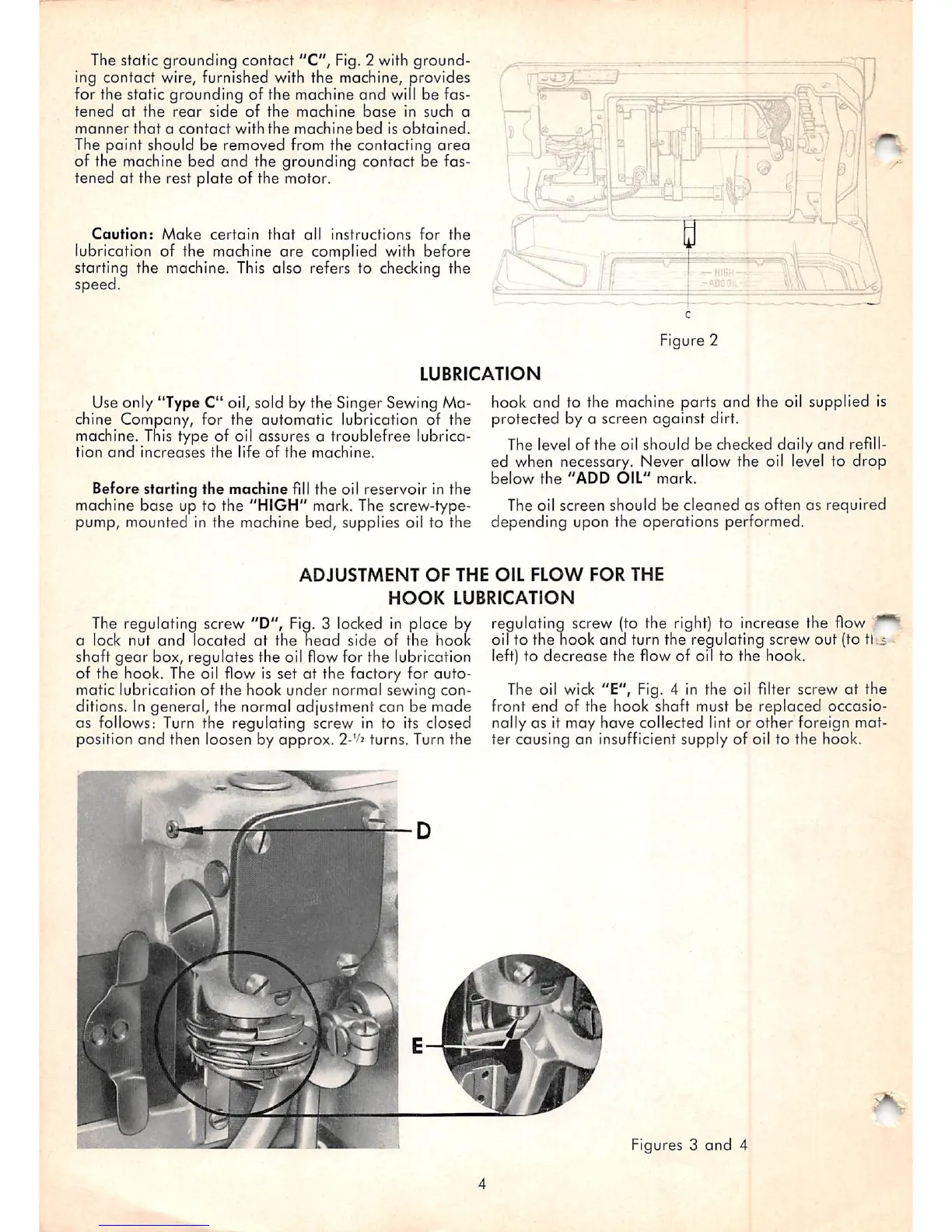

The static grounding contact

"C",

Fig. 2 with

ground

ing contact wire, furnished with the machine, provides

for the static grounding of the machine

and

will be fas

tened

at

the

rear

side

of

the

machine

base

in

such

a

manner

that

a

contact

with

the

machinebed

is

obtained.

The

paint

should be removed from the contacting

area

of the machine bed

and

the grounding contact be fas

tened at the rest plate of the motor.

Caution:

Make

certain

that

all

instructions

for

the

lubrication of the machine are complied with before

starting the machine. This also refers to checking the

speed.

0

Figure 2

LUBRICATION

Use only "Type C" oil, sold by the Singer Sewing Ma

chine

Company,

for

the

automatic

lubrication

of

the

machine. Tnis type of oil assures a troublefree lubrica

tion

and

increases

the

life

of

the

machine.

Before starting the machine

fill

the oil reservoir in the

machine base up to the "HIGH" mark. The screw-type-

pump, mounted in the machine bed, supplies oil to the

hook and to the machine parts and the oil supplied is

protected by a screen against dirt.

The level of the oil should be checked daily

and

refill

ed when necessary. Never allow the oil level to drop

below

the

"ADD

OIL"

mark.

