REGULATION

OF

PRESSER

FOOT

PRESSURE

(Figure 3)

The

pressure on the material should be as light as

possible while

still

sufficient to insure correct feeding.

The presser foot pressure is adjusted with screw

"AE", Fig. 3. Turning of the screw clockwise increases

and

counter-clockwise

decreases

the pressure.

REENGAGEMENT

OF

SAFETY

CLUTCH

(Figure 13)

A safety clutch to prevent any overload

and

damage

to the hook is installed in the lower belt pulley. If it is

disengaged, open the bed slide

and

check the hook.

Remove all thread

and

foreign matter from the hook

by carefully turning the machine pulley forward and

backward until the machine turns freely. Bypressing the

stitch

length

regulator

button

"AD",

Fig.

13,

and at the

same time turning the machine pulley,the hook driving

shaft is locked

until

the safety clutch isreengaged. Reset

the

stitch

length

and the

machine

is ready for

sewing.

TO

USE THE REVERSE FEED

ON

THE

2110156

MACHINE

(Figures

20 and

26)

The feed of the machine can be reversed by hand

lever

or

foot

treadle.

To change feed direction by hand, push the reverse

lever "AF",

Fig.

20, completely down in order to have

the same stitch length as in forward feed.

Release it only when you want to again feed the

material

in

the

normal

direction.

To reverse the

feed

with the foot

treadle,

the

foot

treadle

chain

should

be

connected

to

the

hole

in

the

reversing lever "AG", Fig. 26.

TIMING

AND

OTHER

ADJUSTMENTS

The instructions on the following pages are for Adjusters and Mechanics only.

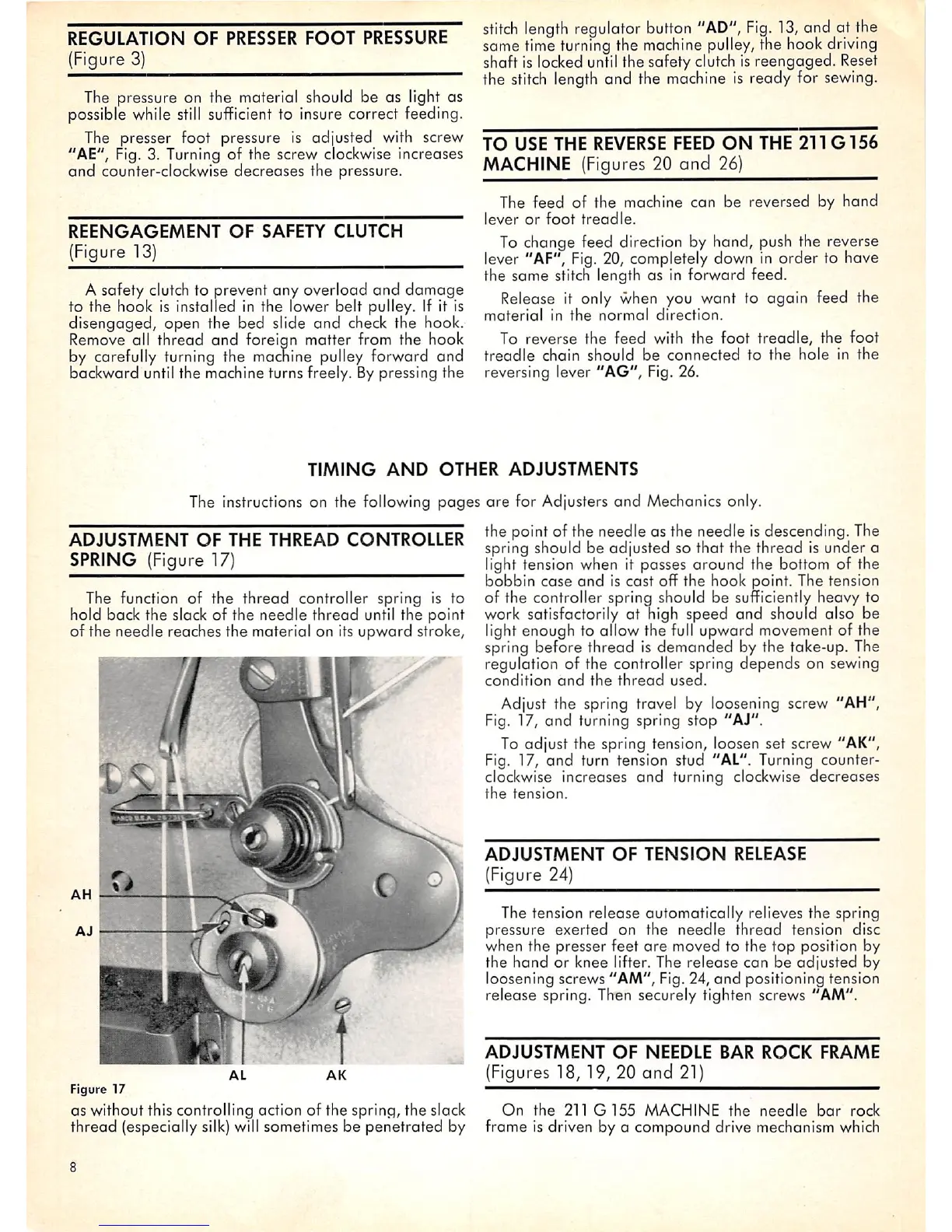

ADJUSTMENT

OF

THE

THREAD

CONTROLLER

SPRING (Figure 17)

The function of the

thread

controller spring is to

hold back the slack of the

needle

thread

until the point

of the needle reaches the material on its upward stroke.

AL

AK

Figure 17

as without this controlling action of the spring, the slack

thread

(especially silk) will sometimes be

penetrated

by

the point of the needle as the needle is descending. The

spring should be adjusted so that the thread

Is

under a

light tension when It passes around the bottom of the

bobbin

case

and

is

cast

off the hook point. The tension

of the controller spring should be sufficiently heavy to

work satisfactorily at high speed and should also be

light enough to allow the full upward movement of the

spring before thread is demanded by the take-up. The

regulation of the controller spring depends on sewing

condition

and

the

thread

used.

Adjust the spring travel by loosening screw "AH",

Fig. 17,

and

turning spring stop "AJ".

To adjust the spring tension, loosen set screw "AK",

Fig. 17,

and

turn tension stud "AL". Turning counter

clockwise increases

and

turning clockwise

decreases

the

tension.

ADJUSTMENT

OF

TENSION

RELEASE

(Figure 24)

The tension release automatically relieves the spring

pressure exerted on the

needle

thread

tension disc

when the presser feet

are

moved to the

top

position by

the

hand

or knee lifter. The release can be adjusted by

loosening screws "AM", Fig. 24,

and

positioning tension

release spring. Then securely tighten screws "AM".

ADJUSTMENT

OF

NEEDLE

BAR

ROCK

FRAME

(Figures 18, 19, 20 and

21)

On

the

211

G155

MACHINE

the

needle

bar

rock

frame is driven by a compound drive mechanism which

Loading...

Loading...