HOOK

LUBRICATION

(Cont'd)

Loosen

filter

screw

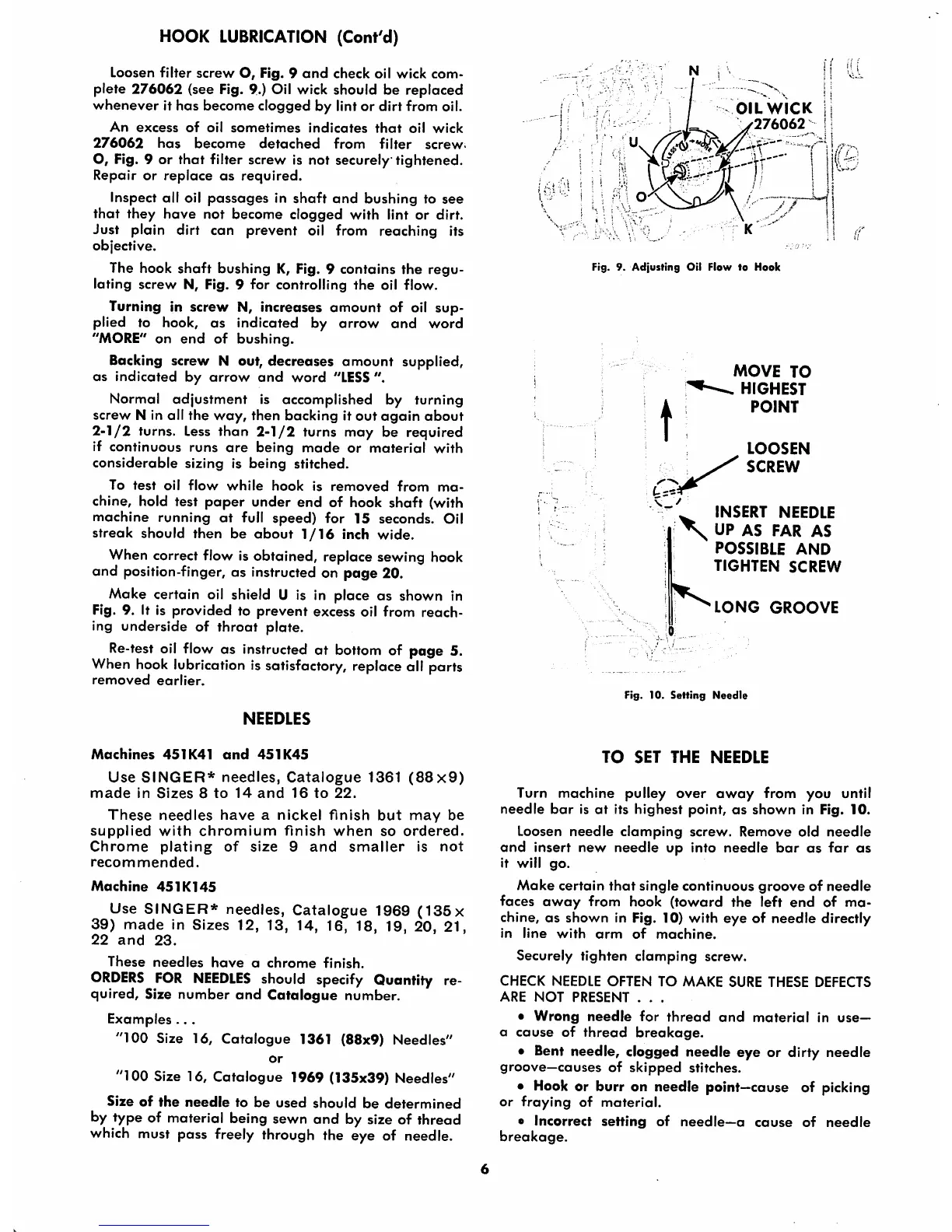

O, Fig. 9

and

check oil wick

com

plete 276062 (see Fig. 90 Oil wick should be replaced

whenever

it has become clogged by lint or dirt from oil.

