Z3

P3

03

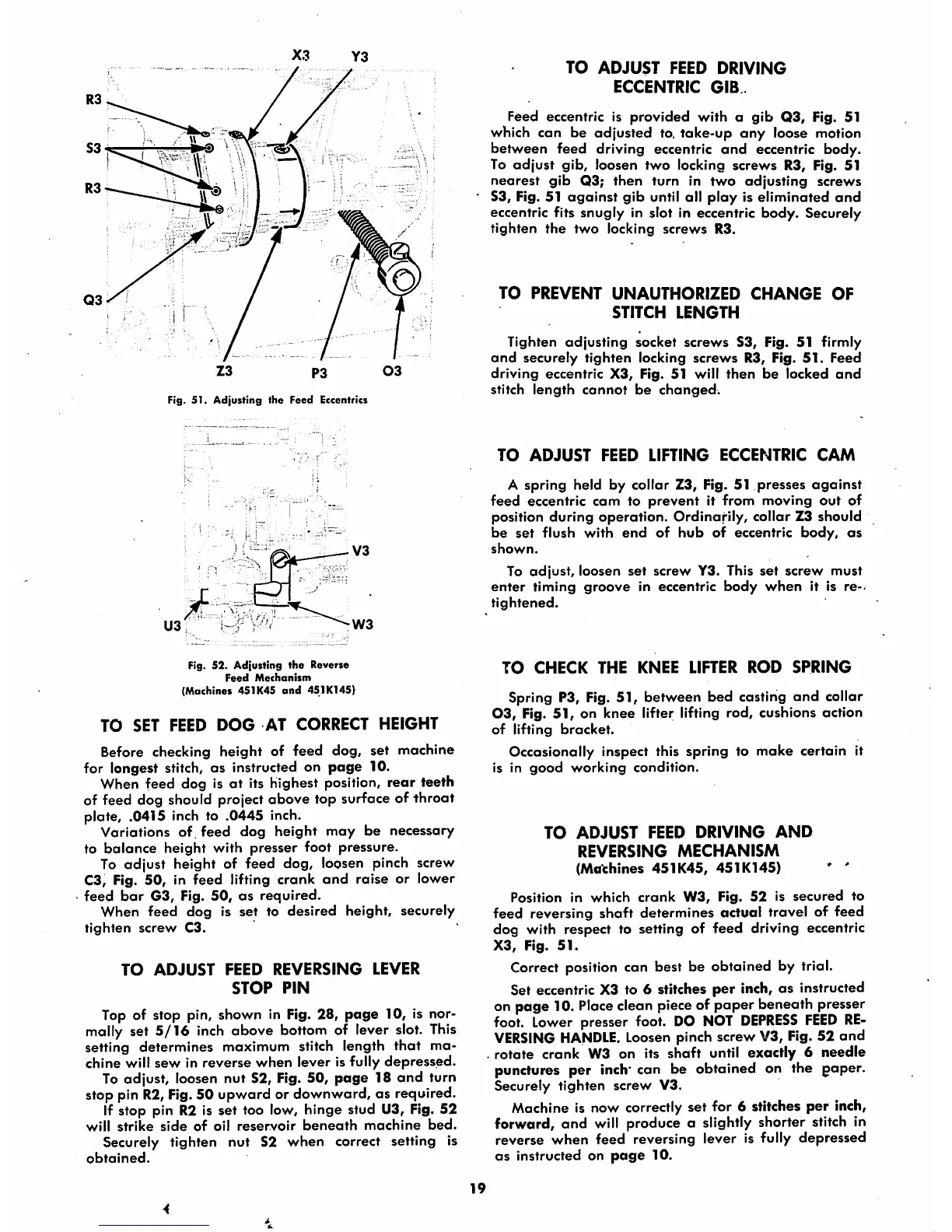

Fig. 51. Adjusting the Feed Eccentrics

U3

1

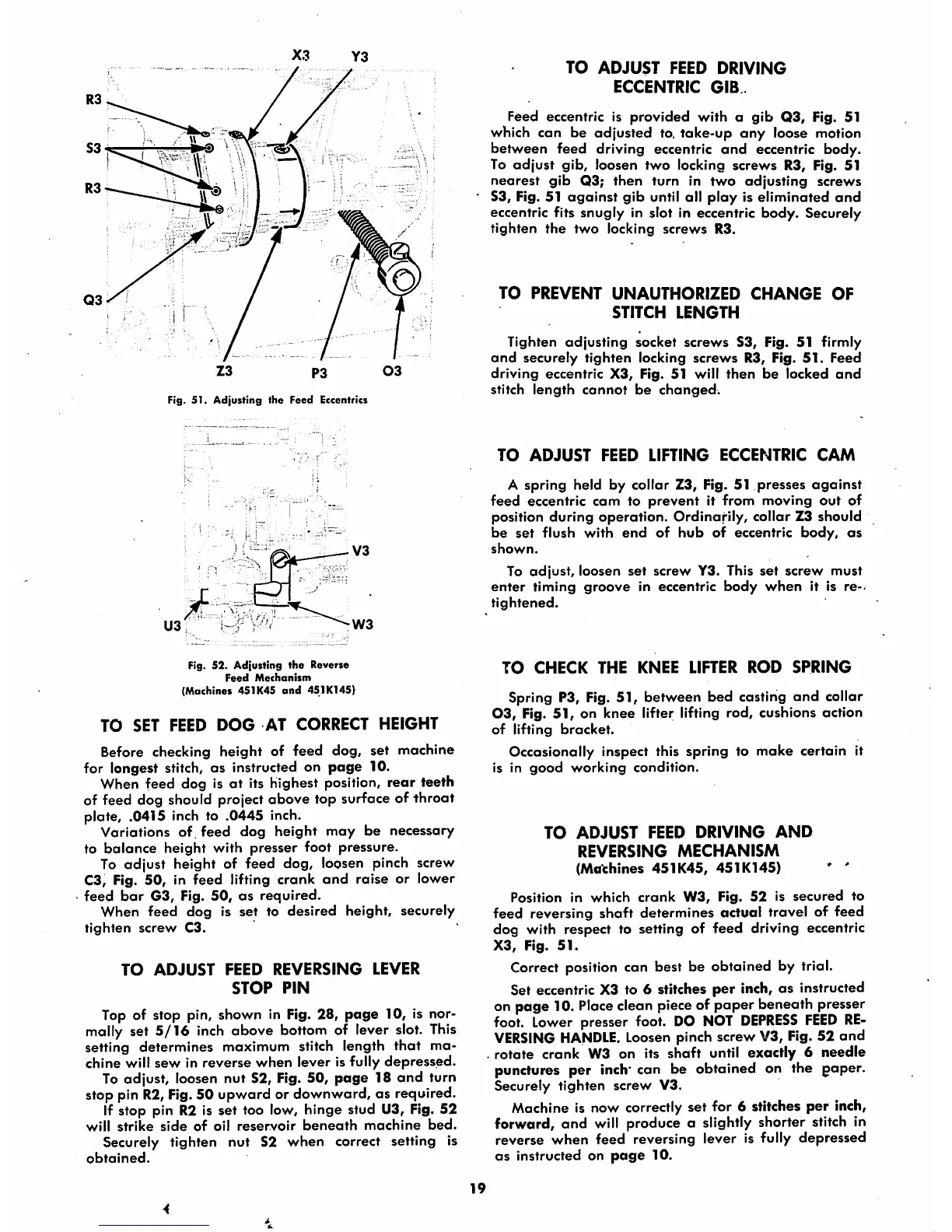

Fig. 52. Adjusting

the

Reverse

Feed

Mechanism

(Machines 451K45

and

451K145)

TO SET FEED

DOG

AT CORRECT HEIGHT

Before checking height of feed dog, set machine

for longest stitch,

as

instructed on

page

10.

