TIMING

THE

MACHINE

Timing the machine

consists

of first

adjusting

the

radial

position

of sewing hook with

relation

to move

ment of

needle

bar and

needle

thread

take-up

lever, to

make certain that loop of thread formed by needle will

be correctly taken by point of hook at proper time.

The check spring and feed

are

then timed to syn

chronize

their

motions

with

needle

and

hook

movement.

TIMING

THE

SEWING

HOOK

Remove slide plate, throat plate, presser foot and

feed dog.

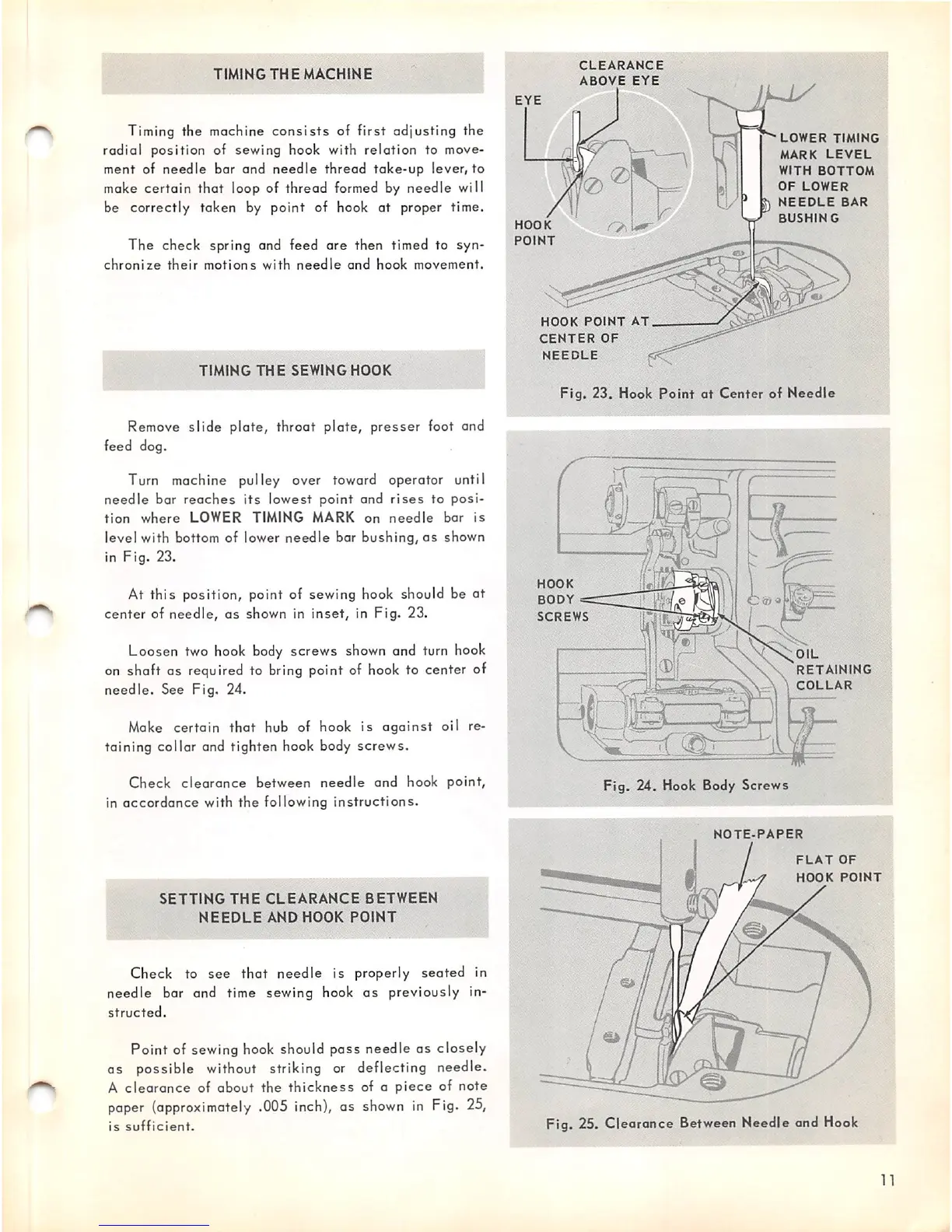

Turn machine pulley over toward operator until

needle

bar

reaches

its

lowest

point

and

rises

to

posi

tion

where

LOWER

TIMING

MARK

on

needle

bar

is

level with bottom of lower

needle

bar

bushing,

as

shown

in Fig. 23.

At

this

position, point of sewing hook should be

at

center

of

needle,

as shown in

inset,

in Fig. 23.

