14

5693

21 2023

-

SE60/185 s2

MC_0258

Gear Leg & Motor Bracket Installation

! Please refer to the graphic for special considerations relating to your model !

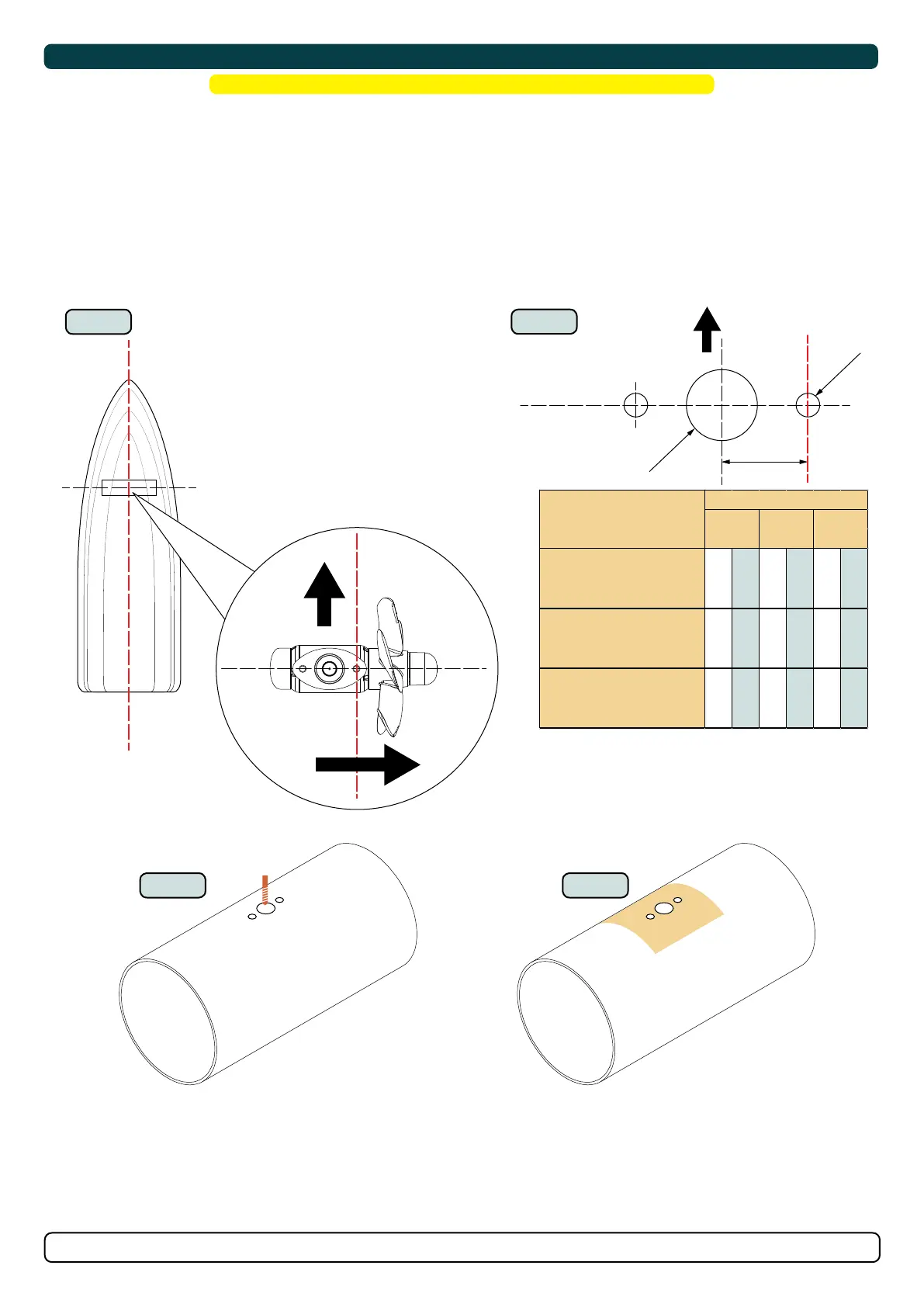

1. Mark the tunnel centreline and the boat’s centreline. (NB: Install the gear leg and propeller as shown for the thrust direction to correspond with

the control panel.)

2. Use the gasket or template (recommended) to mark the hole centres and double-check the measurements. One hole MUST be placed using

the boat centreline as shown above. (NB: All holes must be in-line with the tunnels’ centreline for correct installation, clearance between the

propeller and the tunnel is minimal.)

