SEHING

UP

DRIP

PAN

Position

drip

pan

on

underside

of

table,

as

shown

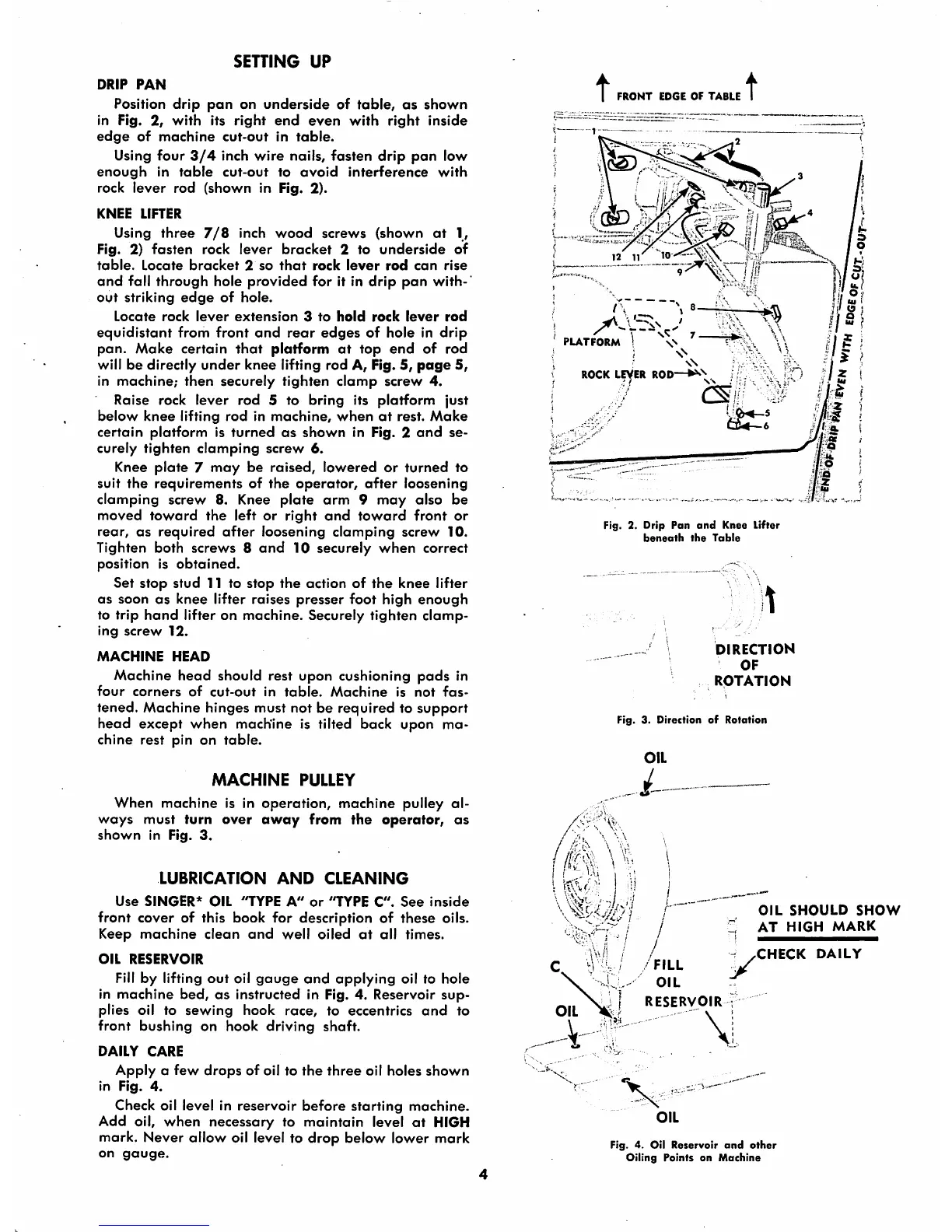

in Fig. 2,

with

its

right

end

even

with

right

inside

edge

of

machine

cut-out

in

table.

Using four

3/4

inch

wire

nails,

fasten

drip

pan

low

enough

in

table

cut-out

to

ovoid

interference

with

rock

lever

rod

(shown

in Fig. 2).

KNEE

LIFTER

Using

three

7/8

inch

wood

screws

(shown

at

1,

Fig. 2)

fasten

rock

lever

bracket

2 to

underside

of

table.

Locate

bracket

2

so

that

rock

lever

rod

can

rise

and

fall

through

hole

provided

for it in

drip

pan

with

out

striking

edge

of

hole.

Locate

rock

lever

extension

3

to

hold

rock

lever

rod

equidistant

from

front

and

rear

edges

of hole in

drip

pan.

Make

certain

that

platform

at

top

end

of

rod

will be directly

under

knee lifting rod A, Fig. 5,

page

5,

in

machine;

then

securely

tighten

clamp

screw

4.

Raise rock

lever

rod 5 to bring its

platform

just

below

knee

lifting

rod

in

machine,

when

at

rest.

Make

certain

platform

is

turned

as

shown

in Fig. 2

and

se

curely tighten

clamping

screw

6.

Knee

plate

7

may

be

raised,

lowered

or

turned

to

suit

the

requirements

of

the

operator,

after

loosening

clamping

screw 8. Knee

plate

arm

9

may

also

be

moved

toward

the

left

or

right

and

toward

front

or

rear,

as

required

after

loosening

clamping

screw

10.

Tighten both screws 8

and

10 securely

when

correct

position is

obtained.

Set

stop

stud 11 to stop

the

action of

the

knee

lifter

as soon

as

knee

lifter

raises

presser

foot

high

enough

to trip

hand

lifter on

machine.

