Figure 4 shows the underside of the 211

G155

MACHINE

and

Fig. 5 that of the

211

0156

MACHINE

with the lubrication points for both machines.

They

can

be oiled

when

the

machine

is

tilted

bock

on

its

hinges.

Figure 5

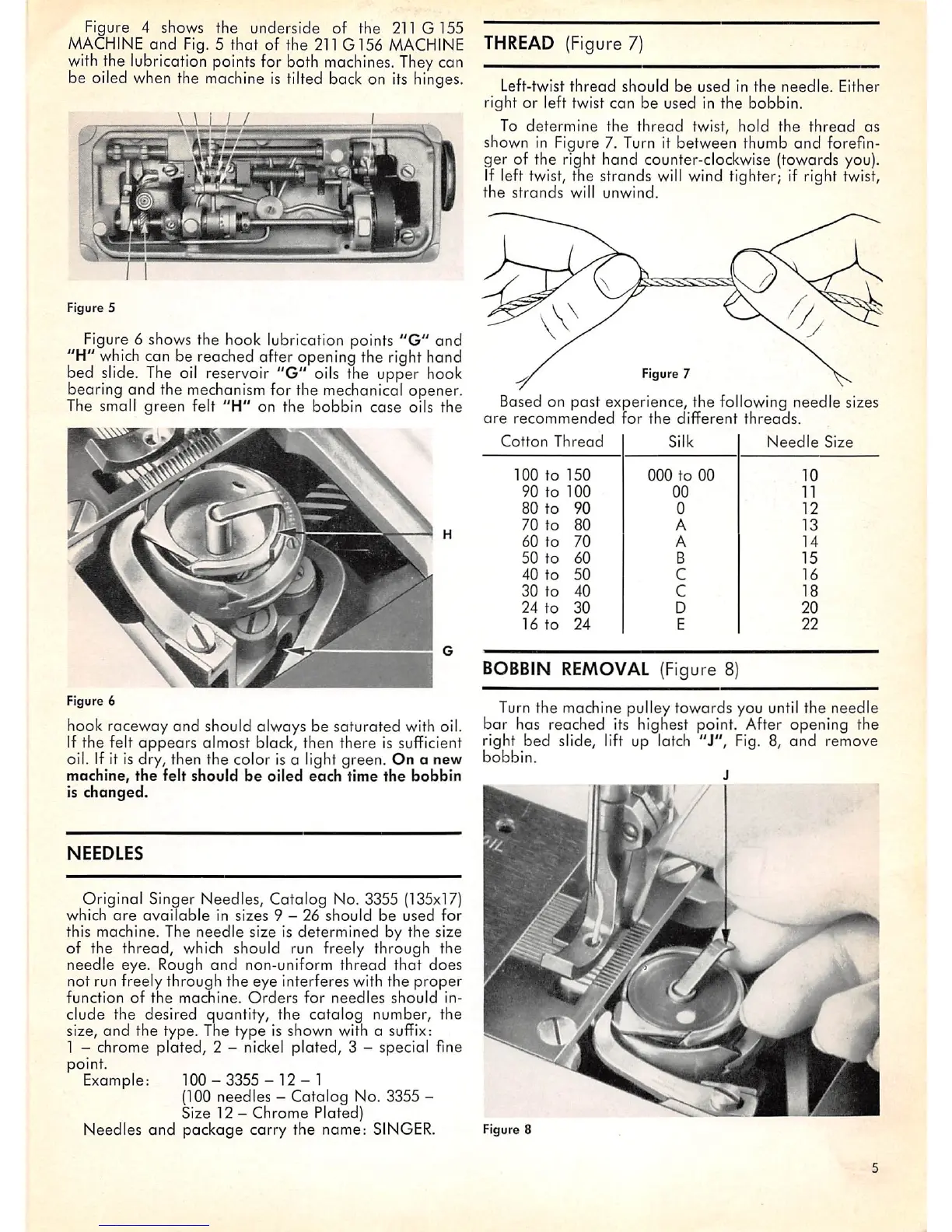

Figure 6 shows the hook lubrication points

"G"

and

"H"

which

can be reached after opening the right hand

bed slide. The oil reservoir "G" oils the upper hook

bearing and the mechanism for the mechanical opener.

The small

green

felt

"H"

on the bobbin

case

oils the

Figure 6

hook raceway and should always be saturated with oil.

If the felt

appears

almost black, then

there

is sufficient

oil. If it is dry, then the color is a light green. On a new

machine,

the

felt

should

be

oiled

each

time

the

bobbin

is

changed.

NEEDLES

Original Singer Needles, Catalog No. 3355

(135x17)

which

are

available

in

sizes

9-26

should

be

used

for

this machine. The needle size is determined by the size

of the

thread,

which should run freely through the

needle eye. Rough

and

non-uniform

thread

that

does

not run freely through the eye interferes with the proper

function

of

the

machine.

Orders

for

needles

should

in

clude the desired auantity, the

catalog

number, the

size,

and

the type. Tne type is shown with a suffix:

1 - chrome plated, 2 - nickel plated, 3 - special fine

point.

