16

OPERATING INSTRUCTIONS

There are no hard and fast rules by which a particular gauge of electrode is selected,

usually this is determined by the type of welding required and the thickness of the

workpiece e.g. a butt weld in 1.5mm (1/16”) sheet metal can be done by a 1.6mm or

2.0mm electrode, the difference being that the 2.0mm electrode will do the job

more quickly.

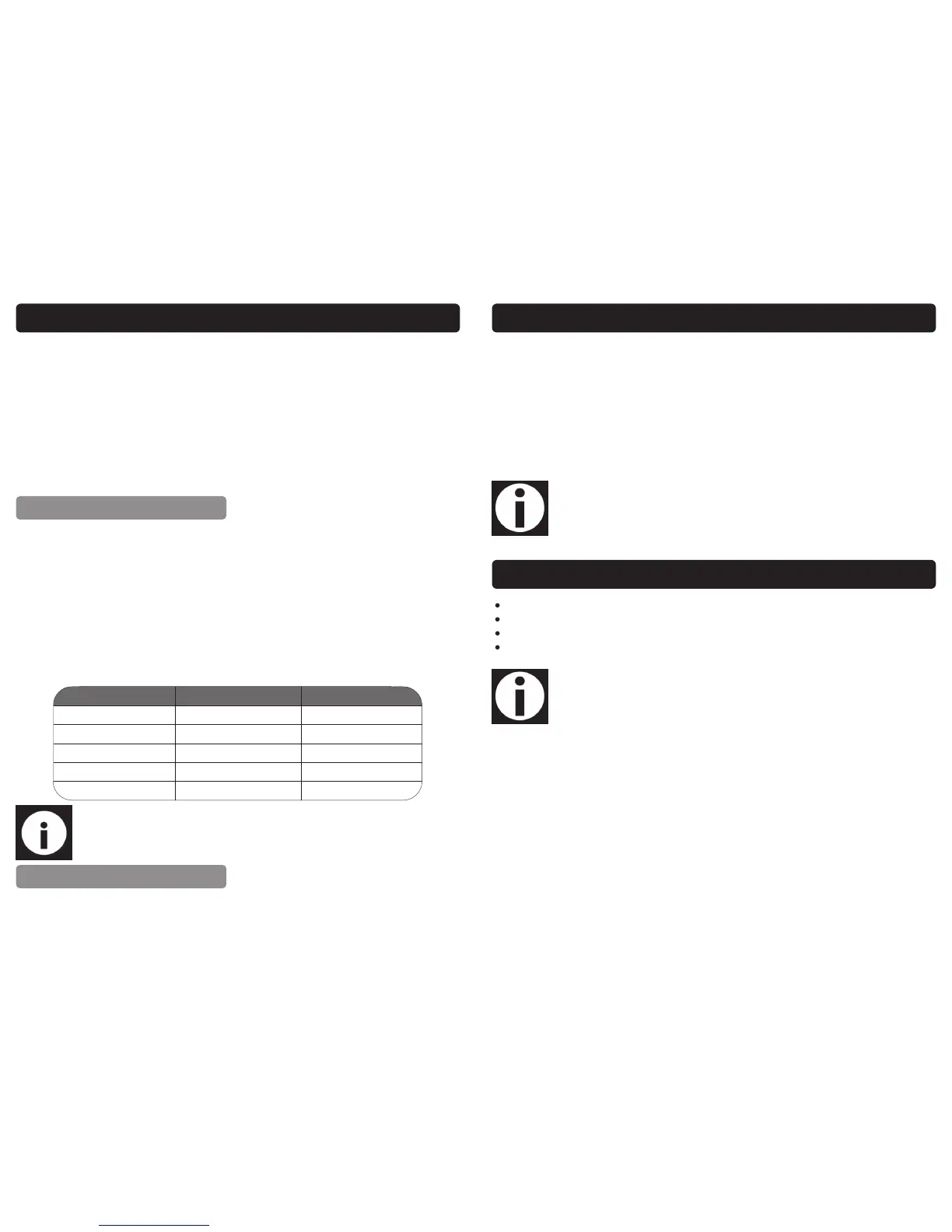

The table below gives a guide as to which electrode is most suitable according to the

material thickness. This table is only a guide, and values given are a indication only.

These welding current values are for the E6013 electrodes, for other types of electrode

consult their data sheet.

Note: The above is a guide only; always try a short weld test at the setting

selected. It is normal to make minor adjustments to achieve the required

weld.

The welder should be set to a specific amperage to match the electrode size (see

above table).

ARC WELDING

AMPERAGE CONTROL

Electrode Size mm Material Thickness mm Welding Current (A)

1.6 1 - 1.6 25 - 40

2.0 1.6 - 2.6 40 - 70

2.5 2.6 - 4.0 60 - 100

3.25 3.0 - 5.0 80 - 130

4.0 5.0 - 7.0 130 - 170

Important information: These units can be set to deliver different output currents at a

duty cycle that is written as a percentage on page 14. This percentage represents the

welding time in a 10 minute cycle, e.g. 60% means that the welding time is 6 minutes

and the rest time is 4 minutes. If a unit is used beyond its duty cycle the temperatures

of some components might become too high due to over use; The internal thermal

protector will then prevent the unit from operating. Its Intervention is Indicated by the

alarm light on the front panel, If this happens leave the machine switched on with the

fan running and allow It to cool down. The thermal protector will re-set automatically

after a short period of time when the components have cooled you will be able to

restart welding.

13

These SIP Inverter welders are covered by a 12 month parts and labour warranty cov-

ering failure due to manufacturers defects. This does not cover failure due to misuse or

operating the inverter welder outside the scope of this manual - any claims deemed

to be outside the scope of the warranty may be subject to charges Including, but not

limited to parts, labour and carriage costs, failure to regularly clean your inverter weld-

er will shorten its working life and reduce performance.

The warranty does not cover consumable items such as electrode holders & clamps,

etc.

GUARANTEE

Note: Proof of purchase will be required before any warranty can be hon-

oured.

CONTENTS AND ACCESSORIES

Note: If any of the above are missing or damaged, contact your distributor

immediately.

Inverter Welder.

Instruction Manual.

2m Welding Cable with Electrode Holder.

2m Earth Cable with Earth Clamp.

Loading...

Loading...