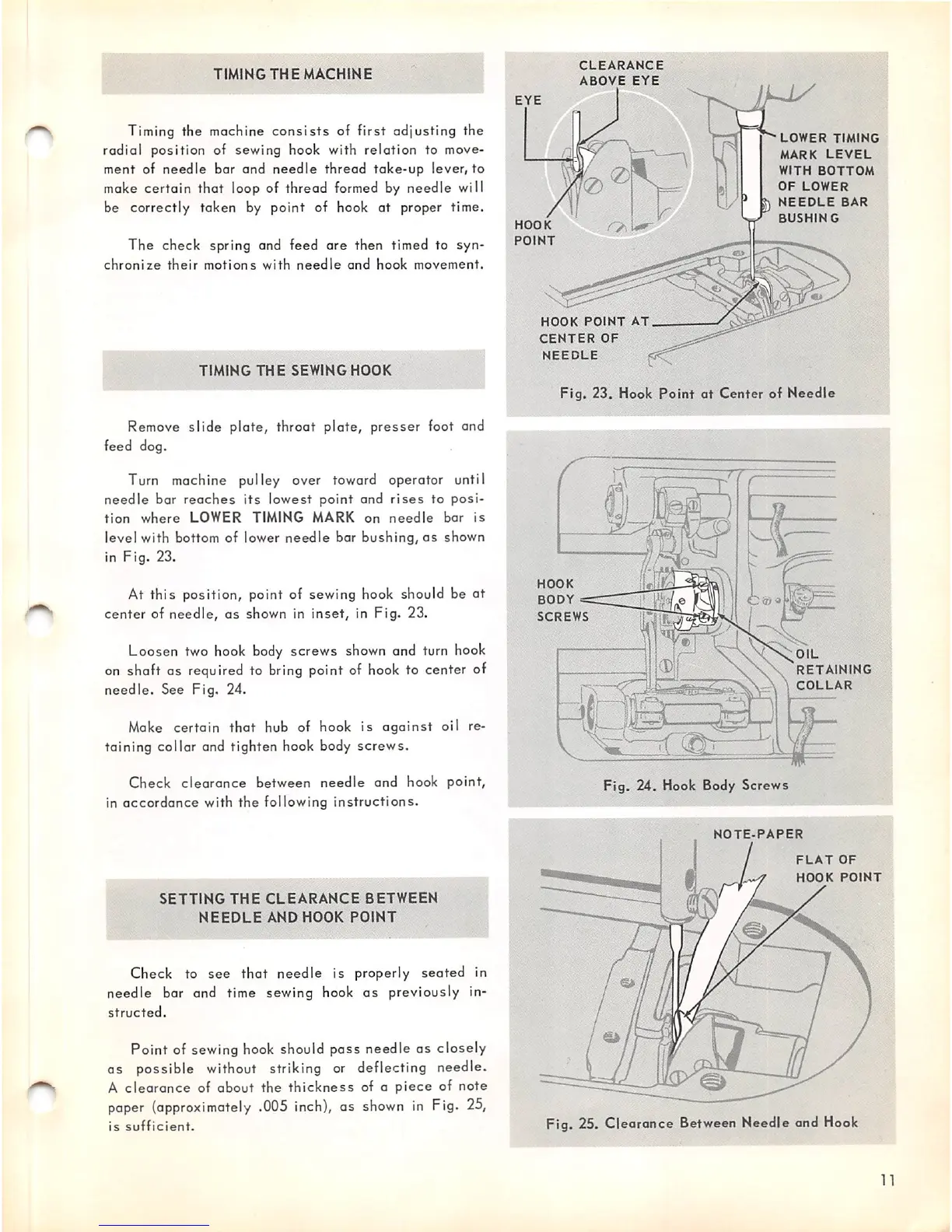

Loosen two hook

body

screws shown and turn hook

on shaft as required to bring point of hook to center of

needle.

See

Fig.

24.

Make certain

that

hub of hook is

against

oil re

taining collar and tighten hook body screws.

Check

clearance

between

needle

and

hook

point,

in

accordance

with

the

following

instructions.

SETTING

THE

CLEARANCE

BETWEEN

NEEDLE

AND

HOOK

POINT

Check to

see

that needle is properly seated in

needle bar and time sewing hook as previously in

structed.

Point of sewing hook should pass needle as closely

as possible without striking or deflecting needle.

A

clearance

of about the

thickness

of a

piece

of note

paper (approximately .005

inch),

as

shown

in

Fig.

25,

is

sufficient.

EYE

HOOK

POINT

CLEARANCE

ABOVE

EYE

HOOK

POINT

AT

CENTER

OF

NEEDLE

LOWER

TIMING

MARK

LEVEL

WITH

BOTTOM

OF

LOWER

^

NEEDLE

BAR

BUSHING

Fig.

23. Hook

Point

at

Center

of

Needle

HOOK

BODY

SCREWS

Fig.

24. Hook Body Screws

OIL

RETAINING

COLLAR

NOTE-PAPER

FLAT

OF

HOOK

POINT

Fig. 25. Clearance Between Needle and

Hook

11

Loading...

Loading...