3. Drill the main centre hole followed by the two screw-holes.

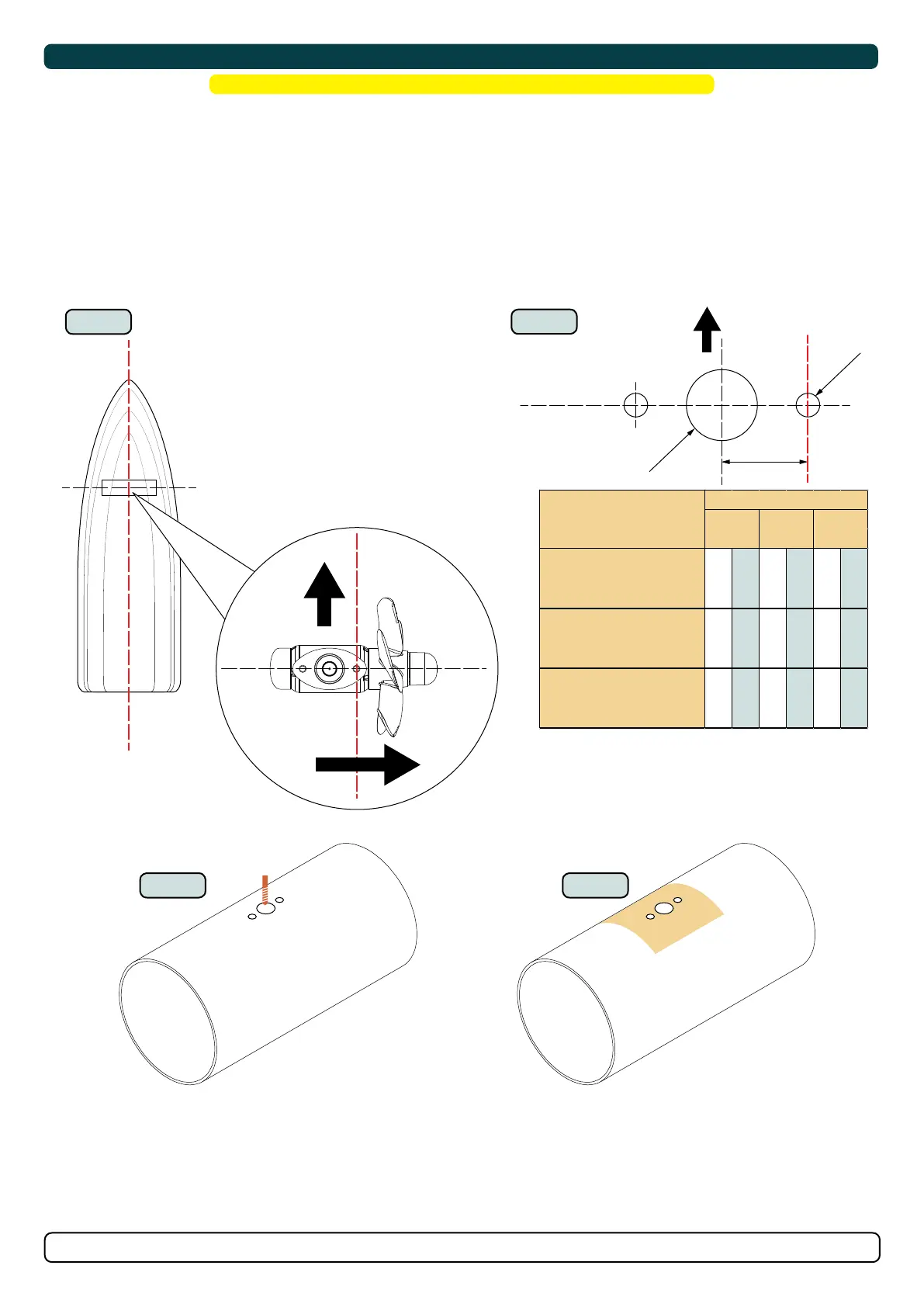

4. Smooth the surface of the tunnel. A rough surface will cause possible failure/ movement of the gear leg. The motor bracket must rest steadily on

the tunnel.

MG_0616

Gasket

Gear leg

Test the propeller turns without

obstruction with tunnel wall

Motor

bracket

Bolt plate

7

Gasket

Bolt plate

Bracket

BOW

5

6

BOW

Bolt plate

MIN

MAX

Measure the drive shaft has come through the motor

bracket at the correct height with the template supplied.

The template must sit on the

bracket surface with the bolt

plate within the measurement

cutout

MIN

MAX

MG_0612

Tunnel

centre line

Tunnel

centre line

Drill centre hole first

Smooth surface area

Boats

centre line

Boats

centre line

Bow

Stern

B

ØC

ØA

BOW

1

2

STARBOARD

BOW

3 4

mm inch mm inch mm inch

SE20/110S

SE25/110S

28 1,1 20 0,8 7 0,3

SE/SEP/SE IP/SEP IP 30/125S2

SE/SEP/SE IP/SEP IP 40/125S2

28 1,1 21 0,8 8,5 0,3

SE/SEP/SE IP/SEP IP 30/140S

SE/SEP/SE IP/SEP IP 40/140S

SE/SEP/SE IP/SEP IP 50/140S

SE/SEP/SE IP/SEP IP 60/185S2

29 11 23 0,9 8,5 0,3

Models

Measurements

Loading...

Loading...