can be made synchronous or differentiated with the

lowerfeed. It

must

be adjusted so that, in zero position

of the synchronous feed, the distance between the

vibrating presser

bar

in the needle

bar

rock frame

and

the vertically moving presser bar, in the arm, is

2V64

inch

= 8,33 mm {see Figure

21}.

h

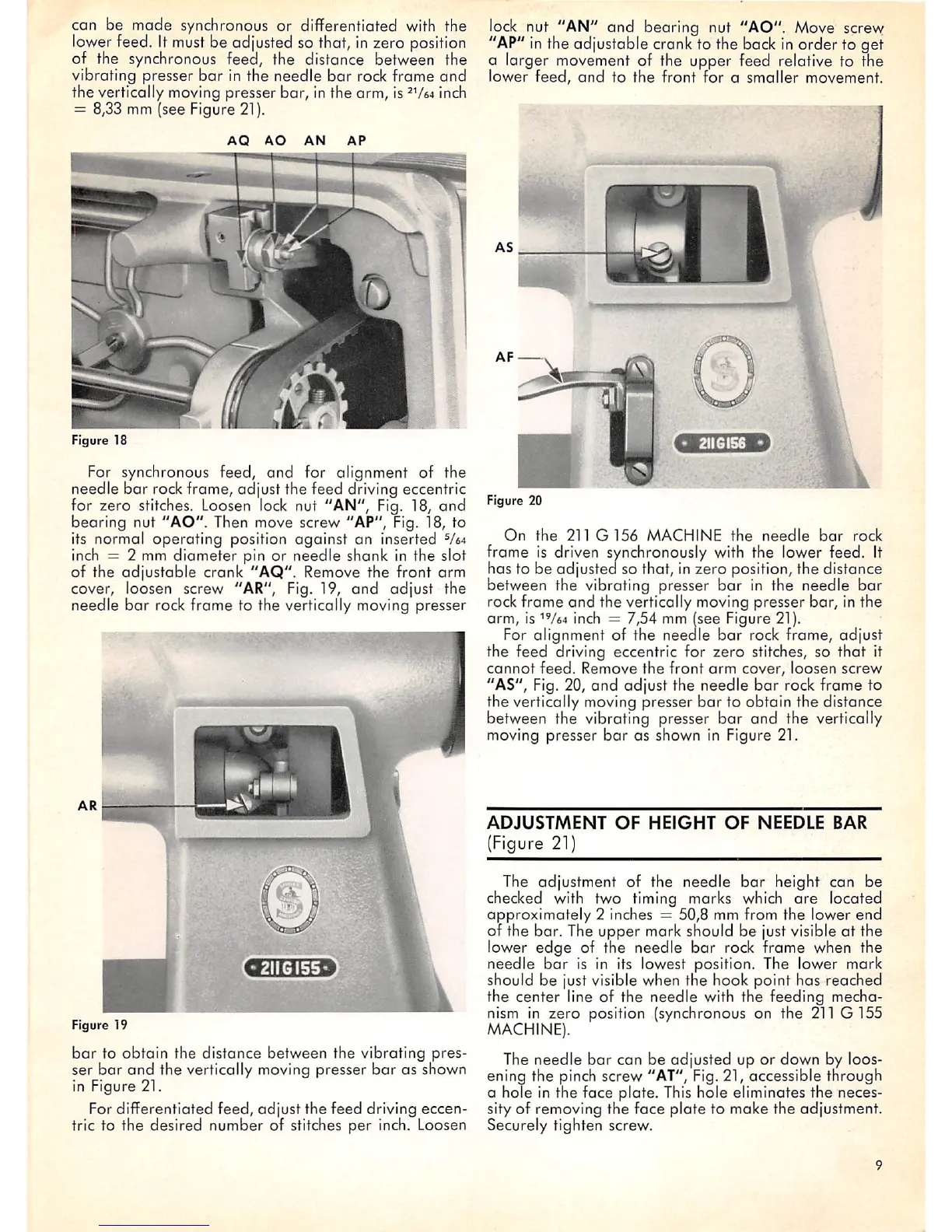

Figure 18

For synchronous feed, and for alignment of the

needle bar rock frame, adjust the feed driving eccentric

for zero stitches. Loosen

lock

nut "AN", Fig. 18, and

bearing nut "AO". Then move screw "AP", Fig. 18, to

its normal operating position against an inserted

V64

inch = 2 mm diameter pin or needle shank in the slot

of the

adjustable

crank

"AQ".

Remove the front arm

cover, loosen screw "AR", Fig. 19,

and

adjust the

needle

bar

rock frame to the vertically moving presser

Figure 19

bar

to obtain the distance between the vibrating pres

ser

bar

and

the vertically moving presser

bar

as shown

in Figure 21.

For differentiated feed, adjust the feed driving eccen

tric to the desired number of stitches per inch. Loosen

lock nut "AN" and bearing nut "AO". Move

screvy

"AP" in the adjustable crank to the back in order to get

a larger movement of the upper feed relative to the

lower

feed,

and

to

the

front for a

smaller

movement.