The oil screen should be cleaned as often as required

depending upon the operations performed.

ADJUSTMENT

OF

THE

OIL

FLOW

FOR

THE

HOOK

LUBRICATION

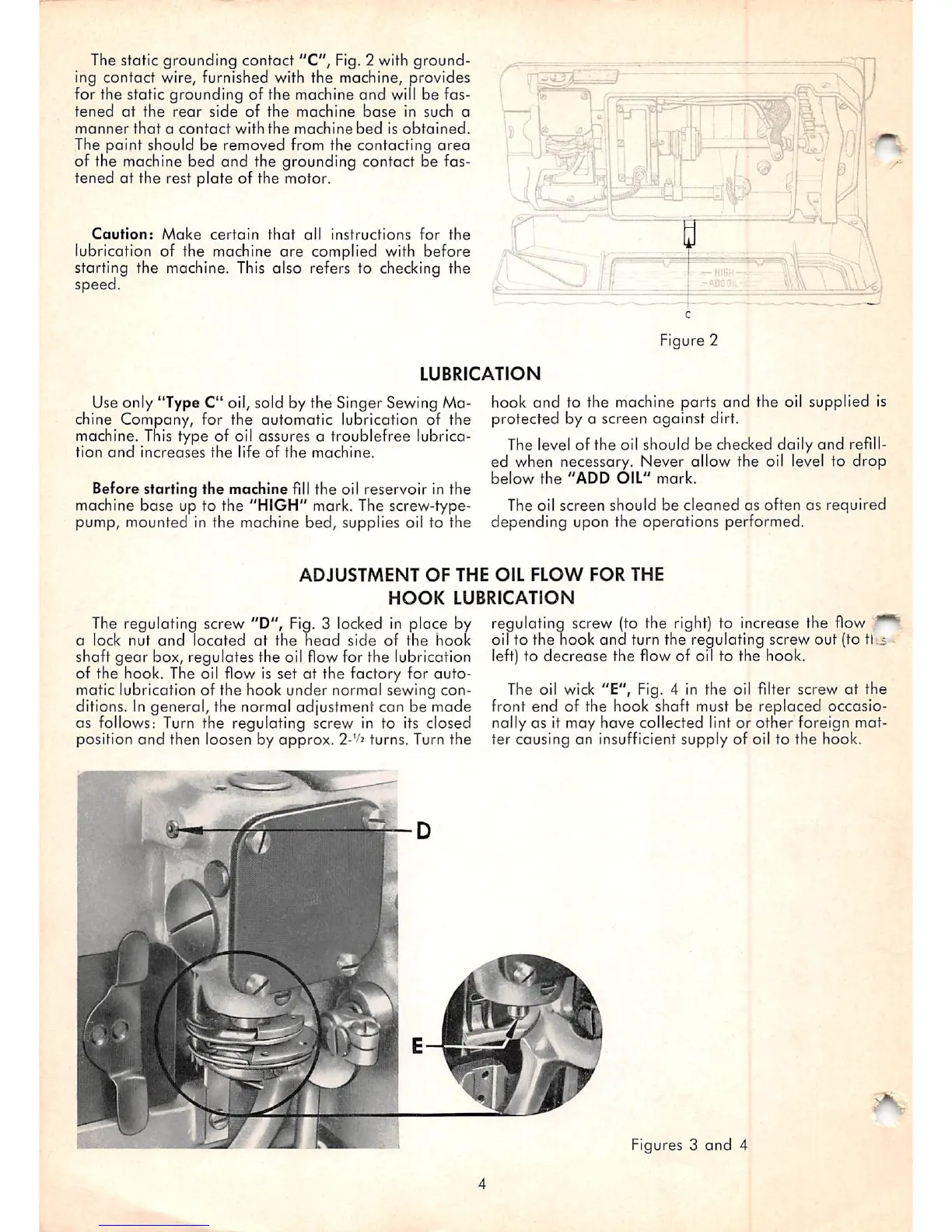

The regulating screw "D", Fig. 3 locked in place by

a

lock

nut

and

located

at

the

head

side

of

the

hook

shaft

gear

box, regulates the oil flow for the lubrication

of the

hook.

The

oil

flow

is

set at the

factory

for auto

matic lubrication of the hook under normal sewing con

ditions. In general, the normal adjustment can be made

as follows: Turn the regulating screw in to its closed

position

and

then loosen by approx.

2-^^^

turns. Turn the

regulating screw (to the

right)

to increase the

flow

•*"

oil to the

hook

and

turn the regulating screw out (to tl.^

left)

to decrease the flow of oil to the hook.

The oil wick "E", Fig. 4 in the oil filter screw at the

front end of the hook shaft must be replaced occasio

nally as it may have collected lint or other foreign mat

ter causing an insufficient supply of oil to the hook.

Figures 3

and

4

Loading...

Loading...