SETTING

THE

CLEARANCE

BETWEEN

NEEDLE

AND HOOK

POINT

(Continued)

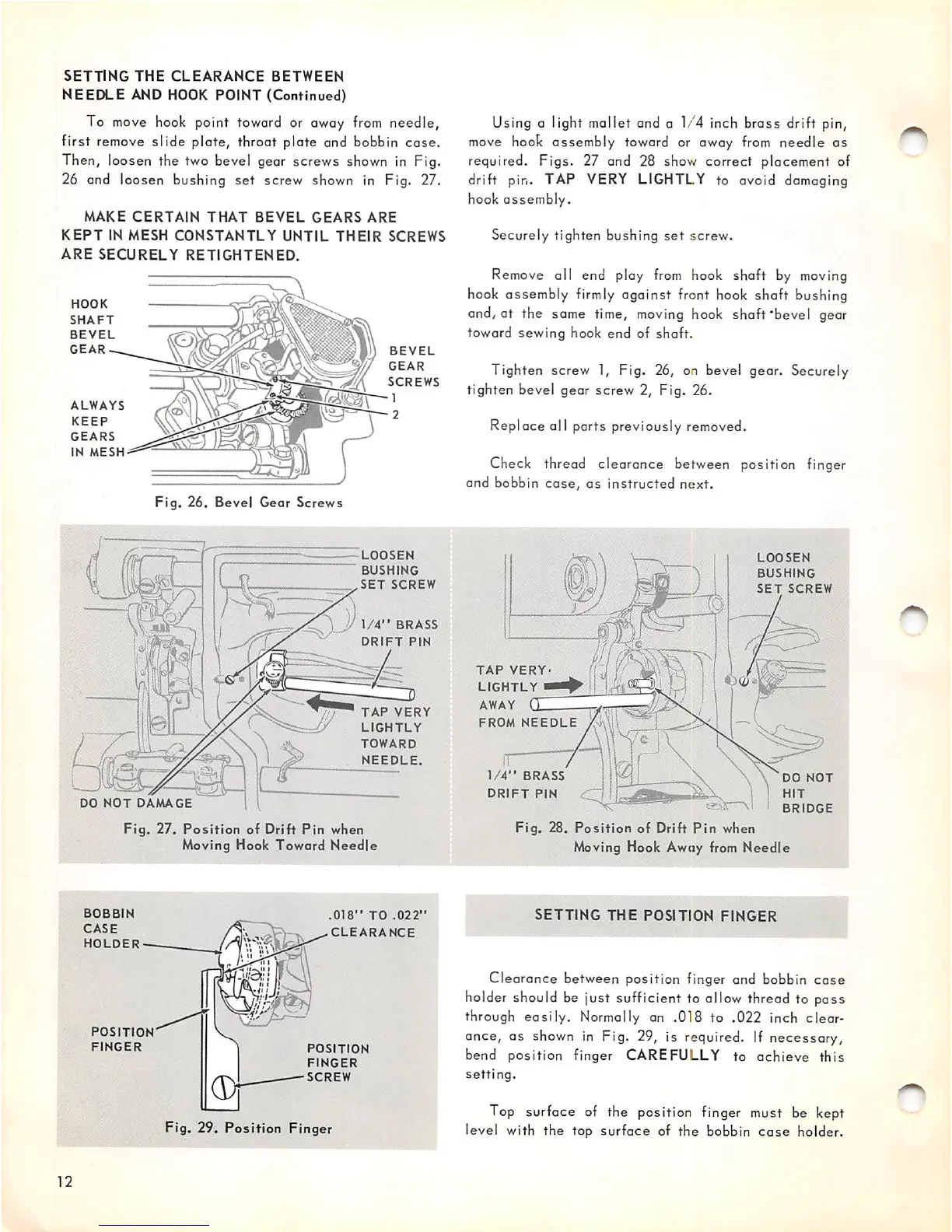

To move hook point toward or away

from

needle,

first remove

slide

plate, throat plate and bobbin

case.

Then, loosen the two bevel gear screws shown in Fig.

26 and loosen bushing set screw shown in Fig. 27.

MAKE

CERTAIN

THAT

BEVEL

GEARS

ARE

KEPT

IN MESH

CONSTANTLY

UNTIL

THEIR

SCREWS

ARE

SECURELY

RETIGHTENED.

HOOK

SHAFT

BEVEL

GEAR

BEVEL

GEAR

SCREWS

ALWAYS

KEEP

^ ^

GEARS

IN

MESH

Fig.

26. Bevel Geor

Screws

LOOSEN

BUSHING

SET

SCREW

1/4"

BRASS

DRIFT

PIN

TAP

VERY

LIGHTLY

TOWARD

NEEDLE.

DO

NOT

DAMAGE

12

Fig.

27.

Position

of Drift

Pin

when

Moving Hook

Toward

Needle

BOBBIN

CASE

HOLDER

POSITION

FINGER

1

.018"

TO

.022"

CLEARANCE

POSITION

FINGER

SCREW

Fig. 29.

