TO WIND

THE

BOBBIN

(Figure 9)

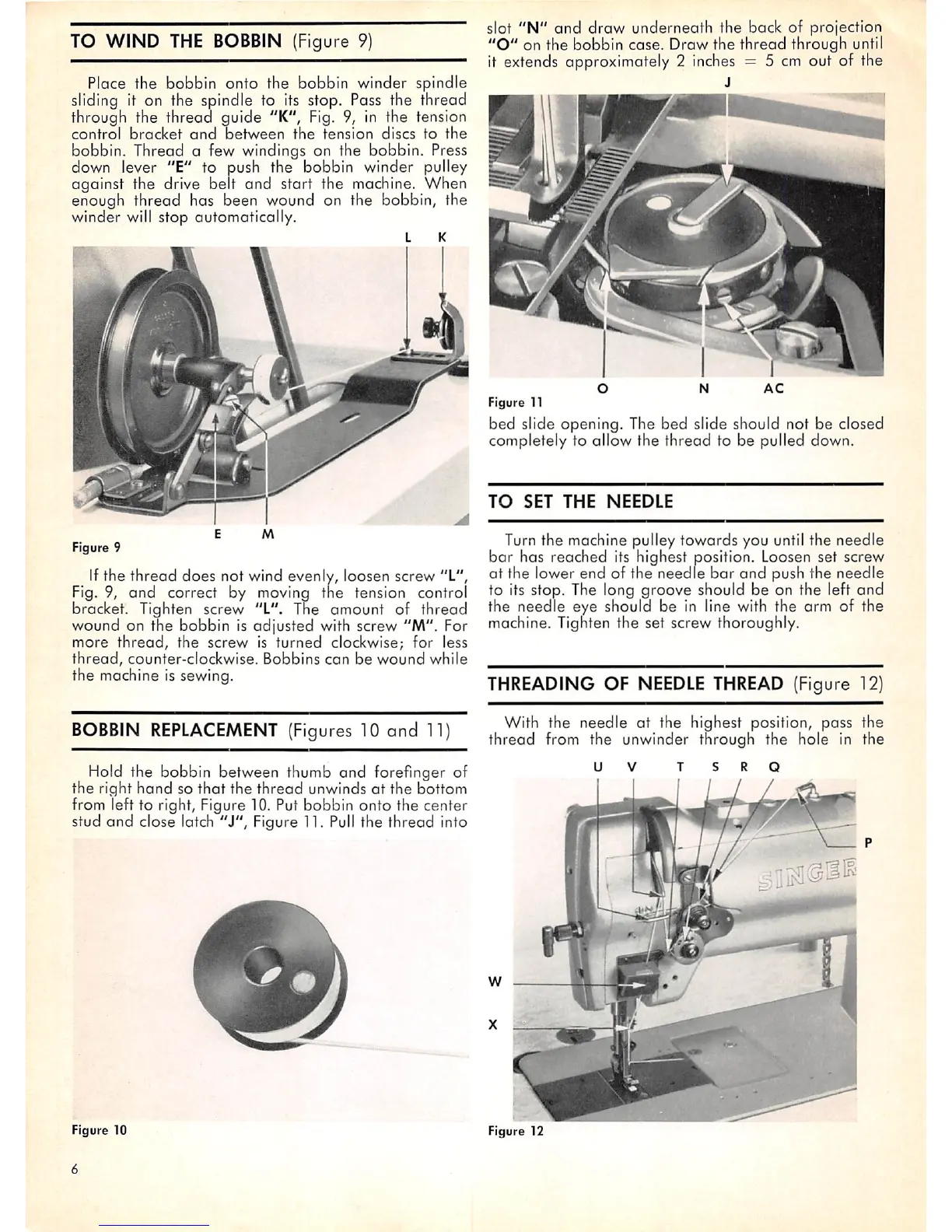

Place the bobbin onto the bobbin winder spindle

sliding it on the spindle to its stop. Pass the thread

through the thread guide "K", Fig. 9, in the tension

control

bracket

and

between

the

tension

discs

to

the

bobbin. Thread a few windings on the bobbin. Press

down lever "E" to push the bobbin winder pulley

against the

drive

belt and start the

machine.

When

enough thread has been wound on the bobbin, the

winder will stop automatically.

Figure 9

Ifthe thread does not wind evenly, loosen screw "L",

Fig.

9, and correct by

moving

the tension control

bracket. Tighten screw "L". The amount of thread

wound on the bobbin is adjusted with screw "M". For

more

thread,

the

screw

is

turned

clockwise; for less

thread,

counter-clockwise.

Bobbins

can

be

wound

while

the machine is sewing.

