INSTALLATION

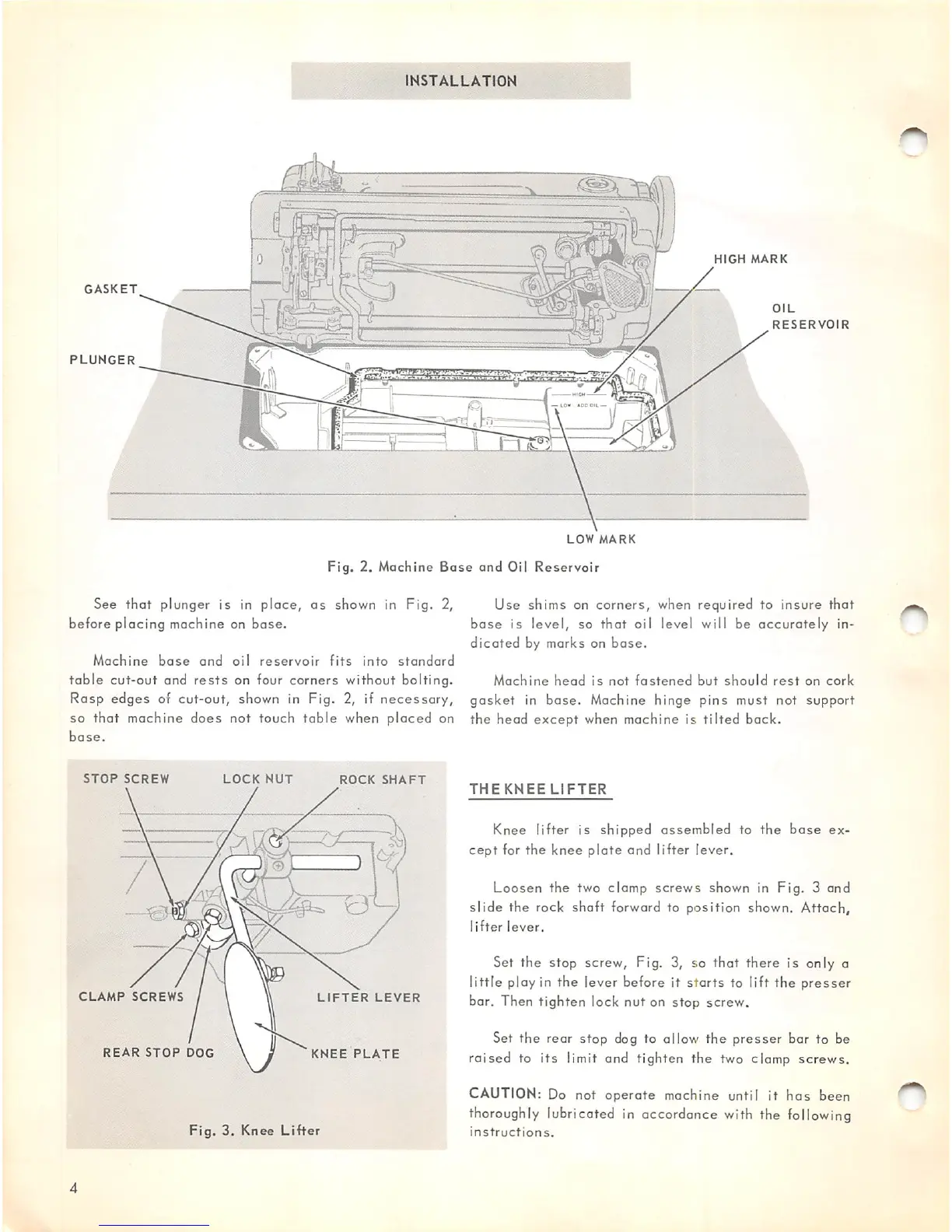

GASKET

PLUNGER

HIGH

MARK

OIL

RESERVOIR

LOW

MARK

Fig.

2. Machine

Base

and

Oil

Reservoir

See that plunger is in place, as shown in Fig. 2, Use shims on corners, when required to insure that

before placing machine on

base,

base

is level, so

that

oil level will be

accurately

in

dicated

by marks on

bose.

Machine

base

and

oil

reservoir

fits

into

standard

table

cut-out and

rests

on four corners without bolting. Machine head is not

fastened

but should

rest

on cork

Rasp edges of cut-out, shown in Fig. 2, if necessary, gasket in base. Machine hinge pins must not support

so that machine does not touch table when placed on the head except when machine is tilted back,

base.

