t

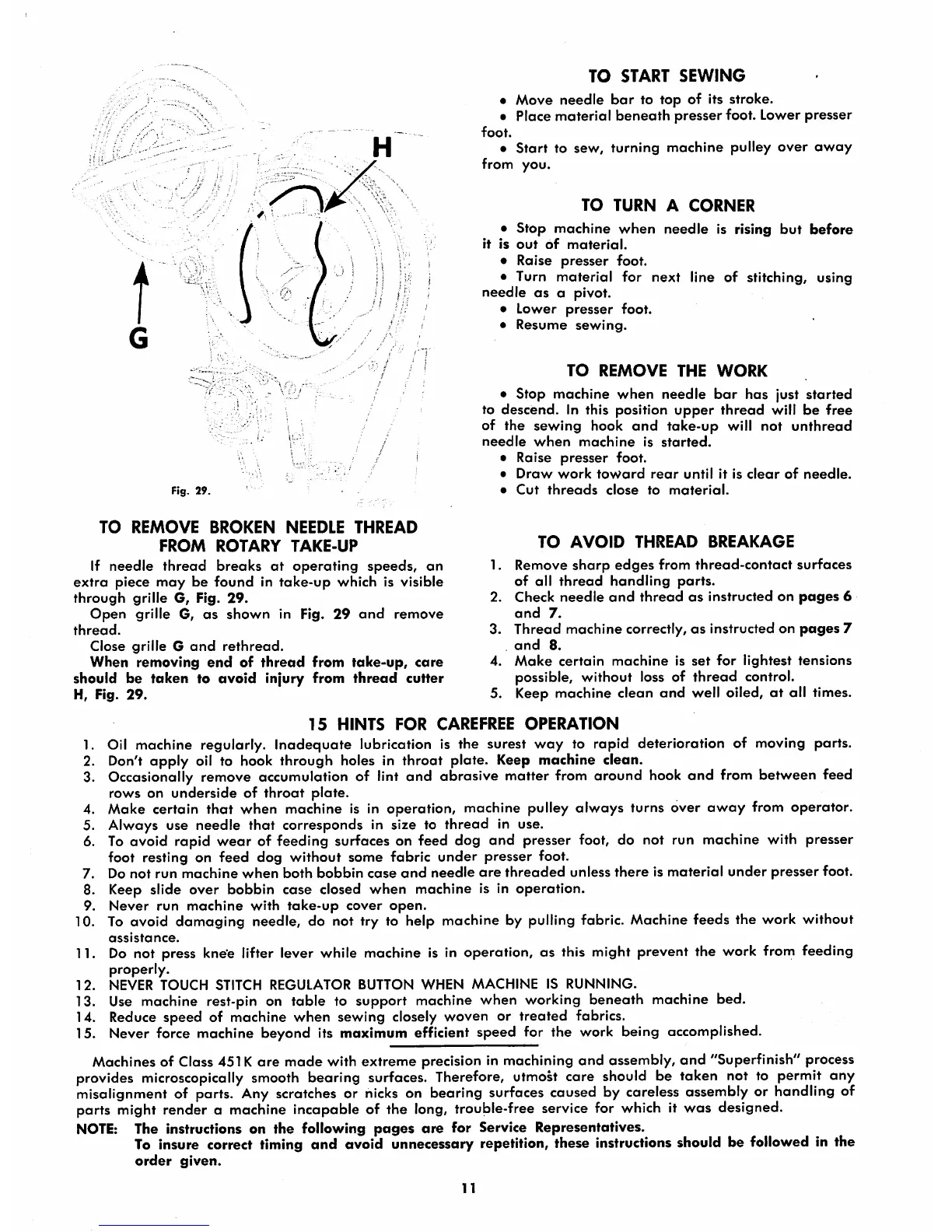

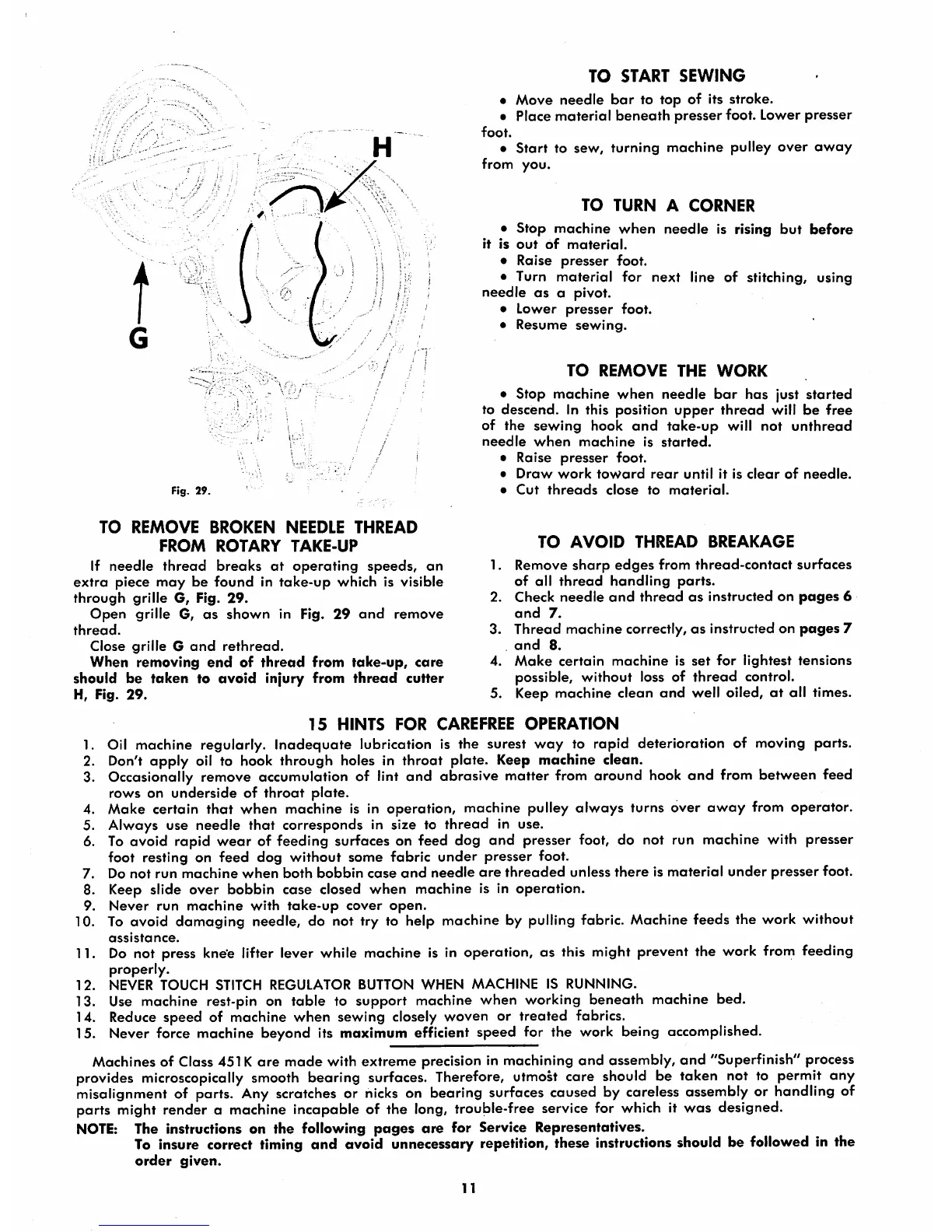

Fig.

29.

TO

REMOVE

BROKEN

NEEDLE

THREAD

FROM

ROTARY

TAKE-UP

If

needle

thread

breaks

at

operating

speeds,

an

extra

piece

may

be

found

in

take-up

which

is visible

through

grille

G, Fig.

29.

Open

grille G,

as

shown

in Fig.

29

and

remove

thread.

Close

grille

G

and

rethread.

When

removing

end

of

thread

from

take-up,

care

should be

taken

to

avoid

injury from

thread

cutter

H,

Fig.

29.

TO

START

SEWING

• Move

needle

bar

to top of its stroke.

• Place material

beneath

presser foot.

Lovy^er

presser

foot.

•

Start

to sew,

turning

machine

pulley

over

away

from you.

TO

TURN

A

CORNER

•

Stop

machine

when

needle

is rising

but

before

it

is

out

of

material.

• Raise

presser

foot.

• Turn

material

for

next line of stitching, using

needle

as

a pivot.

• Lower

presser

foot.

•

Resume

sewing.

TO

REMOVE

THE

WORK

• Stop

machine

when

needle

bar

has

just

started

to

descend.

In this position

upper

thread

will

be

free

of the

sewing

hook

and

take-up

will not

unthread

needle

when

machine

is

started.

• Raise

presser

foot.

•

Draw

work

toward

rear

until

it

is

clear

of

needle.

•

Cut

threads

close

to

material.

3.

4.

TO

AVOID

THREAD

BREAKAGE

Remove

sharp

edges

from

thread-contact

surfaces

of

all

thread

handling

parts.

Check

needle

and

thread

as

instructed on

pages

6

and

7.

Thread

machine

correctly,

as

instructed on

pages

7

and

8.

Make

certain

machine

is

set

for

lightest

tensions

possible, without loss of

thread

control.

Keep machine clean

and

well oiled,

at

all times.

15

HINTS

FOR

CAREFREE

OPERATION

1. Oil machine regularly. Inadequate lubrication is the surest way to rapid deterioration of moving parts.

2. Don't apply oil to hook through holes in throat plate. Keep machine clean.

