INSTALLATION

OF

THE

MACHINE

(Figure 1)

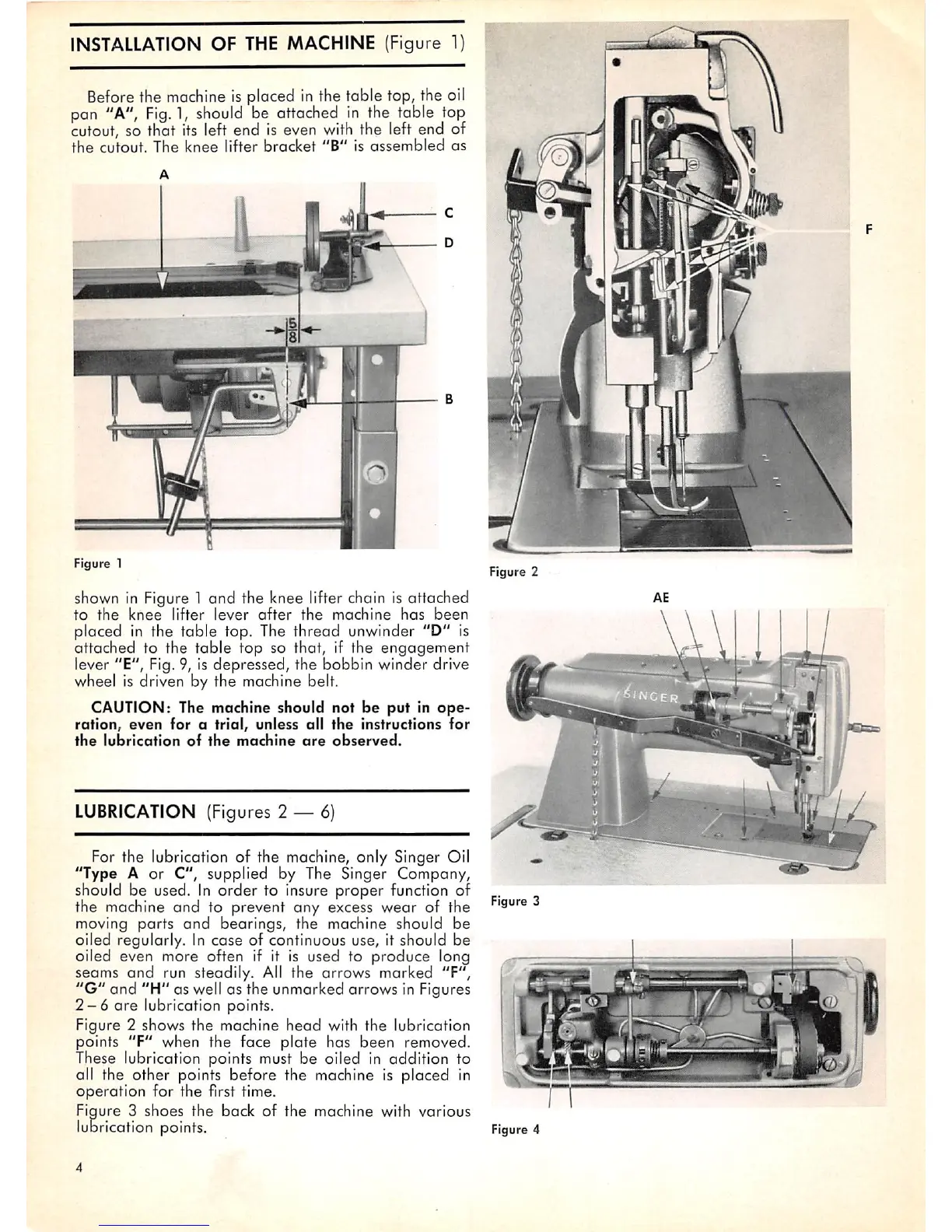

Before the machine is placed in the table top, the oil

pan "A",

Fig.

1,

should

be attached

in

the table top

cutout, so that its left end is even with the left end of

the

cutout.

The

knee

lifter

bracket

"B"

is

assembled

as

•mH

Figure 1

shown in Figure 1 and the knee lifter chain is attached

to

the

knee

lifter

lever

after

the

machine

has

been

placed in the table top. The thread unwinder "D" is

attached

to the

table

top

so that, if the

engagement

lever "E", Fig.9, is depressed, the bobbin winder drive

wheel is driven by the machine belt.

CAUTION: The machine should not

be

put

in

ope

ration,

even

for

a

trial,

unless

all

the

instructions

for

the

lubrication

of

the

machine

are

observed.

