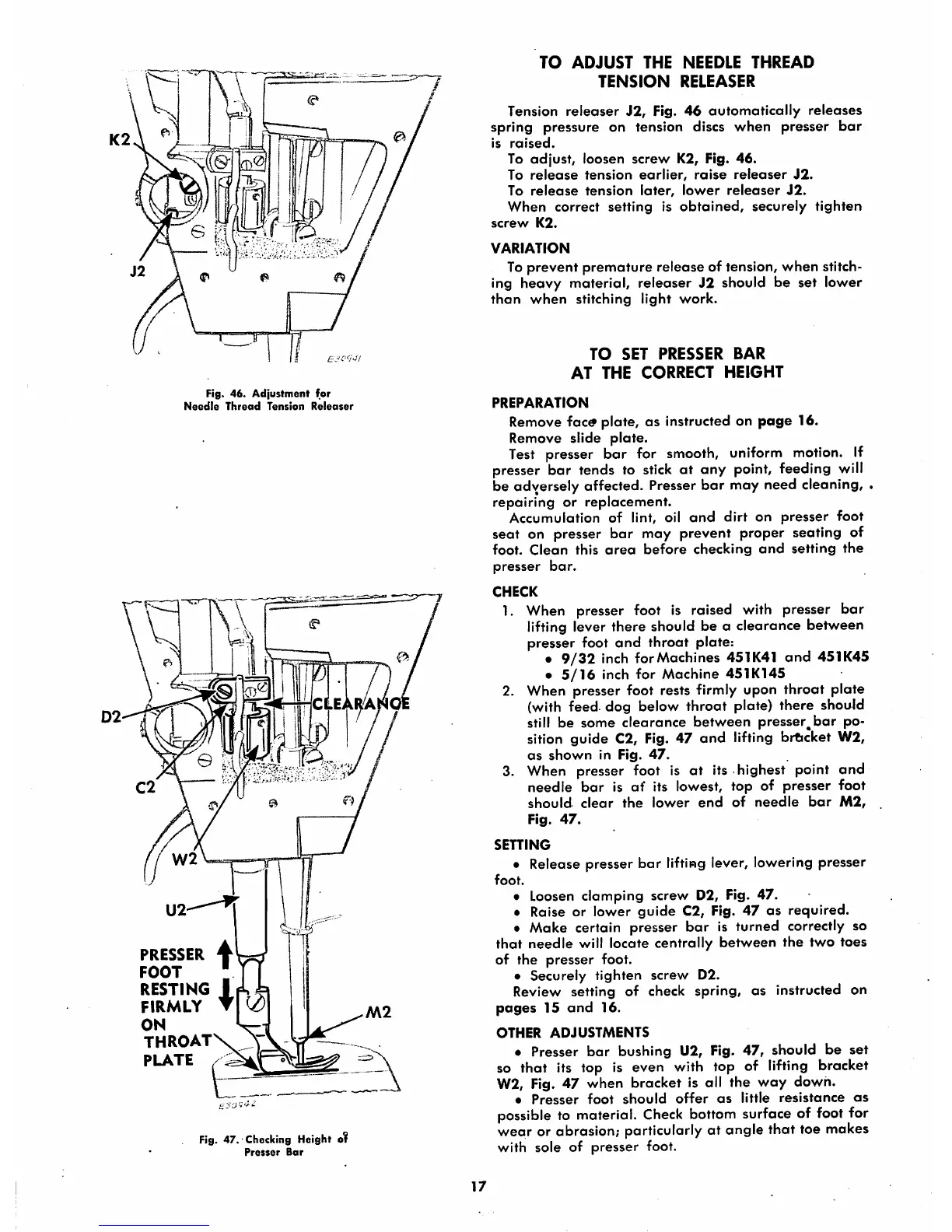

Fig. 46.