An

excess

of

oil

sometimes

indicates

that

oil

wick

276062

has

become

detached

from

filter

screw.

O, Fig. 9 or

that

filter screw is not

securely

tightened.

Repair

or

replace

as

required.

Inspect

all

oil

passages

in

shaft

and

bushing

to

see

that

they

have

not

become

clogged

with

lint

or

dirt.

Just plain dirt can prevent oil from reaching its

objective.

The hook

shaft

bushing K, Fig. 9 contains

the

regu

lating

screw

N, Fig. 9 for controlling

the

oil flow.

Turning in screw N, increases

amount

of oil

sup

plied to hook,

OS

indicated by

arrow

and

word

"MORE" on

end

of

bushing.

Backing screw N out, decreases amount supplied,

OS

indicated

by

arrow

and

word

"LESS

".

Normal adjustment is accomplished by turning

screw

N in all

the

way,

then

backing

it

out

again

about

2-1/2

turns.

Less

than

2-1/2

turns may be required

if continuous runs

are

being

made

or

material

with

considerable

sizing is

being

stitched.

To

test

oil

flow

while

hook

is

removed

from

ma

chine, hold test

paper

under

end

of hook

shaft

(with

machine running

at

full speed) for 15 seconds. Oil

streak

should

then

be

about

1/16

inch

wide.

When correct flow is obtained, replace sewing hook

and position-finger, as instructed on page 20.

Moke certain oil shield U is in place as shown in

Fig. 9. It is provided to prevent excess oil from reach

ing

underside

of

throat

plate.

Re-test oil flow as instructed at bottom of page 5.

When hook lubrication is satisfactory, replace all parts

removed

earlier.

NEEDLES

Machines

451K41

and

451K45

LJse

SINGER*

needles,

Catalogue

1361

(88x9)

made

in

Sizes

8

to

14

and

16

to

22.

These

needles

have

a

nickel

finish

but

may

be

supplied

with

chromium

finish

when

so

ordered.

Chrome

plating

of

size

9

and

smaller

is

not

recommended.

Machine

451K145

Use

SINGER*

needles,

Catalogue

1969

(135x

39)

made

in Sizes 12, 13, 14, 16, 18, 19, 20, 21,

22

and

23.

These

needles

have

a

chrome

finish.

ORDERS

FOR

NEEDLES

should specify Quantity re

quired, Size number

and

Catalogue number.

Examples

..

.

"ICQ Size 16,

Catalogue

1361 (88x9)

Needles"

or

"100

Size 16,

Catalogue

1969 (135x39) Needles"

Size

of

the

needle

to

be

used

should

be

determined

by type of material being sewn and by size of thread

which

must pass freely through the eye of needle.

OILWICK

276062

• I 1

1"'^

Fig. 9.

Adjusting

Oil Flow to

Hook

t

MOVE

TO

.

HIGHEST

POINT

LOOSEN

SCREW

INSERT

NEEDLE

UP

AS

FAR

AS

POSSIBLE

AND

TIGHTEN

SCREW

LONG

GROOVE

Fig. 10.

