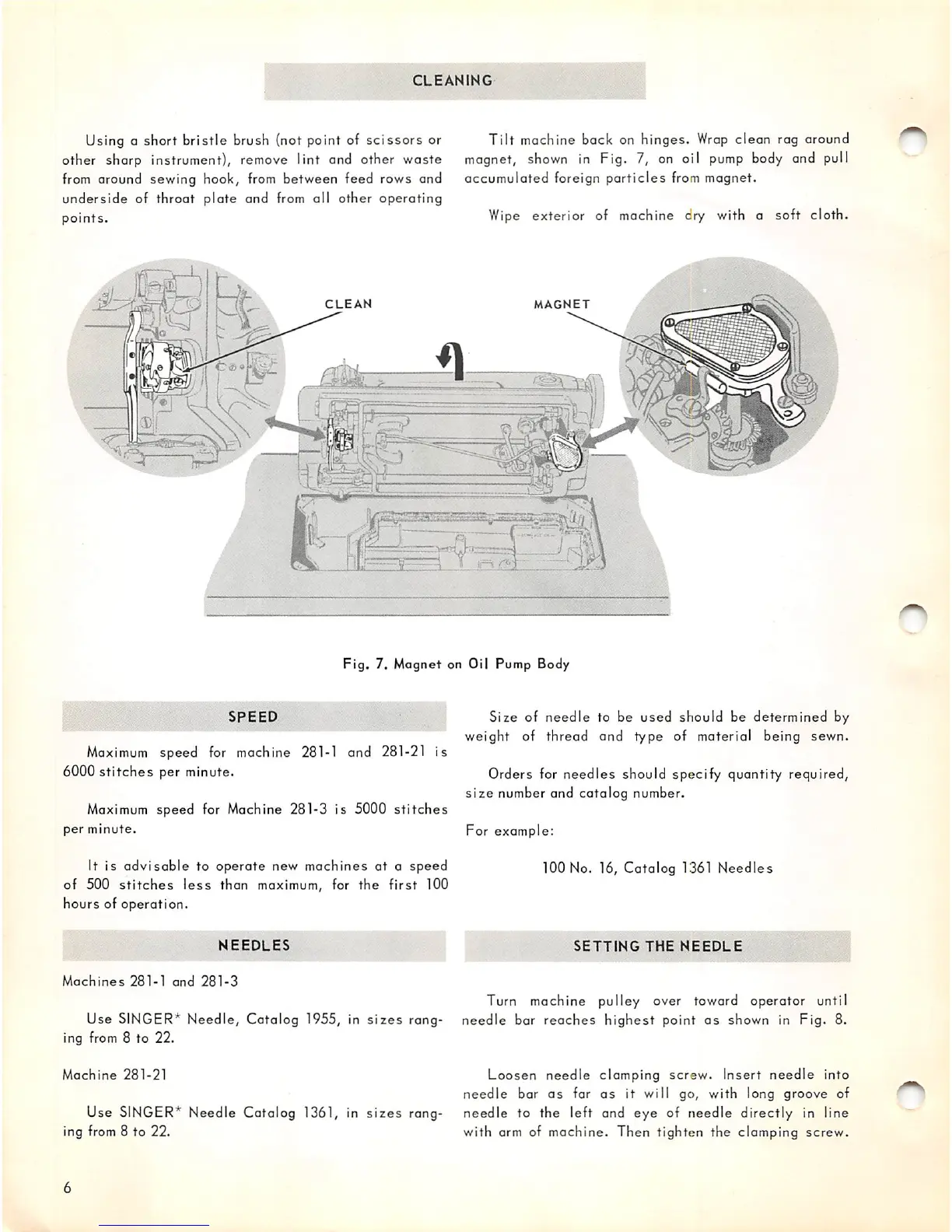

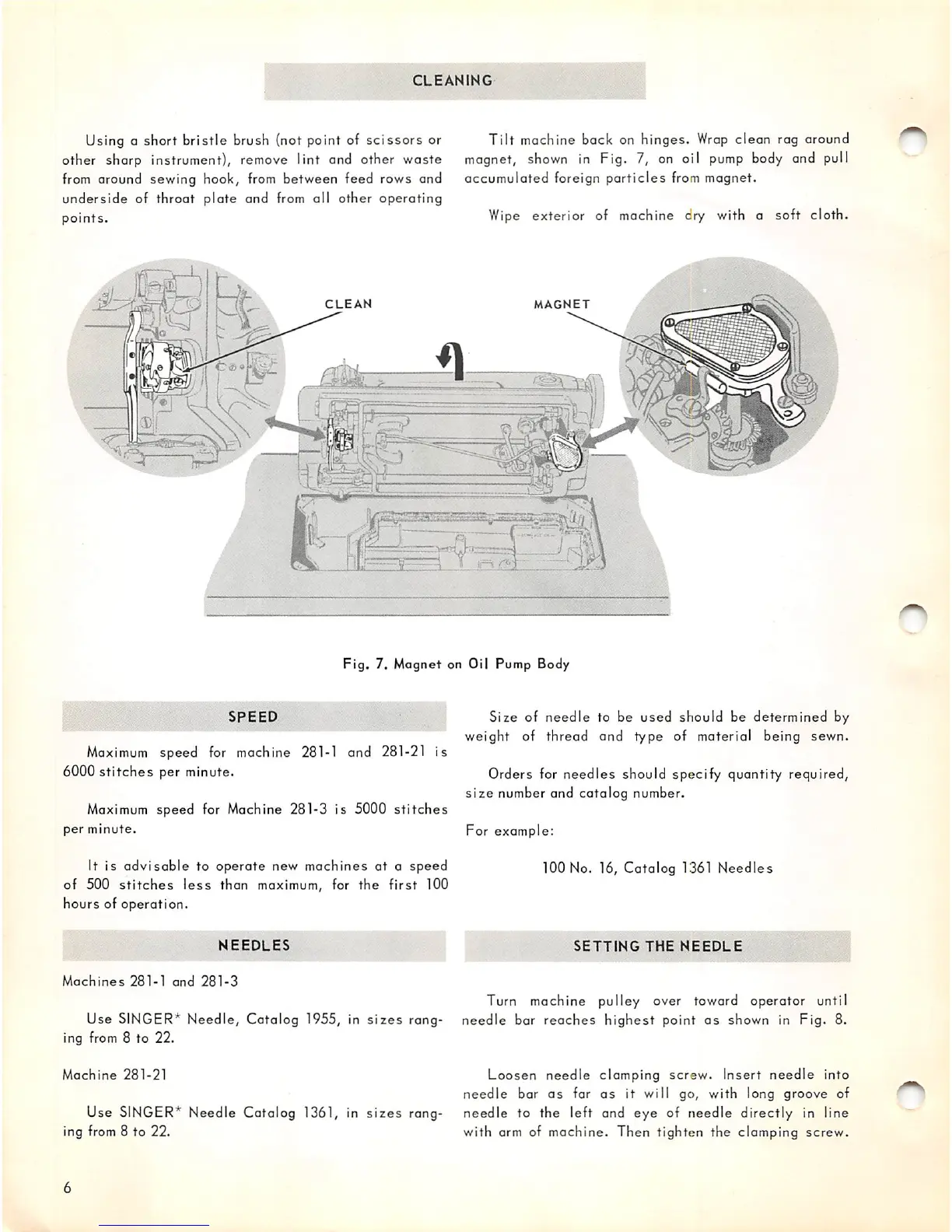

CLEANING

Using a short bristle brush (not point of

scissors

or

Tilt

machine back on hinges.

Wrap

clean rag around

other sharp instrument),

remove

lint and other waste magnet,

shown

in Fig. 7, on oil

pump

body

and

pul

from

around sewing hook,

from

between feed rows and accumulated foreign particles

from

magnet.

underside

of

throat

plate

and from all

other

operating

points.

CLEAN

Wipe

exterior of machine dry with a soft cloth.

MAGNET

Fig.

7. Magnet on Oil Pump Body

SPEED

Maximum

speed for machine 281-1 and 281-21 is

6000

stitches

per minute.

Maximum

speed for Machine 281-3 is 5000

stitches

per

minute.

It is

advisable

to

operate

new

machines

at a

speed

of 500

stitches

less

than maximum, for

the

first

100

hours of

operation.

NEEDLES

Machines

281-1

and

281-3

Use SINGER* Needle, Catalog 1955, in

sizes

rang

ing from 8 to 22.

Machine

281-21

Use SINGER* Needle Catalog 1361, in

sizes

rang

ing from 8 to 22.

Size of

needle

to be used should be determined by

weight of thread and type of material being sewn.

Orders for

needles

should specify quantity required,

size

number and catalog number.

For

example:

100 No. 16,

Catalog

1361

Needles

SETTING

THE

NEEDLE

Turn machine pulley over toward operator until

needle

bar

reaches

highest

point

as

shown in

Fig.

8.

Loosen

needle

clamping

screw.

Insert

needle

into

needle

bar

as

far

as

it will go, with long groove of

needle

to

the

left

and

eye

of

needle

directly

in line

with arm of

machine.

Then

tighten

the clamping

screw.

Loading...

Loading...