.754” to 0.756”.

11.Inspect the axle ends for damage or excessive wear.

The axle ends should be 0.749” to 0.750”.

Figure 10. Axle / Differential Components

12.Inspect the differential bevel gears by rotating the

axle ends.

13.Inspect the final drive gear teeth for excessive wear

or damage.

14.Check the differential assembly screws for proper

torque. They should be torqued to 16-18 ft. lbs.

15.Inspect the journal bearings inside the differential

housing for excessive wear by feeling the shafts for

an unreasonable amount of play.

16.If excessive wear or damage has been found, the

complete assembly must be replaced.

Journal Bushing

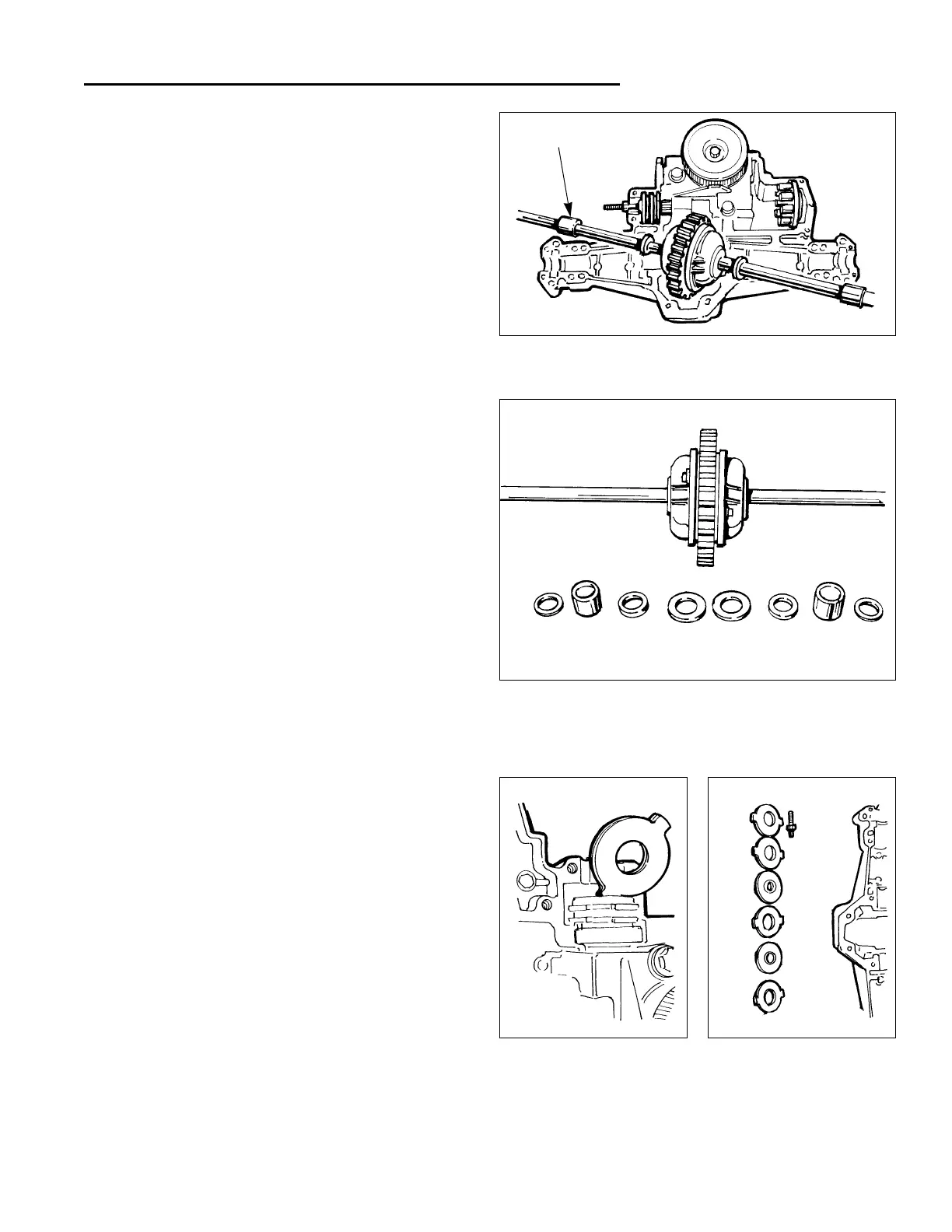

Figure 11. Remove / Inspect Brake Rotors

17.Remove the brake rotors and stators by sliding one at

a time off the end of the splined motor shaft.

18.Inspect each side of both rotors for excessive wear or

damage.

19.Inspect the rotor’s internal splines for excessive wear

or damage.

20.Replace rotors and stators as a complete kit if exces-

sive wear or damage is found. Inspect all other mating

parts.

Loading...

Loading...