5

SKF LAGD 400

1. Application

The SKF MultiPoint Automatic Lubricator LAGD 400 is an eight-point lubrication system.

The lubricator can be used with all standard SKF grease types and produces a maximum

pressure of 40 bar (600 psi). The maximum pressure is guaranteed when the total length

of the lubrication tubes does not exceed 5 metres (16 ft).

2. Description

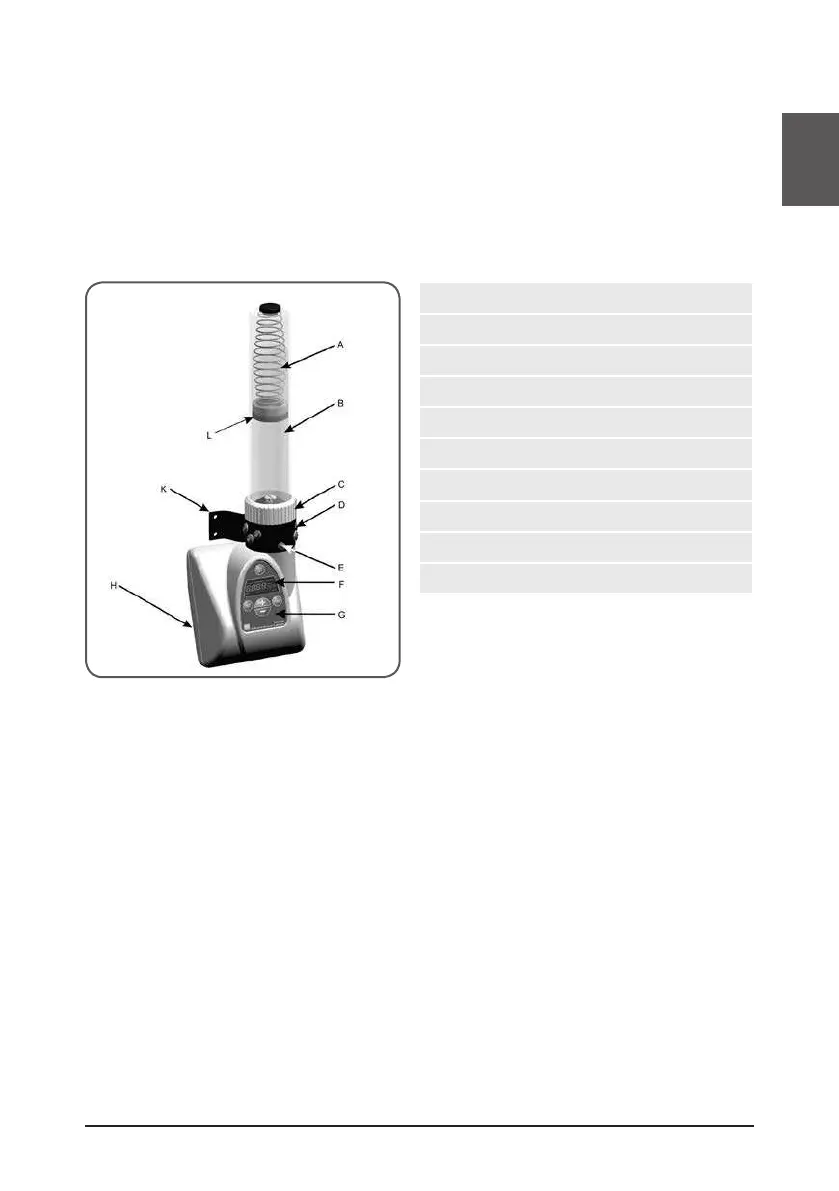

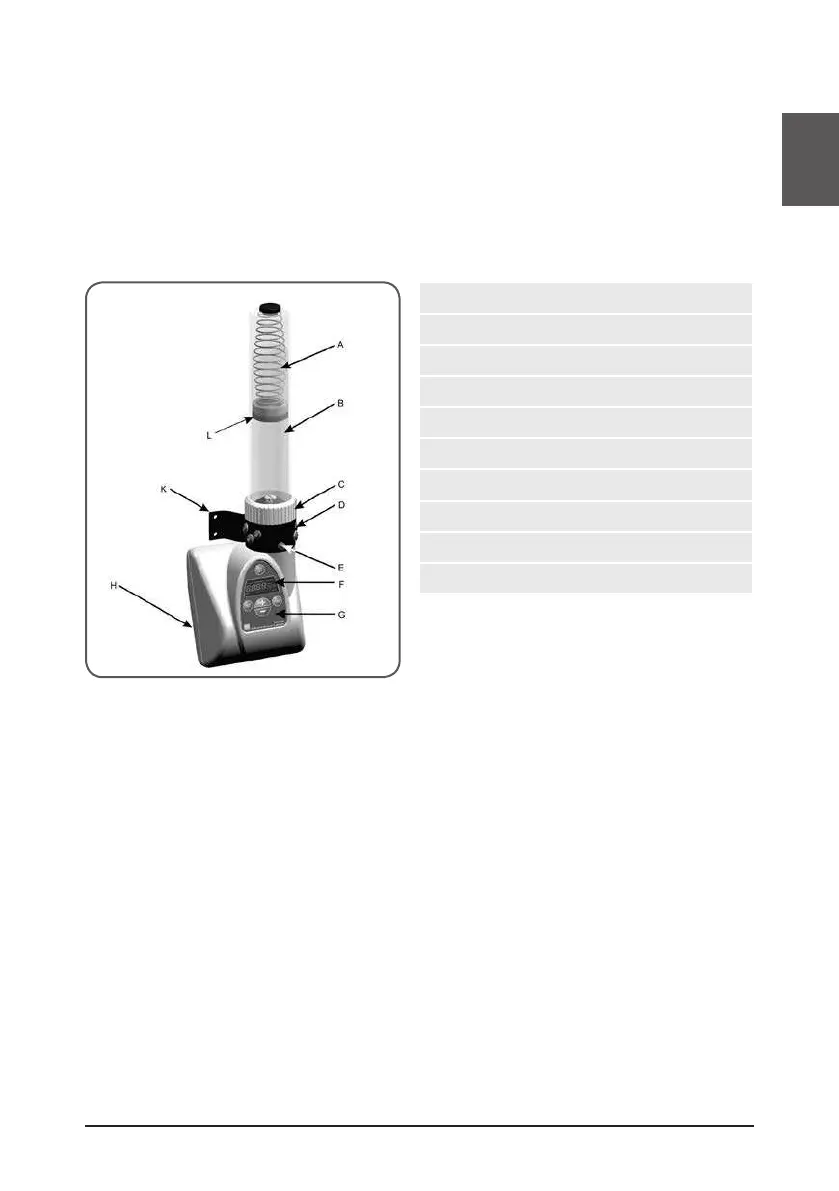

2.1 Identification of parts

A feed spring

B cartridge protection cover

C locking ring

D grease outlets (numbered 1 to 8)

E grease fitting nipple

F display

G control panel

H power and alarm connectors

K mounting bracket

L follower plate

Figure 1

2.2 Method of operation

During each cycle, an electric motor in the lubricator pre-loads a piston. The piston draws

grease into a cylinder. The piston is released at the end of each cycle and pushes the

grease from the cylinder into the eight channels of the outlet block. The piston dispenses

the same quantity of grease through each channel.

The electric motor is controlled by a microprocessor. The microprocessor controls the

dispense modes and detects blocked lubrication tubes and empty grease cartridges.

2.3 Grease supply

A standard SKF grease cartridge supplies grease to the lubricator. An empty SKF grease

cartridge can be refilled through the grease filling nipple.

English

Loading...

Loading...