SKYJACK, Page 28 SJIII Compacts & Conventionals

February 2008

Section 2 - Operation Visual and Daily Maintenance Inspections

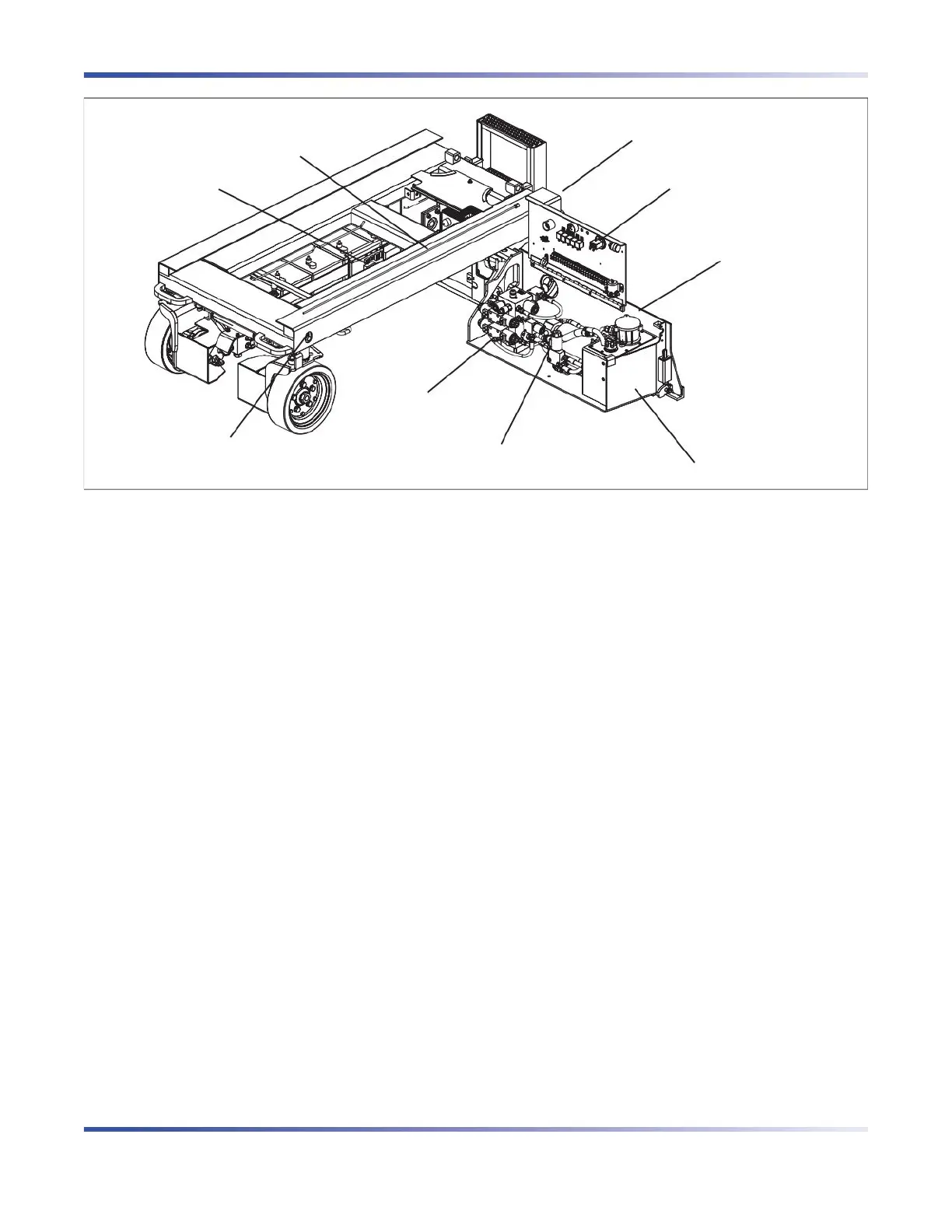

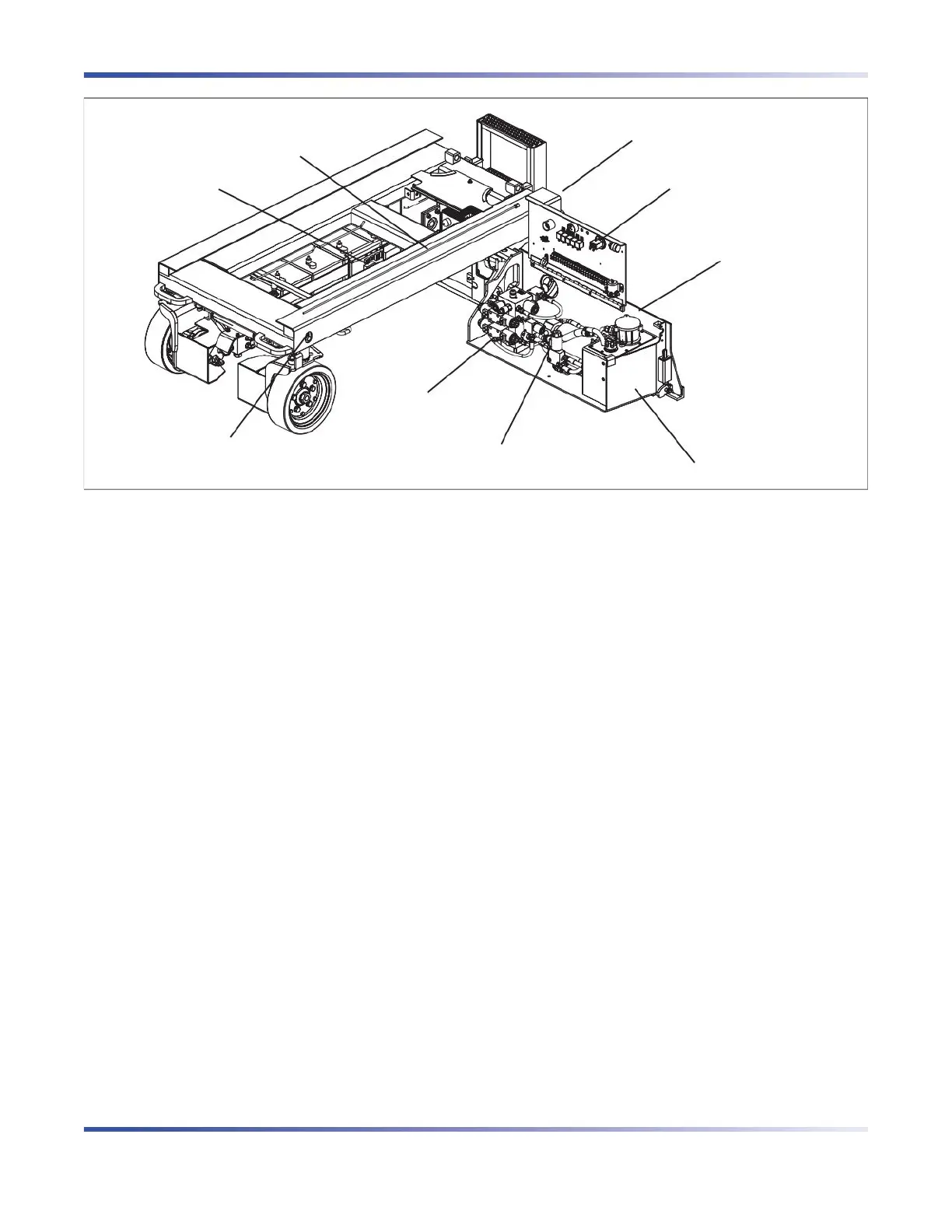

2.8-7 Hydraulic/Electric Tray Side

Ensure tray latch is secure and in proper -

working order.

Pothole Protection Device•

Ensure mechanisms have no sign of -

visible damage and are free from dirt and

obstructions.

Hydraulic Tank •

Ensure hydraulic filler cap is secure. -

Ensure tank shows no visible damage -

and no evidence of hydraulic leakage.

Hydraulic Oil•

Ensure platform is fully lowered, and then -

visually inspect the sight gauge located

on the side of the hydraulic oil tank.

The hydraulic oil level should be at or -

slightly above the top mark of the sight

glass.

Hydraulic Pump and Motor •

Ensure there are no loose or missing -

parts and there is no visible damage.

Electrical Panel •

Ensure panel is properly secured and -

there is no visible damage.

Ensure there are no loose wires or -

missing fasteners.

Proportional and Main Manifolds•

Ensure all fittings and hoses are properly -

tightened and there is no evidence of

hydraulic leakage.

Ensure there are no loose wires or -

missing fasteners.

Load/Tilt Sensor •

Ensure load/tilt sensor is properly secure -

and there is no visible damage.

Emergency Lowering Access Rod •

(If Equipped)

Ensure rod is properly secured and there -

is no visible damage.

Hydraulic Tank

Hydraulic Pump and

Motor

Electrical Panel

Main Manifold

Load/Tilt

Sensor

Hydraulic/Electric

Tray

Emergency Lowering

Access Rod

Compact

Greasing Point

Greasing Point

Loading...

Loading...