24

OPERATING INSTRUCTIONS….cont

Upper guide:

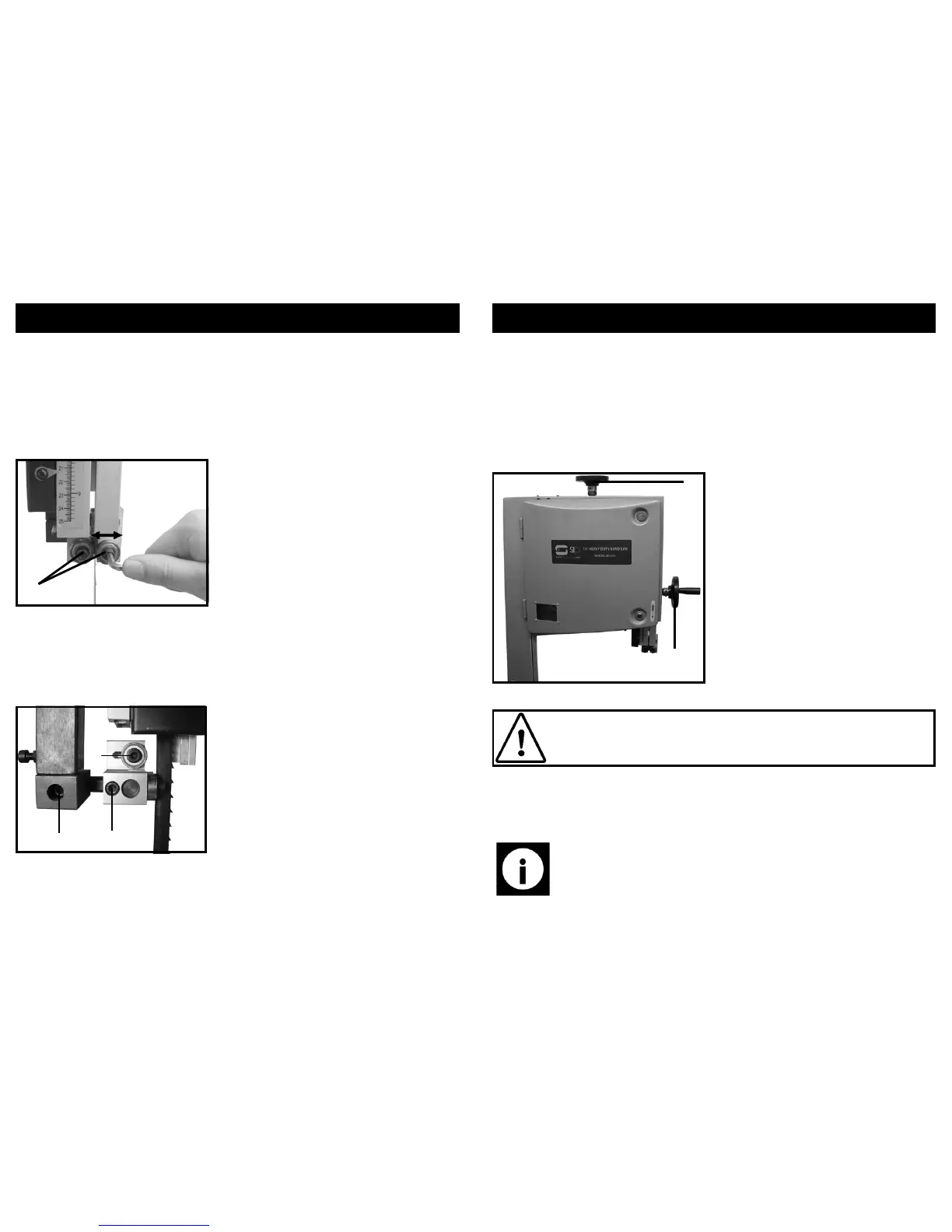

The lateral support bearings should be set so that they are approximately 0.5 mm

away from the blade.

• Loosen (no need to remove) the bearing support screws (A).

• Slide the bearing assembly left / right until it is in the correct position.

• Re-tighten the bearing support screws.

A

The rear thrust bearings should be set so that they are approximately 3 mm behind the

blade. They will only come into contact with the blade as the work-piece is being cut.

Due to the many different sizes of band-saw blades available, the rear support bearing

needs to have extra movement compared to the lateral support bearings. This is

achieved by having 3 different points of movement as opposed to 1 on the lateral sup-

port bearings.

A B

C

• Loosen the required allen bolt/s.

• Move the bearing, bearing assembly and/or the pole until the bearing is set in

the correct position.

• Re-tighten all of the allen bolts to secure the bearing in place.

Allen bolt A - This allows the bearing assembly

support pole to be moved and should be utilised

when large movement is required.

Allen bolt B - This allows the bearing support

assembly to be moved on the pole.

Allen bolt C - This allows the bearing to move

along the channel on the bearing support as-

sembly and should be utilised when only a small

amount of movement is required.

