IrrtK-cc-c

1 ! i p

llirr

Fig. 5.

Priming

Points

beneath

Machine

Bed

OIL

/W\\

'•

///

) \l

/•///

I \

/ •!; a

ii

,^ir'

J

{r-

Fig. 6.

Bobbin

Winder

Lubrication

Fig. 7. Approximate Spray Pattern

p) I

Id

W Y y ^j

-•''—^^.-^^11

fX'

i

j ^

)7^

TTW-A11 \ti I

ir\¥4^zl±^Hi

''SU9/6

Fig. 8.

Rotary

Sewing

Hook

Cy

LUBRICATION

AND

CLEANING

(Cont'd)

AFTER

INSTALLATION

New

machines

and

machines

installed

after

several

weeks of idleness should be primed before using.

Residuallubricant may have congealed or disappeared

entirely.

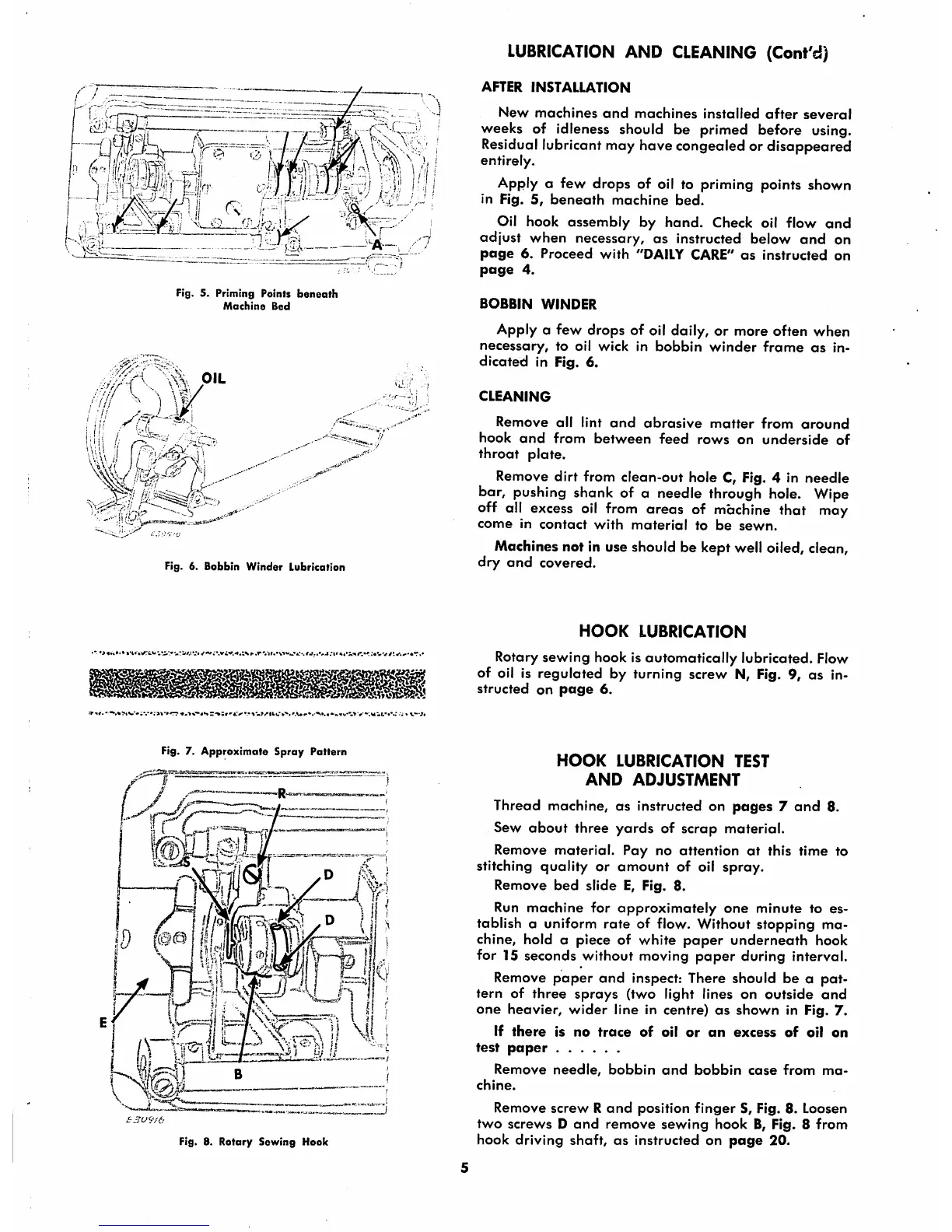

Apply a few drops of oil to priming points shown

in Fig.

5,

beneath

machine

bed.

Oil hook assembly by

hand.

Check oil flow

and

adjust

when necessary, as instructed below

and

on

page

6.

Proceed

with

"DAILY

CARE"

as

instructed

on

page

4.

BOBBIN

WINDER

Apply a few drops of oil daily, or more often when

necessary,

to oil

wick

in

bobbin

winder

frame

as

in

dicated in Fig. 6.

CLEANING

Remove

all

lint

and

abrasive

matter

from

around

hook

and

from

between

feed

rows

on

underside

of

throat

plate.

Remove dirt from clean-out hole C, Fig. 4 in

needle

bar, pushing shank of a needle through hole. Wipe

off all excess oil from areas of machine that may

come

in

contact

with

material

to

be

sewn.

Machines not in use should be kept well oiled, clean,

dry

and

covered.

HOOK

LUBRICATION

Rotary sewing hook is automatically lubricated. Flow

of oil is regulated by turning screw N, Fig. 9, as in

structed

on

page

6.

HOOK

LUBRICATION

TEST

AND

ADJUSTMENT

Thread machine, as instructed on

pages

7

and

8.

Sew

about

three

yards

of scrap material.

Remove

material.

Pay

no

attention

at

this

time

to

stitching quality or

amount

of oil spray.

Remove

bed

slide

E, Fig. 8.

Run

machine

for

approximately

one

minute to es

tablish a uniform

rate

of flow. Without stopping ma

chine, hold a piece of white

paper

underneath hook

for 15 seconds without moving

paper

during interval.

Remove

paper

and

inspect: There should be a

pat

tern of

three

sprays

(two light lines on

outside

and

one

heavier,

wider

line in centre)

as

shown

in Fig. 7.

If

there

is

no

trace

of

oil

or

an

excess

of

oil

on

test

paper

Remove

needle,

bobbin

and

bobbin

case

from

ma

chine.

Remove screw R

and

position

finger

S, Fig. 8. Loosen

two

screws

D

and

remove

sewing

hook

B, Fig. 8

from

hook driving shaft,

as

instructed on

page

20.

Loading...

Loading...