TO

Time

the

feed

Feeding

movement

Is correctly timed, for

average

sewing conditions, by setting up

the

following

align

ment;

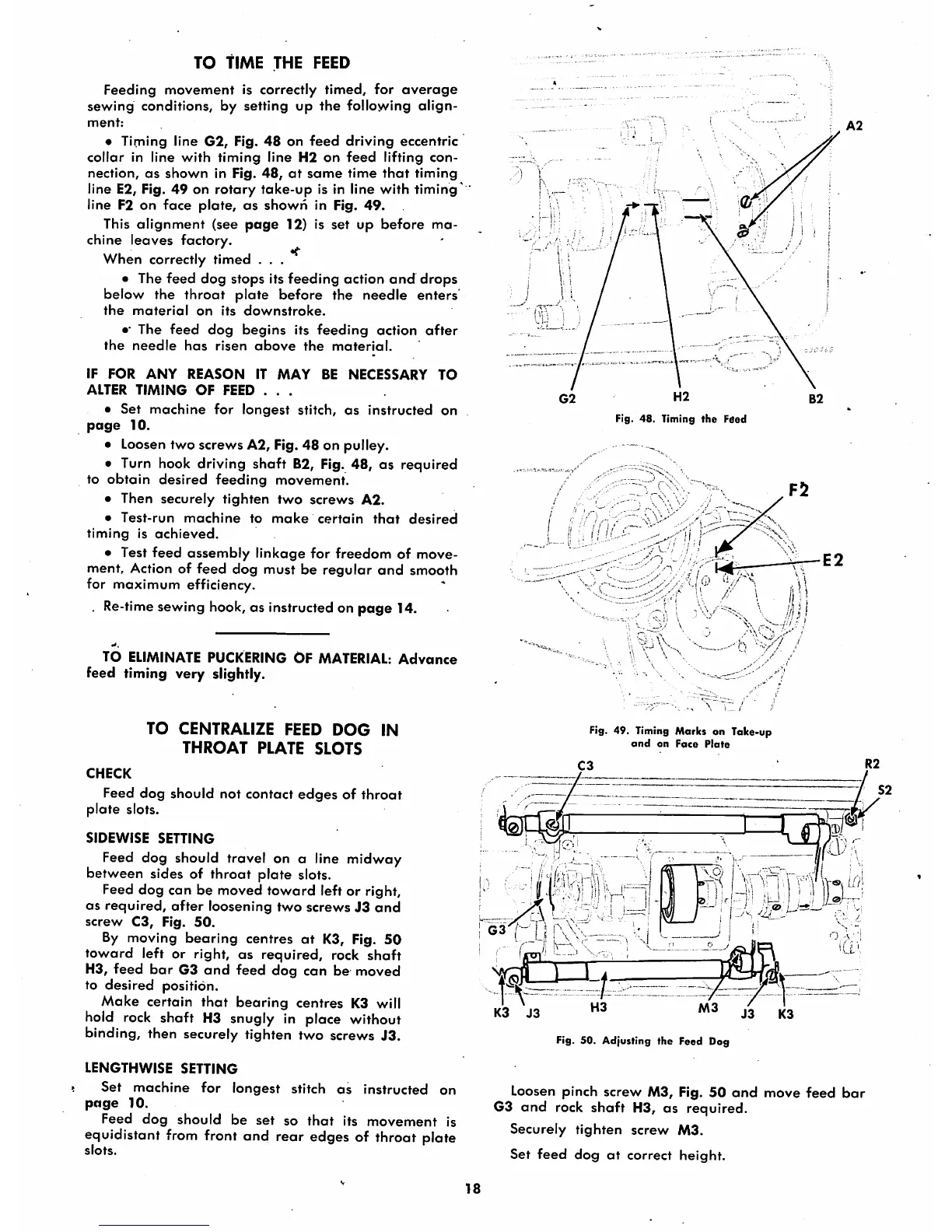

•

Timing

line

G2,

Fig.

48

on

feed

driving

eccentric

collar

in line

with

timing

line

H2

on

feed

lifting

con

nection,

OS

shown

in Fig.

48,

at

same

time

that

timing

line E2, Fig. 49 on rotary take-up is in line with

timing'

line F2 on

face

plate,

as

shown

in Fig.

49.

This

alignment

(see

page

12) is set up

before

ma

chine

leaves

factory.

When

correctly

timed

...

• The feed

dog

stops its

feeding

action

and

drops

below

the

throat

plate

before

the

needle

enters

the

material

on

its

downstroke.

•" The

feed

dog

begins

its

feeding

action

after

the

needle

has

risen

above

the

material.

IF

FOR

ANY

REASON

IT

MAY

BE

NECESSARY

TO

ALTER

TIMING

OF

FEED

...

•

Set

machine

for

longest

stitch,

as

instructed

on

page

10.

• Loosen

two

screws A2, Fig. 48 on pulley.

• Turn hook driving

shaft

B2, Fig. 48, as required

to

obtain

desired

feeding

movement.

• Then securely

tighten

two

screws A2.

•

Test-run

machine

to

make

certain

that

desired

timing

is

achieved.

• Test

feed

assembly

linkage

for

freedom

of move

ment, Action of

feed

dog

must

be

regular

and

smooth

for maximum efficiency.

. Re-timesewing hook, as instructed on

page

14.

TO ELIMINATE PUCKERING OF MATERIAL:

Advance

feed timing very slightly.