Position

Finger

Using a light mallet and a 1/4 inch brass drift pin,

move

hook assembly toward or away

from

needle as

required. Figs. 27 and 28 show correct placement of

drift pin. TAP VERY LIGHTLY to avoid damaging

hook

assembly.

Securely tighten bushing

set

screw.

Remove all end play

from

hook shaft by moving

hook assembly

firmly

against front hook shaft bushing

and, at the some time,

moving

hook shaft'bevel gear

toward sewing hook end of shaft.

Tighten screw 1, Fig. 26, on bevel gear. Securely

tighten bevel

gear

screw 2, Fig. 26.

Replace all parts previously removed.

Check thread clearance between position finger

and

bobbin

case,

as

instructed

next.

TAP

VERY

LIGHTLY

AWAY

QZ

FROM

NEEDLE

1/4"

BRASS

DRIFT

PIN

LOOSEN

BUSHING

SET

SCREW

DO

NOT

HIT

BRIDGE

Fig.

28.

Position

of Drift

Pin

when

Moving Hook Away

from

Needle

SETTING

THE

POSITION

FINGER

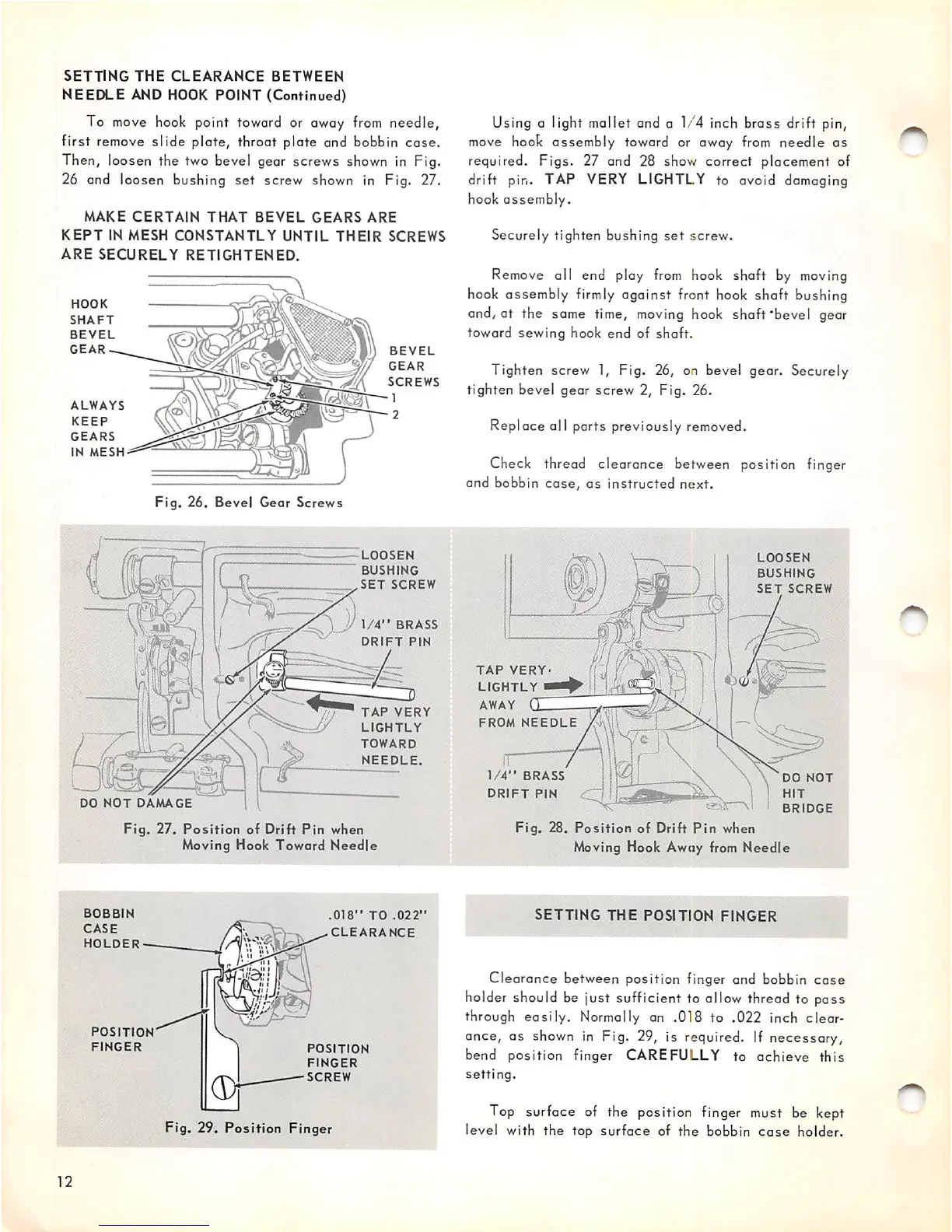

Clearance

between position finger and bobbin

case

holder should be just sufficient to allow thread to pass

through easily. Normally an .018 to .022 inch clear

ance, as shown in Fig. 29, is required. If necessary,

bend position finger CAREFULLY to achieve this

setting.

Top surface of the position finger must be kept

level with

the

top

surface

of the bobbin

case

holder.

Loading...

Loading...