Securely

tighten

clamp

ing

screw

12.

MACHINE

HEAD

Machine

head

should rest

upon

cushioning

pads

in

four

corners

of

cut-out

in

table.

Machine

is

not

fas

tened. Machine hinges must not be

required

to

support

head

except

when

machine is tilted back upon ma

chine

rest pin on

table.

MACHINE

PULLEY

When

machine

is in

operation,

machine

pulley al

ways

must

turn

over

away

from

the

operator,

as

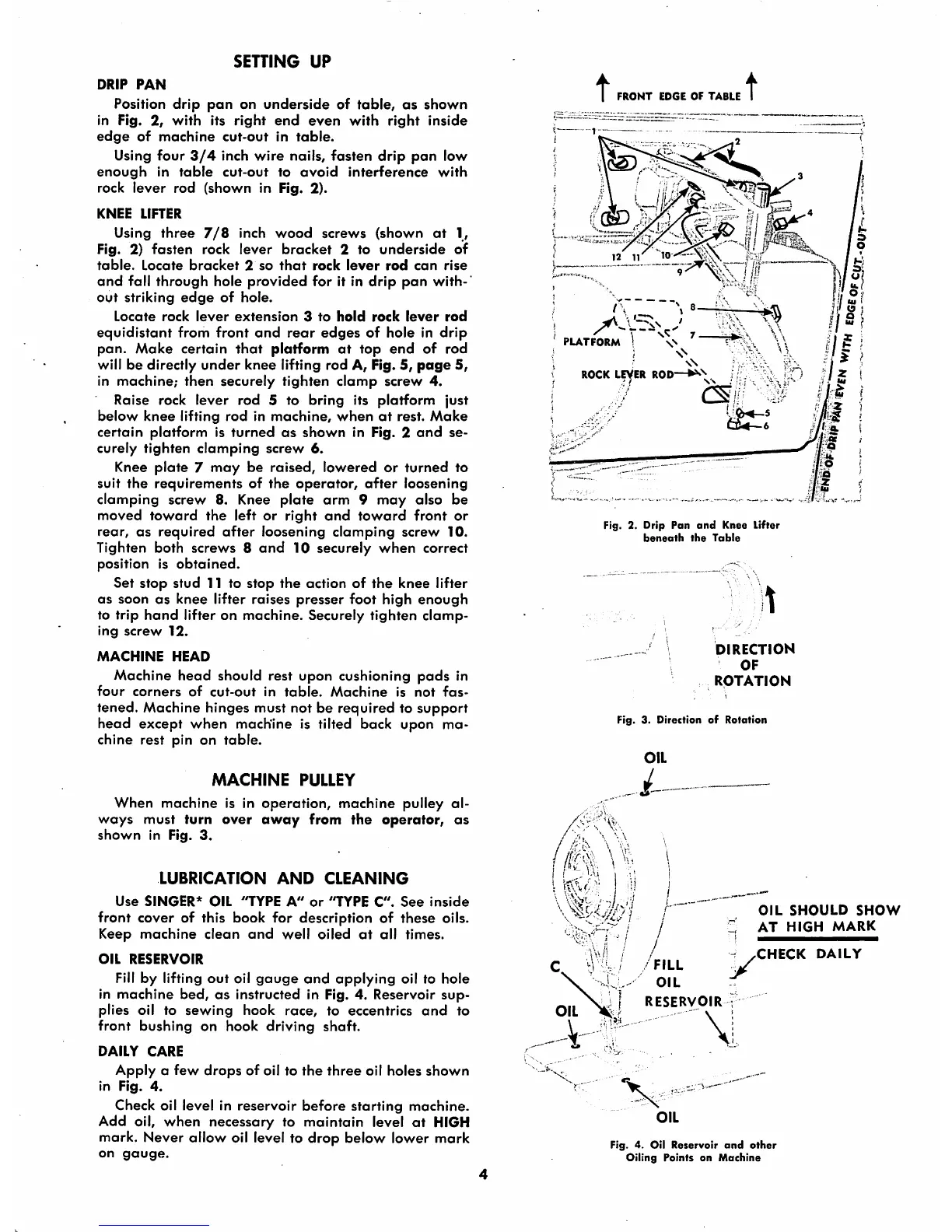

shown

in Fig.

3.

LUBRICATION

AND

CLEANING

Use

SINGER*

OIL

"TYPE

A"

or

'TYPE

C".

See

inside

front cover of this book

for

description of these oils.

Keep

machine

clean

and

well

oiled

at

all times.

OIL

RESERVOIR

Fill

by lifting

out

oil

gauge

and

applying oil to hole

in

machine

bed,

as

instructed in Fig. 4. Reservoir

sup

plies oil to

sewing

hook race, to eccentrics

and

to

front

bushing

on

hook

driving

shaft.

DAILY

CARE

Apply

a

few

drops

of

oil to

the

three

oil

holes

shown

in Fig.

4.

Check oil level in reservoir

before

starting

machine.

Add oil,

when

necessary to

maintain

level

at

HIGH

mark. Never allow oil level to

drop

below lower

mark

on

gauge.

t

FRONT

EDGE

OF

TABLE

12 11

t

PLATFORM

\N

t

ROCK

LEVER

ROD—

is

;

<TV

v<-

Fig. 2. Drip Pan

and

Knee Lifter

beneath

the

Table

it

. ^

DIRECTION

OF

ROTATION

Fig. 3. Direction of Rotation

//)7

' -

'I

- t

OIL

SHOULD

SHOW

AT

HIGH

MARK

CHECK

DAILY

FILL

RESERVOIR

OIL

Fig. 4. Oil

Reservoir

and

other

Oiling Points on

Machine

Loading...

Loading...