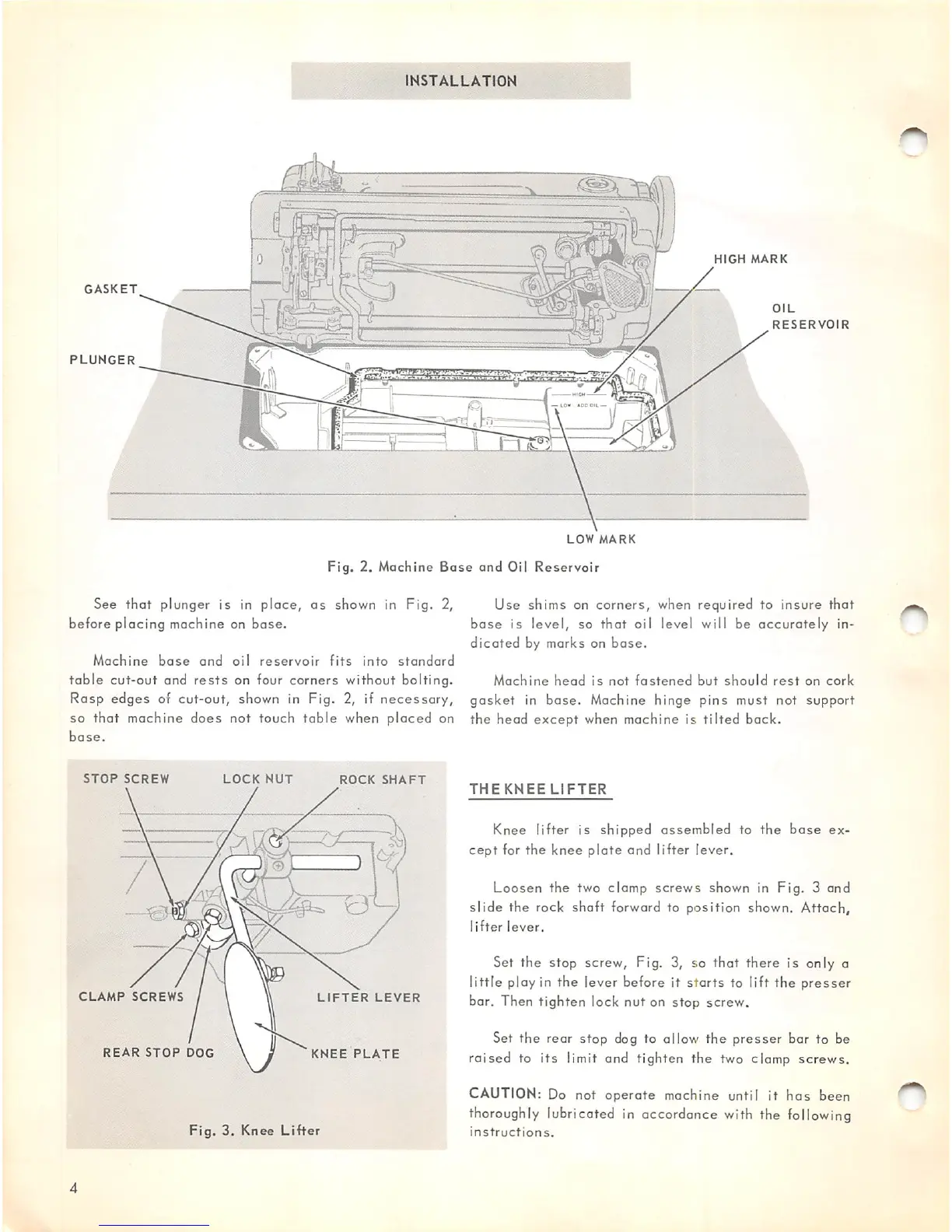

STOP

SCREW

LOCK

NUT

ROCK

SHAFT

CLAMP

SCREWS

LIFTER

LEVER

REAR

STOP

DOG

KNEE

PLATE

Fig.

3,

Knee

Lifter

THEKNEE

LIFTER

Knee lifter is shipped

assembled

to

the

base

ex

cept

for

the

knee

plate

and

lifter

lever.

Loosen

the two clamp

screws

shown in

Fig.

3

and

slide

the rock shaft forward to position shown. Attach,

lifter

lever.

Set the stop screw, Fig. 3, so that there is only a

little

play in

the

lever before it

starts

to lift

the

presser

bar. Then tighten lock nut on stop screw.

Set

the

rear

stop

dog to allow

the

presser

bar

to be

raised to

its

limit and tighten the two clamp screws.

CAUTION: Do not

operate

machine until it

has

been

thoroughly

lubricated in accordance

with

the

following

instructions.

Loading...

Loading...