6 - 5

6 Common Service Procedures

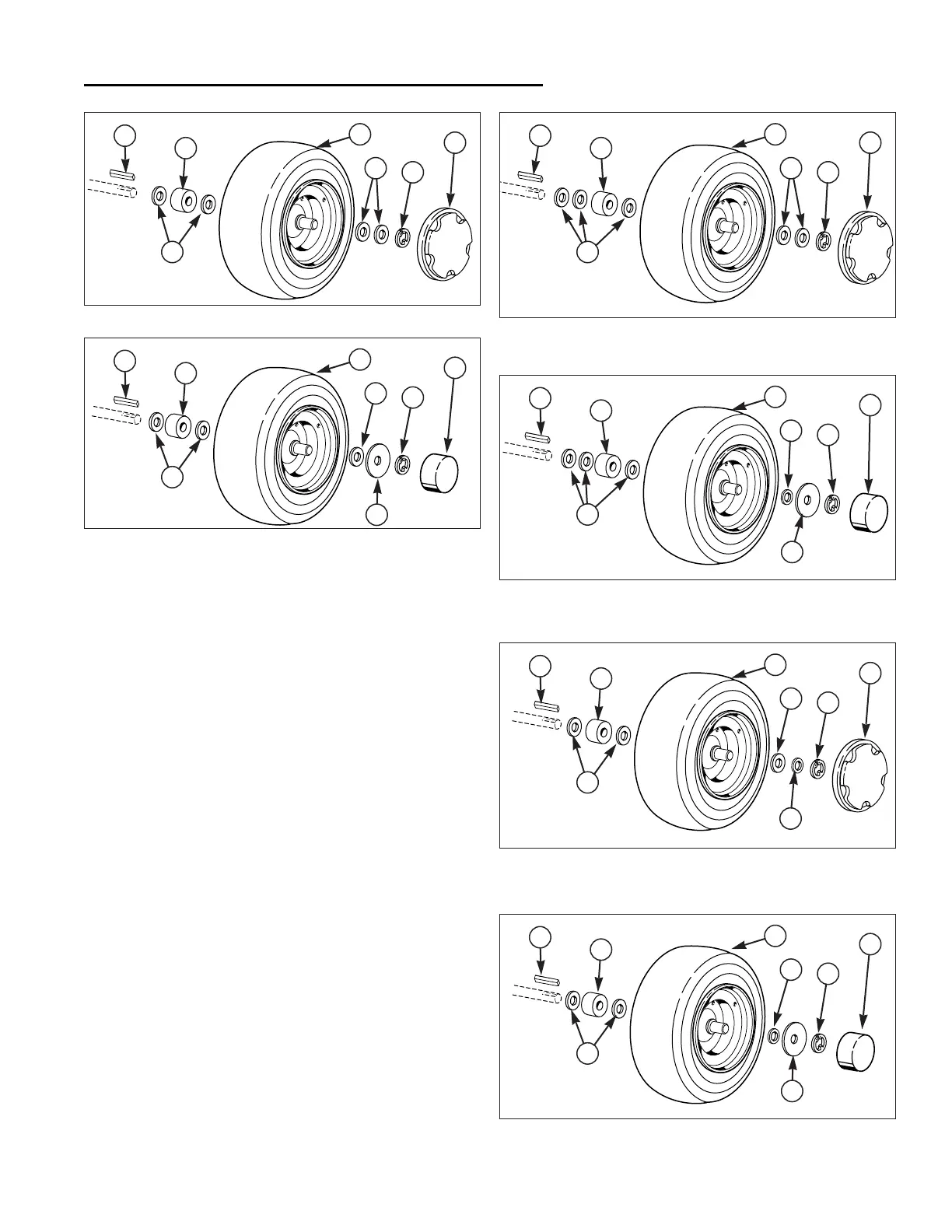

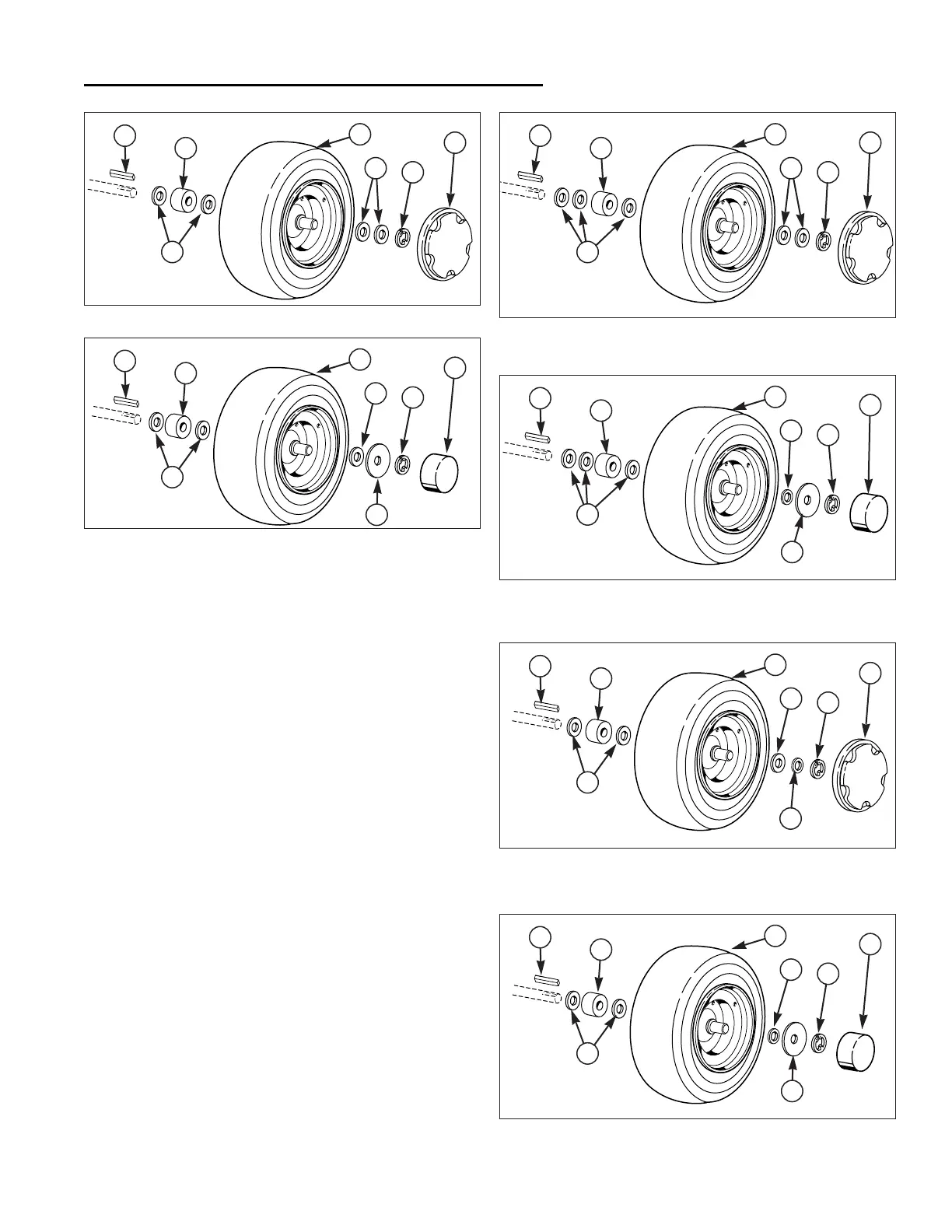

Rear Wheel Installation & Removal

REAR WHEEL INSTALLATION

AND REMOVAL

Refer to Figures 9-14.

1. Remove the key and disconnect the spark plug wire

while working on the unit.

2. Elevate the rear of the unit. See ELEVATING REAR

END FOR SAFE SERVICE.

3. Remove the plastic hub cap (H).

4. Remove e-ring (G) using a screwdriver.

5. Remove the washers (B & E), spacers (C), wheel (D),

and key (A).

NOTE: Your axle assembly may differ slightly from

the assembly pictured: washers may be missing or

doubled. This is adjusted on a tractor by tractor

basis during assembly to allow a small amount of

axle end-play.

6. Lubricate the axle shaft with anti-seize compound or

lithium grease.

7. Reinstall components in reverse order of disassembly

and lower the unit. Be sure the key (A) is in place in

the axle keyway.

A. Key E. Small Washer

B. Large Washer F. Hub Cap Retainer

C. Spacer G. E-Ring

D. Wheel H. Hub Cap

Figure 9. Regent, Tuff Torq K56 Models

A

C

D

H

G

B

B

Figure 11. Regent, Hydro-Gear 0500/0650 Models

A

C

D

H

G

B

Figure 10. 500/2500, Tuff Torq K56 Models

A

F

C

D

H

G

B

B

Figure 12. 500/2500, Hydro-Gear 0500/0650 Models

A

F

C

D

H

G

E

B

B

Figure 13. Regent, Peerless (Gear) Models

A

C

E

D

H

G

B

B

Figure 14. 500/2500, Peerless (Gear) Models

A

F

C

D

H

G

B

E

Loading...

Loading...