When feed dog is

at

its highest position,

rear

teeth

of feed dog should project above top surface of throat

plate, .0415 inch to .0445 inch.

Variations

of

feed

dog

height

may

be

necessary

to

balance

height

with

presser

foot pressure.

To adjust height of feed dog, loosen pinch screw

C3, Fig. 50, in feed lifting crank

and

raise or lower

feed

bar

G3,

Fig.

50,

as

required.

When

feed

dog

is

set

to

desired

height, securely

tighten

screw

C3.

TO

ADJUST

FEED

REVERSING

LEVER

STOP

PIN

Top of stop pin, shown in Fig. 28,

page

10, is nor

mally set

5/16

inch above bottom of lever slot.

This

setting determines maximum stitch length

that

ma

chine will

sew

in reverse

when

lever is fully

depressed.

To adjust, loosen nut S2, Fig. 50,

page

18

and

turn

stop pin

R2,

Fig.50 upward or downward, as required.

If stop pin R2 is set too low, hinge stud U3, Fig. 52

will

strike

side

of

oil

reservoir

beneath

machine

bed.

Securely tighten

nut

S2

when

correct setting is

obtained.

TO

ADJUST

FEED

DRIVING

ECCENTRIC

GIB

Feed eccentric Is

provided

with

a

gib

Q3,

Fig. 51

which can be

adjusted

to.

take-up

any

loose motion

between feed driving eccentric

and

eccentric body.

To

adjust

gib,

loosen

two

locking screws R3, Fig. 51

nearest

gib

Q3;

then

turn in

two

adjusting

screws

S3, Fig. 51

against

gib

until all

ploy

is

eliminated

and

eccentric fits snugly in slot in eccentric body. Securely

tighten

the

two

locking

screws

R3.

TO

PREVENT

UNAUTHORIZED

CHANGE

OF

STITCH

LENGTH

Tighten

adjusting

socket

screws

S3, Fig. 51 firmly

and

securely

tighten

locking

screws

R3, Fig.

51.

Feed

driving

eccentric

X3, Fig. 51 will

then

be

locked

and

stitch

length

cannot

be

changed.

TO

ADJUST

FEED

LIFTING

ECCENTRIC

CAM

A

spring

held by collar Z3, Fig. 51

presses

against

feed

eccentric

cam

to

prevent

it

from

moving

out

of

position

during

operation.

Ordinarily,

collar Z3 should

be

set

flush with

end

of

hub

of eccentric body,

as

shown.

To

adjust,

loosen

set

screw

Y3. This

set

screw

must

enter

timing

groove

in

eccentric

body

when

it is

re-<

tightened.

TO

CHECK

THE

KNEE

LIFTER

ROD

SPRING

Spring P3, Fig. 51, between bed casting

and

collar

03,

Fig.

51,

on

knee

lifter lifting rod, cushions action

of

lifting

bracket.

Occasionally inspect this spring to moke certain it

is in

good

working

condition.

TO

ADJUST

FEED

DRIVING

AND

REVERSING

MECHANISM

(Machines

451K45,

451K145)

' '

Position in

which

crank

W3,

Fig.

52

is

secured

to

feed reversing

shaft

determines actual travel of

feed

dog with respect to setting of

feed

driving eccentric

X3,

Fig.

51.

Correct position can best be obtained by trial.

Set eccentric X3 to 6 stitches per inch, as instructed

on page 10.

Place

clean pieceof paper beneath presser

foot.

Lower

presser foot.

DO

NOT

DEPRESS

FEED

RE

VERSING

HANDLE.

Loosen

pinch screw V3, Fig. 52 and

rotate crank W3 on its

shaft

until exactly 6 needle

punctures per inch' can be obtained on the paper.

Securely

tighten

screw

V3.

Machine is now correctly set for 6 stitches

per

inch,

forward, and will produce a slightly shorter stitch in

reverse

when

feed

reversing lever is fully

depressed

as

instructed on

page

10.

19

Loading...

Loading...