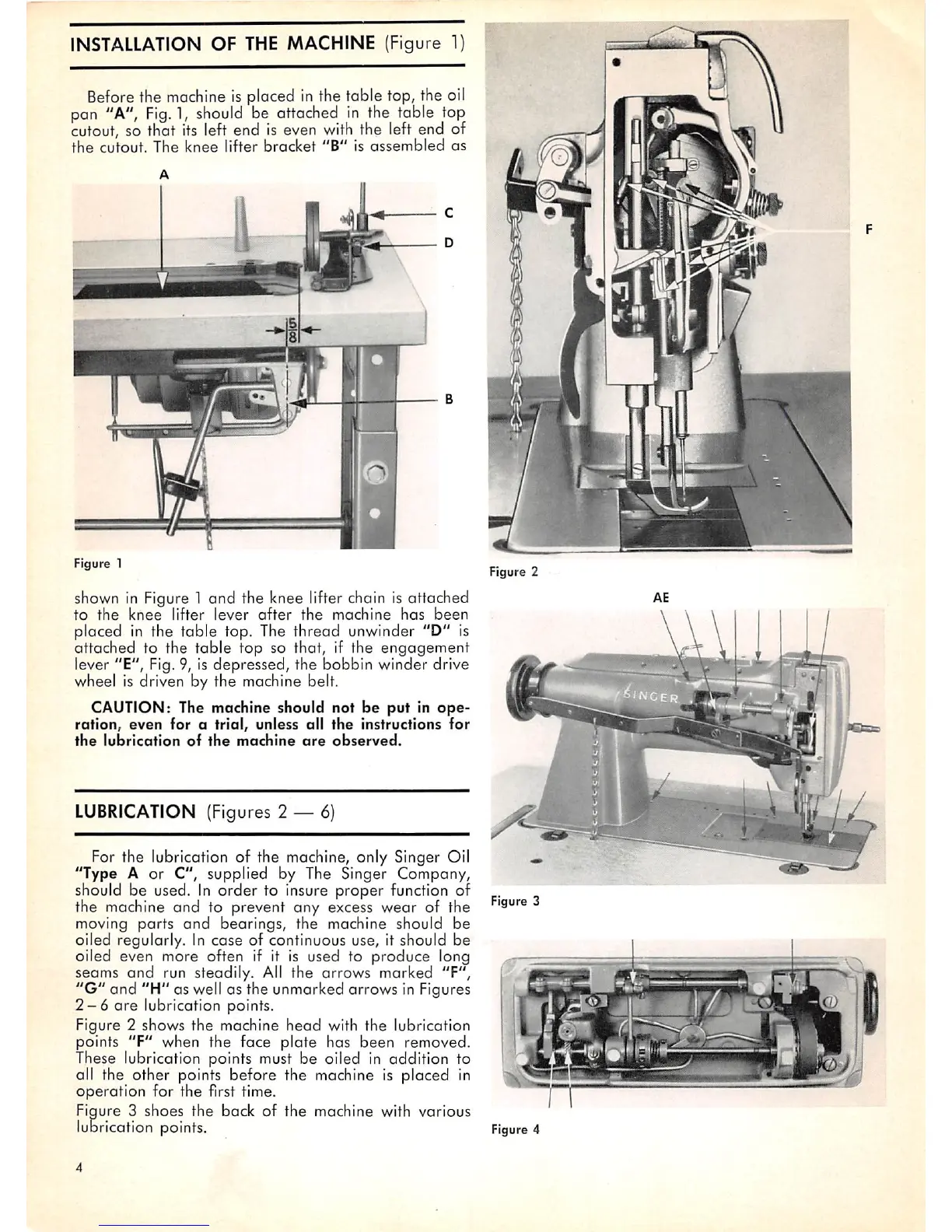

LUBRICATION (Figures 2 — 6)

For the lubrication of the machine, only Singer Oil

"Type A or C", supplied by The Singer Company,

should be used. In

order

to insure proper function of

the machine

and

to prevent any excess wear of the

moving

parts

and

bearings, the machine should be

oiled regularly. In

case

of continuous use, it should be

oiled even more often if it is used to

produce

long

seams

and

run steadily. All the

arrows

marked "F",

"G"

and

"H"

as well as the unmarked

arrows

in Figures

2-6

are

lubrication points.

Figure 2 shows the machine

head

with the lubrication

points

"F"

when the face

plate

has

been

removed.

These lubrication points must be oiled in addition to

all the other points before the machine is placed in

operation

for

the

first time.

Figure 3 shoes the back of the machine with various

lubrication points.

1

Figure 2

Figure 3

Figure 4

Loading...

Loading...