Setting

Needle

TO

SET

THE

NEEDLE

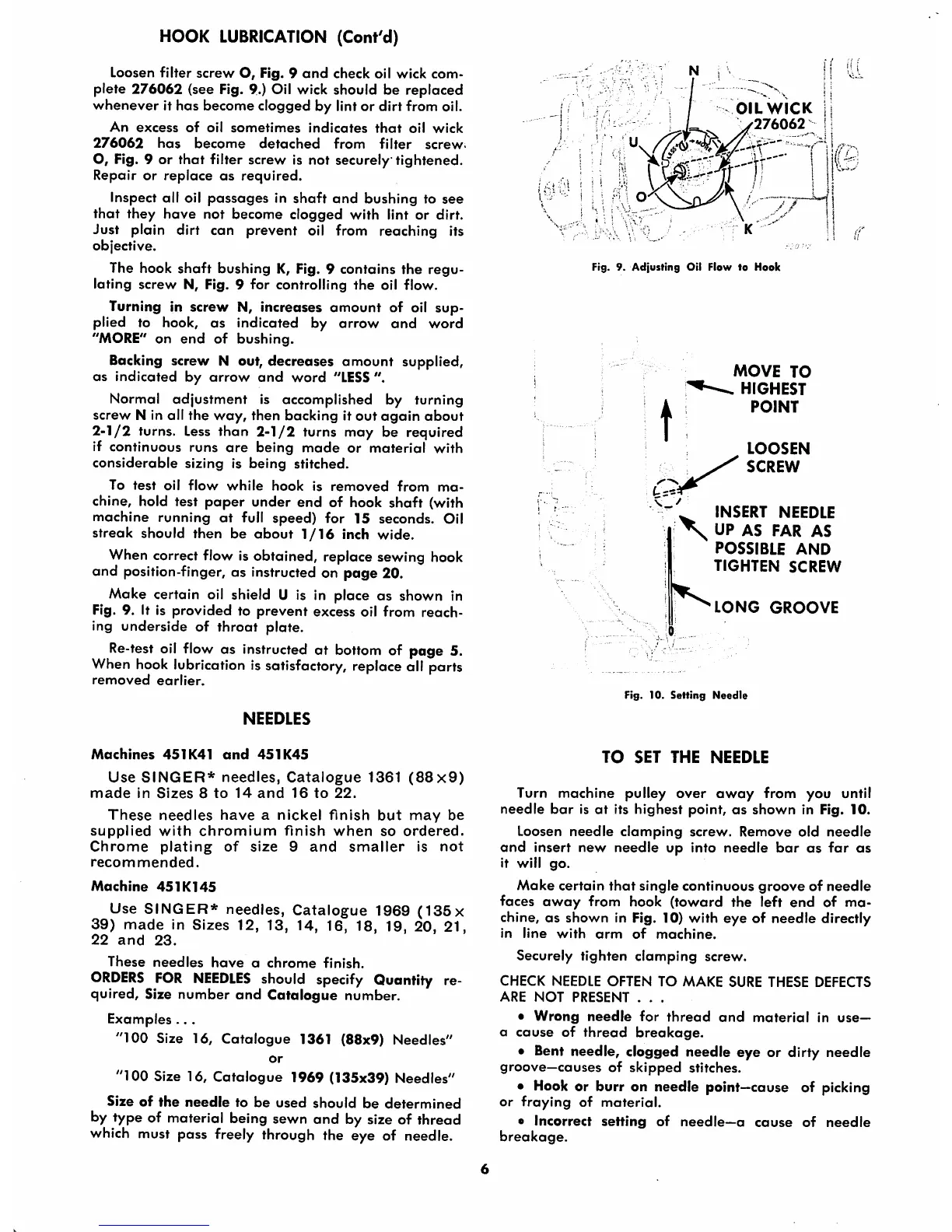

Turn machine pulley

over

away

from you until

needle

bar

is

at

its

highest

point,

as

shown

in Fig.

10.

Loosen

needle

clamping

screw.

Remove

old

needle

and

insert

new

needle

up into

needle

bar

as

far

as

it will

go.

Moke

certain

that

single

continuous

groove

of

needle

faces

away

from hook

(toward

the left

end

of ma

chine, as shown in Fig. 10) with eye of

needle

directly

in

line

with

arm

of

machine.

Securely

tighten

clamping

screw.

CHECK

NEEDLE

OFTEN

TO

MAKE

SURE

THESE

DEFECTS

ARE

NOT

PRESENT

. . .

•

Wrong

needle

for

thread

and

material

in use—

a

cause

of

thread

breakage.

• Bent needle, clogged needle

eye

or dirty needle

groove—causes

of

skipped

stitches.

• Hook or burr on needle point—cause of picking

or

fraying

of

material.

•

Incorrect

setting

of

needle—a

cause

of

needle

breakage.

Loading...

Loading...