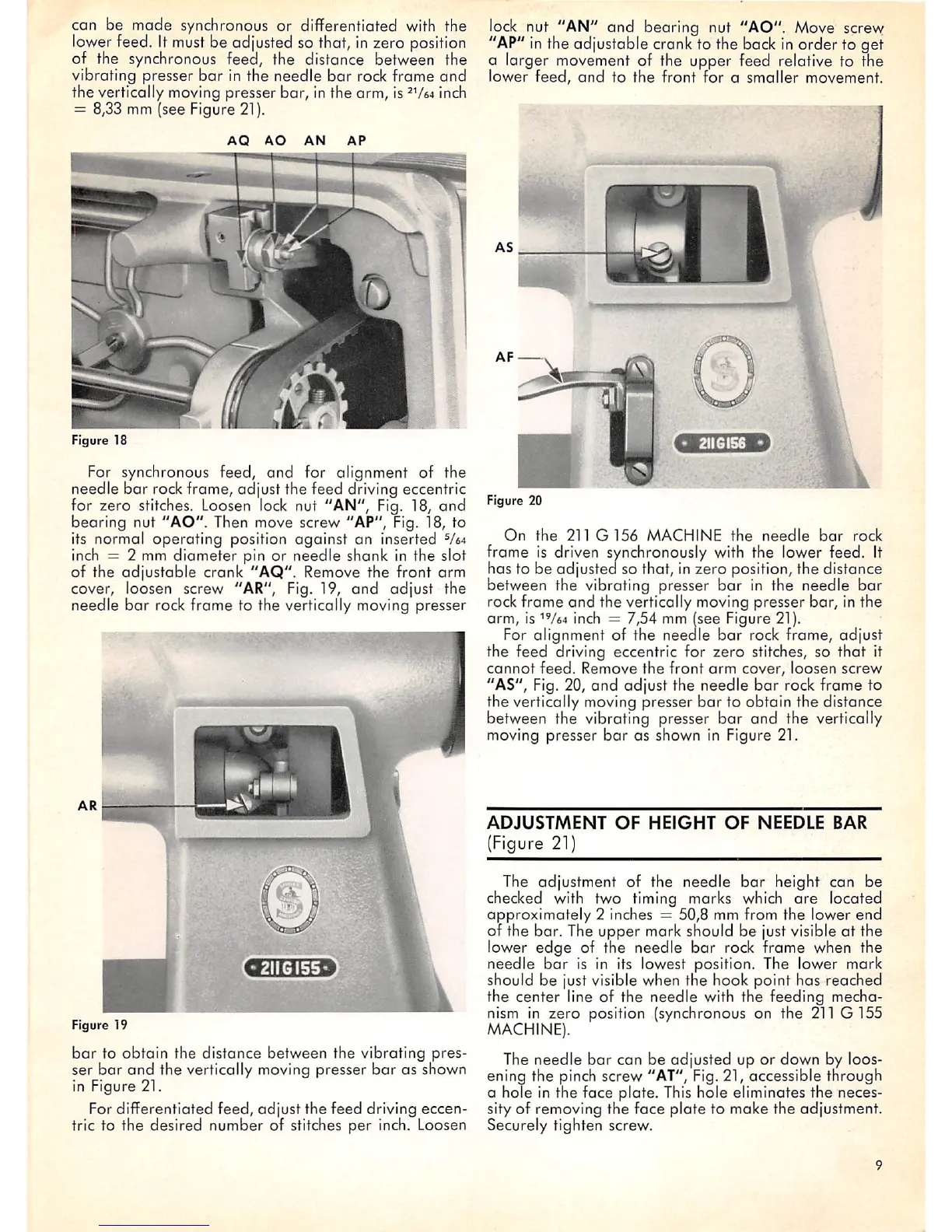

Figure 20

On

the

211

G156

MACHINE

the

needle

bar

rock

frame

is

driven

synchronously

with

the

lower

feed.

It

has to be adjusted so that, in zero position, the distance

between the vibrating presser

bar

in the needle

bar

rock

frame

and

the vertically moving presser

bar,

in the

arm, is

^V64

Inch = 7,54 mm (see Figure 21).

For alignment of the needle

bar

rock frame, adjust

the feed driving eccentric for zero stitches, so that it

cannot

feed.

Remove

the

front

arm

cover,

loosen

screw

"AS", Fig. 20,

and

adjust the needle

bar

rock frame to

the vertically moving presser

bar

to obtain the distance

between the vibrating presser

bar

and the vertically

moving presser

bar

as shown In Figure 21.

ADJUSTMENT

OF

HEIGHT

OF

NEEDLE

BAR

(Figure 21)

The adjustment of the

needle

bar

height can be

checked with two timing marks which

are

located

approximately

2 inches = 50,8 mm from the lower end

of the bar. The upper mark should be just visible at the

lower

edge

of the needle

bar

rock frame when the

needle

bar

is in its lowest position. The lower mark

should be just visible when the hook point has reached

the center line of the needle with the feeding mecha

nism in zero position (synchronous on the

211

G155

MACHINE).

The needle

bar

can be adjusted up or down by loos

ening the pinch screw "AT", Fig. 21, accessible through

a hole in the face plate. This hole eliminates the neces

sity of removing the face plate to make the adjustment.

Securely tighten screw.

Loading...

Loading...