17

ASSEMBLY INSTRUCTIONS….cont

This machine is supplied partly assembled, Prior to use, the following items need to be

fitted to the band saw:

• The bearing guide hand-wheel

• The blade tension hand-wheel

• The main table

• The rip-fence guide rail

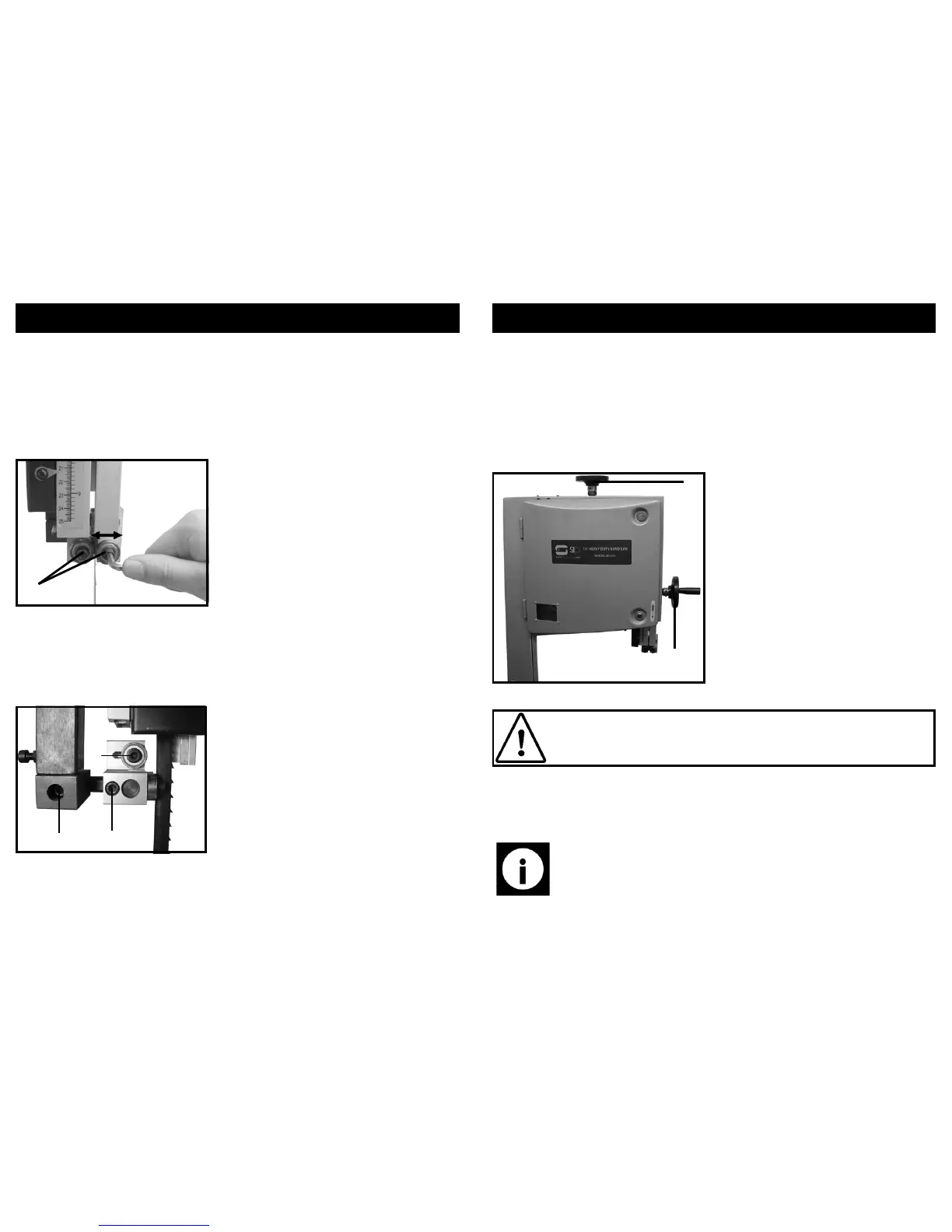

Fitting the blade tension and bearing guide hand wheel’s (A and B):

• Fit the table onto the table trunnion (C) ensuring that the 4 holes on the trun-

niun line up with the threaded holes on the bottom of the main table.

• Fit 4 x M8 x 16 mm securing bolts (D) and hand tighten to secure.

A

B

• Fit the blade tension hand wheel (A)

onto the thread rod, gravity will hold

it in place.

• Fit the bearing guide hand wheel (B)

onto the shaft of the worm gear.

• Secure with the supplied grub screw.

Note: The bolts only need to be hand tightened at this point as some ad-

justment may be necessary to set the table correctly.

Fitting the table:

Caution: Due to the weight of the main saw bed and other factors, this

operation would ideally be carried out by at least 2 persons to reduce the

risk of personal injury and / or damage to the machine.

Loading...

Loading...