3. Occasionally remove accumulation of lint and abrasive matter from around hook and from between feed

rows on

underside

of

throat

plate.

4. Make certain

that

when machine is in operation, machine pulley always turns over

away

from operator.

5. Always use needle that corresponds in size to thread in use.

6.

To

ovoid rapid wear of feeding surfaces on feed dog and presser foot, do not run machine with presser

foot resting on feed dog without some fabric

under

presser foot.

7. Do not run

machine

when

both

bobbin

case

and

needle

are

threaded

unless

there

is

material

under

presser

foot.

8. Keep slide over bobbin

case

closed

when

machine is in operation.

9.

Never

run

machine

with

take-up

cover

open.

10. To avoid damaging needle, do not try to help machine by pulling fabric. Machine feeds the work without

assistance.

11.

Do

not press

kne'e

lifter lever while machine is in operation, as this might prevent the work from feeding

properly.

12.

NEVER

TOUCH

STITCH

REGULATOR

BUTTON

WHEN

MACHINE

IS

RUNNING.

13.

Use

machine rest-pin on table to support machine when working beneath machine bed.

14. Reduce speed of machine when sewing closely woven or treated fabrics.

15. Never force machine beyond its maximum efficient speed for the work being accomplished.

Machines of Class 451K

are

made with extreme precision in machining and assembly,

and

"Superfinish" process

provides microscopically smooth bearing surfaces. Therefore, utmost care should be token not to permit any

misalignment of parts.

Any

scratches or

nicks

on bearing surfaces caused by careless assembly or handling of

ports might render a machine incapable of the long, trouble-free service for which it was designed.

NOTE:

The instructions on the following

pages

are

for Service Representatives.

To

insure correct timing and avoid unnecessary repetition, these instructions should be followed in the

order

given.

11

Loading...

Loading...