Example: 100

-3355

- 12

-1

(100 needles - Catalog No. 3355 -

Size 12 - Chrome Plated)

Needles

and

package carry the name: SINGER.

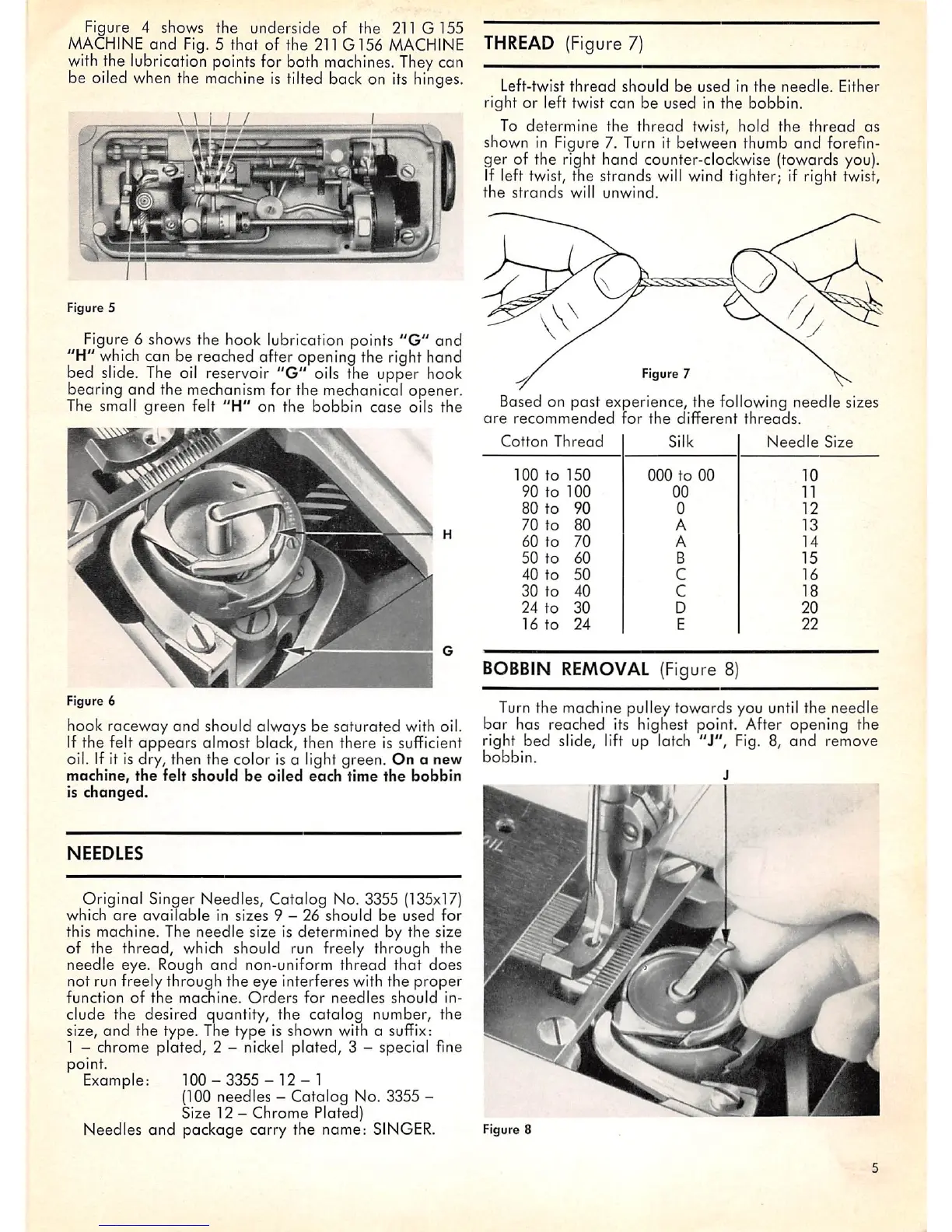

THREAD

(Figure 7)

Left-twist

thread

should

be

used

in

the

needle.

Either

right or left twist can be used in the bobbin.

To

determine

the

thread

twist, hold

the

thread

as

shown in Figure 7. Turn it between thumb

and

forefin

ger

of the right hand counter-clockwise (towards you).

If left twist, the strands

will

wind tighter; if right twist,

the

strands

will

unwind.

Based on past experience, the following needle sizes

are

recommended

for

the

different

threads.

Cotton

Thread

Silk

Needle

Size

100

to

150

000

to

00

10

90

to

100

00

n

80

to

90

0

12

70

to

80

A

13

60

to

70

A

14

50

to

60

B

15

40

to

50

C

16

30

to

40

C

18

24

to

30

D

20

16

to

24

E

22

BOBBIN

REMOVAL

(Figure 8)

Turn the machine pulley towards you until the needle

bar

has reached its highest point. After opening the

right bed slide, lift up latch

"J",

Fig. 8,

and

remove

bobbin.

J

Figure 8

Loading...

Loading...