TO

CENTRALIZE FEED

DOG

IN

THROAT

PLATE

SLOTS

CHECK

Feed

dog

should not contact

edges

of

throat

plate

slots.

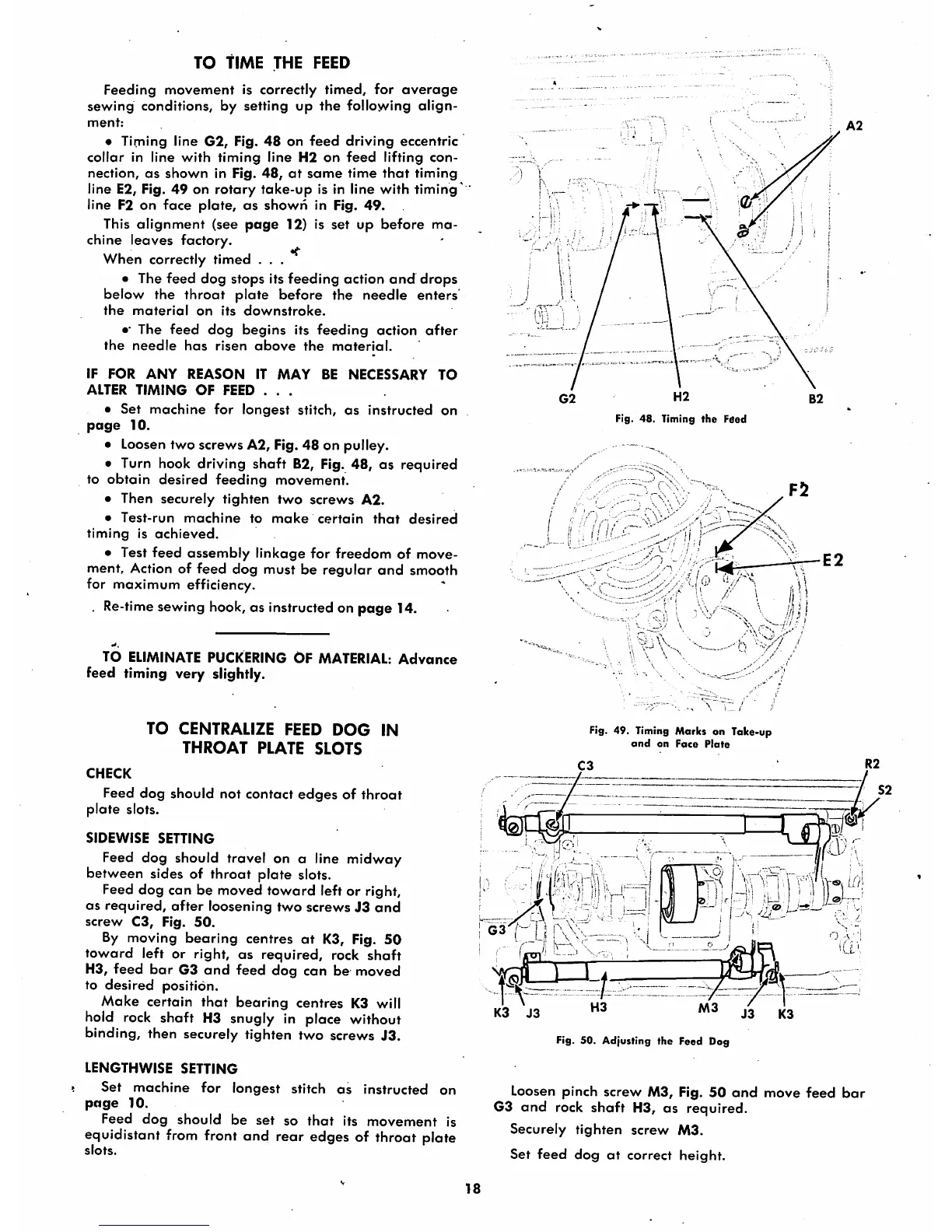

SIDEWISE

SETTING

Feed dog should travel on a line midway

between sides of throat plate slots.

Feed dog can be moved

toward

left or right,

OS

required,

after

loosening

two

screws

J3

and

screw

C3,

Fig.

50.

By moving

bearing

centres

at

K3, Fig.

50

toward

left or right,

as

required, rock

shaft

H3, feed

bar

G3

and

feed dog can be- moved

to

desired

position.

Moke certain

that

bearing centres

K3

will

hold rock shaft H3 snugly in place without

binding, then securely tighten two screws J3.

LENGTHWISE

SETTING

Set

machine

for

longest

stitch

as

instructed on

page

10.

Feed

dog

should

be

set

so

that

its

movement

is

equidistant from front and rear edges of throat plate

slots.

18

K3

J3

\

Fig.

48.

Timing

the

Ffied

I

,-r

•

".^1.

-.v

-'jC

V

//

'•\\v

;

Fig. 49.

Timing

Morks on Toke-up

and

on

Face

Plate

JO

Jut

^

i'\

hi

f'V\Y®ii/h

!lrL

-I

2U:1

^1

iB

I I

J3

K3

Fig. 50. Adjusting the Feed Dog

Loosen pinch

screw

M3, Fig.

50

and

move

feed

bar

G3

and

rock

shaft

H3, as required.

Securely

tighten

screw

M3.

Set

feed

dog

at

correct height.

Loading...

Loading...