Adjustment

for

Needle

Thread

Tension

Releaser

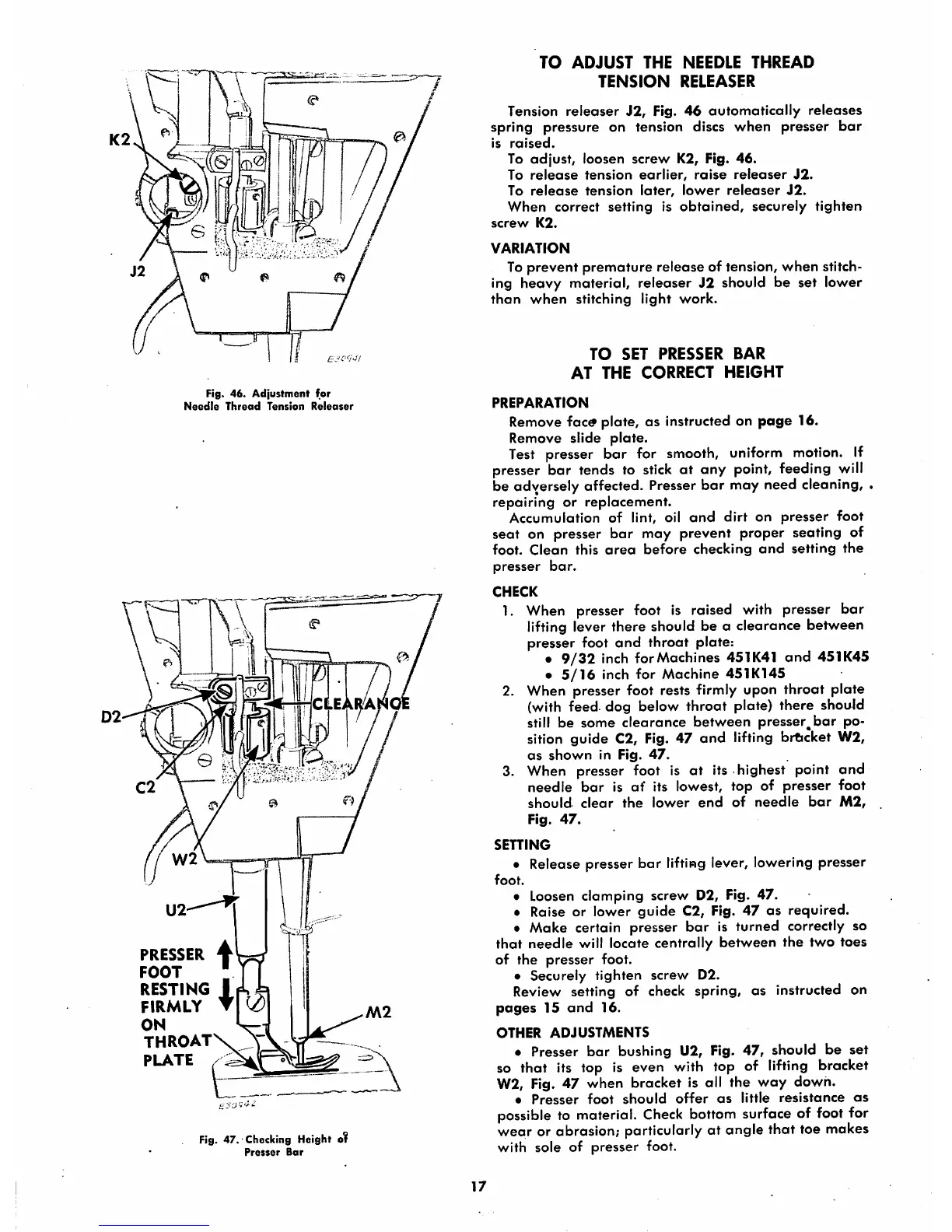

PRESSER

4

FOOT

•

RESTING

1

FIRMLY

T

ON

THROAT

PLATE

Fig.

47.'

Checking

Height

o?

Presser

Bar

TO

ADJUST

THE

NEEDLE

THREAD

TENSION

RELEASER

Tension

releaser

J2,

Fig.

46

automatically

releases

spring pressure on tension discs when presser

bar

is

raised.

To

adjust,

loosen

screw

K2, Fig.

46.

To

release

tension

earlier,

raise

releaser

J2.

To

release

tension

later,

lower

releaser

J2.

When correct setting is

obtained,

securely

tighten

screw

K2.

VARIATION

To

prevent

premature

release

of tension,

when

stitch

ing

heavy

material, releaser

J2

should be set lower

than

when

stitching

light

work.

TO

SET

PRESSER

BAR

AT

THE

CORRECT

HEIGHT

PREPARATION

Remove foctf plate, as instructed on

page

16.

Remove

slide

plate.

Test presser bar for smooth, uniform motion. If

presser bar tends to stick

at

any point, feeding will

be adversely affected. Presser

bar

may need cleaning, .

repairing

or

replacement.

Accumulation of lint, oil

and

dirt

on

presser

foot

seat on presser bar may prevent proper seating of

foot.

Clean

this

area

before

checking

and

setting

the

presser

bar.

CHECK

1. When presser foot is raised with presser bar

lifting lever there should be a clearance between

presser foot

and

throat

plate:

•

9/32

inch for Machines 451K4I

and

451K45

•

5/16

inch

for

Machine

451K145

2. When presser foot rests firmly upon throat plate

(with feed, dog below throat plate) there should

still be some clearance between presser^bar po

sition guide C2, Fig. 47

and

lifting bracket W2,

as

shown

in Fig.

47.

3. When presser foot is at its highest point and

needle

bar

is of its lowest, top of presser foot

should

clear

the

lower

end

of

needle

bar

M2,

Fig.

47.

SETTING

• Release presser

bar

lifting lever, lowering presser

foot.

• Loosen clamping screw D2, Fig. 47.

• Raise or lower

guide

C2, Fig. 47 as required.

• Make certain presser

bar

is turned correctly so

that

needle

will locate centrally

between

the

two toes

of the

presser

foot.

•

Securely

tighten

screw

D2.

Review setting of check spring, as instructed on

pages

15

and

16.

OTHER

ADJUSTMENTS

• Presser

bar

bushing U2, Fig. 47, should be set

so that its top is even with top of lifting bracket

W2, Fig. 47 when bracket is all the way down.

•

Presser

foot

should

offer

as

little

resistance

as

possible to material.

Check

bottom surface of foot for

wear or abrasion; particularly at angle that toe makes

with sole of

presser

foot.

17

Loading...

Loading...