BOBBIN

REPLACEMENT

(Figures 10 and

11)

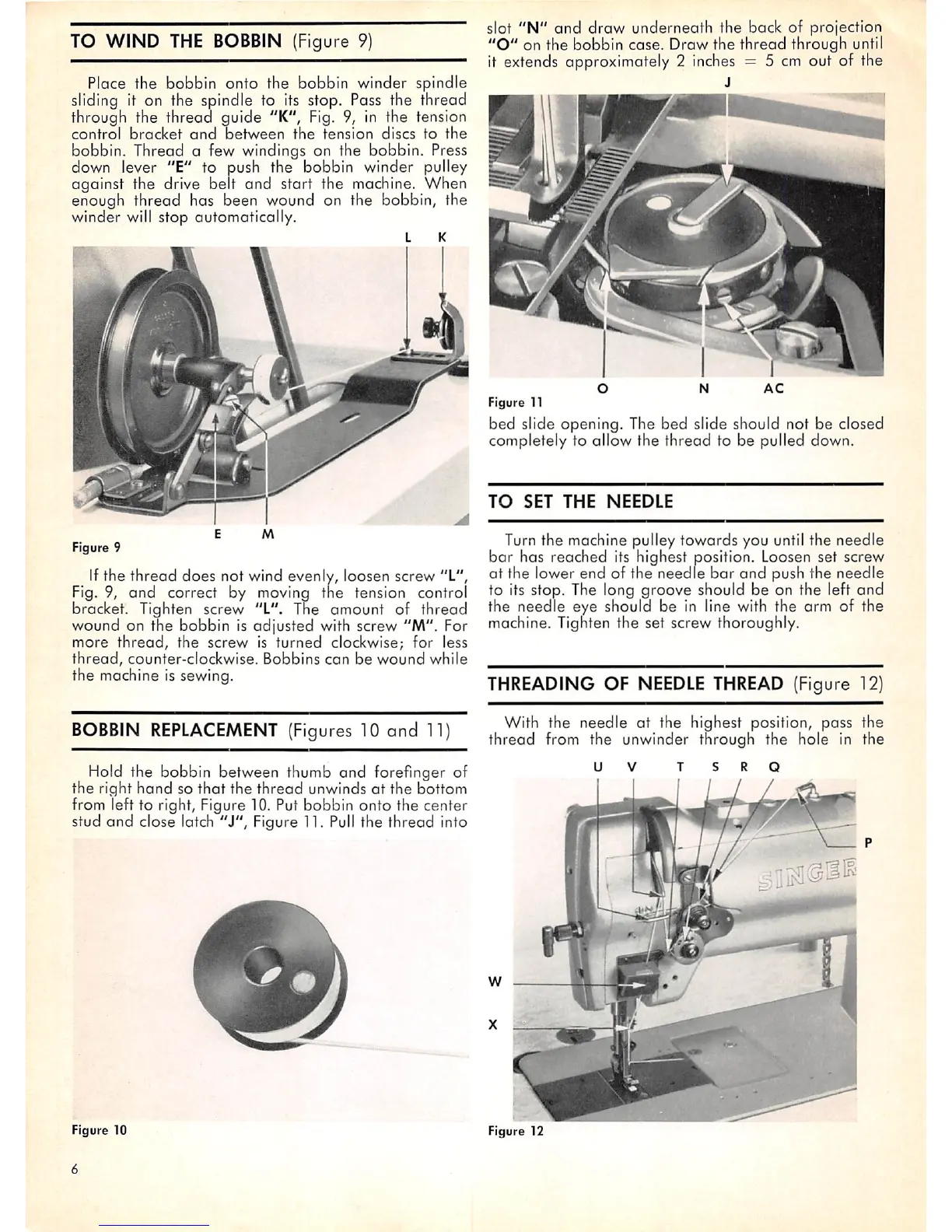

Hold the bobbin between thumb and forefinger of

the right

hand

so

that

the

thread

unwinds at the bottom

from left to right. Figure 10. Put bobbin onto the center

stud

and

close latch

"i",

Figure 11.

Pull

the thread into

Figure 10

6

slot

"N"

and

draw

underneath

the back of projection

"O"

on the bobbin case. Draw the thread through

until

it extends approximately 2

Inches

= 5 cm out of the

J

Figure 11

bed slide opening. The bed slide should not be closed

completely to allow the thread to be pulled down.

TO

SET

THE

NEEDLE

Turn the machine pulley towards you until the needle

bar

has reached its highest position. Loosen set screw

at

the lower end of the

needle

bar

and

push the

needle

to its stop. The long groove should be on the left

and

the needle eye should be in line with the arm of the

machine. Tighten the set screw thoroughly.

THREADING

OF

NEEDLE

THREAD

(Figure 12)

With the needle at the highest position, pass the

thread

from the unwinder through the hole in the

Figure 12

Loading...

Loading...