17

5693

21 2023

-

SE60/185 s2

MG_0028

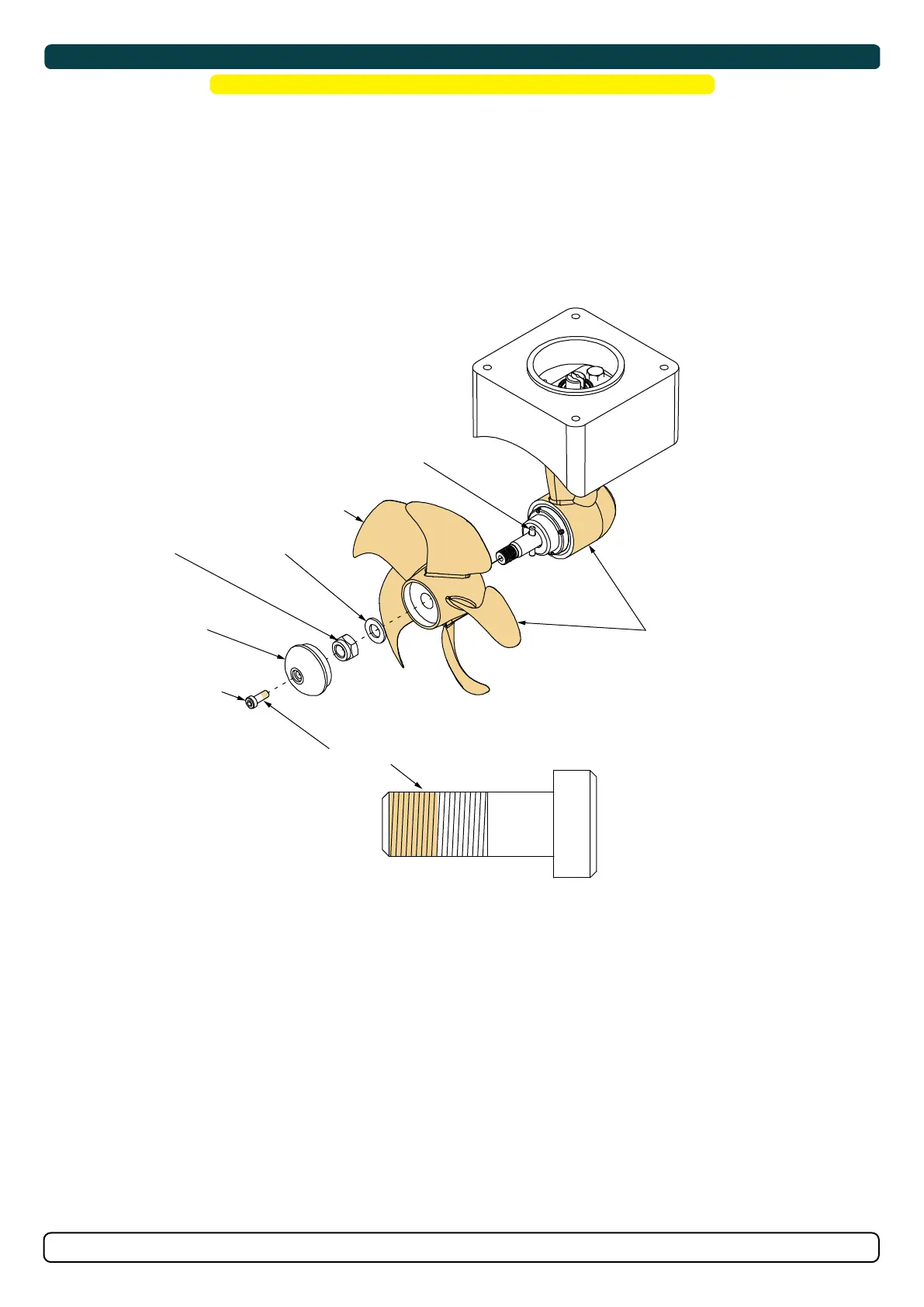

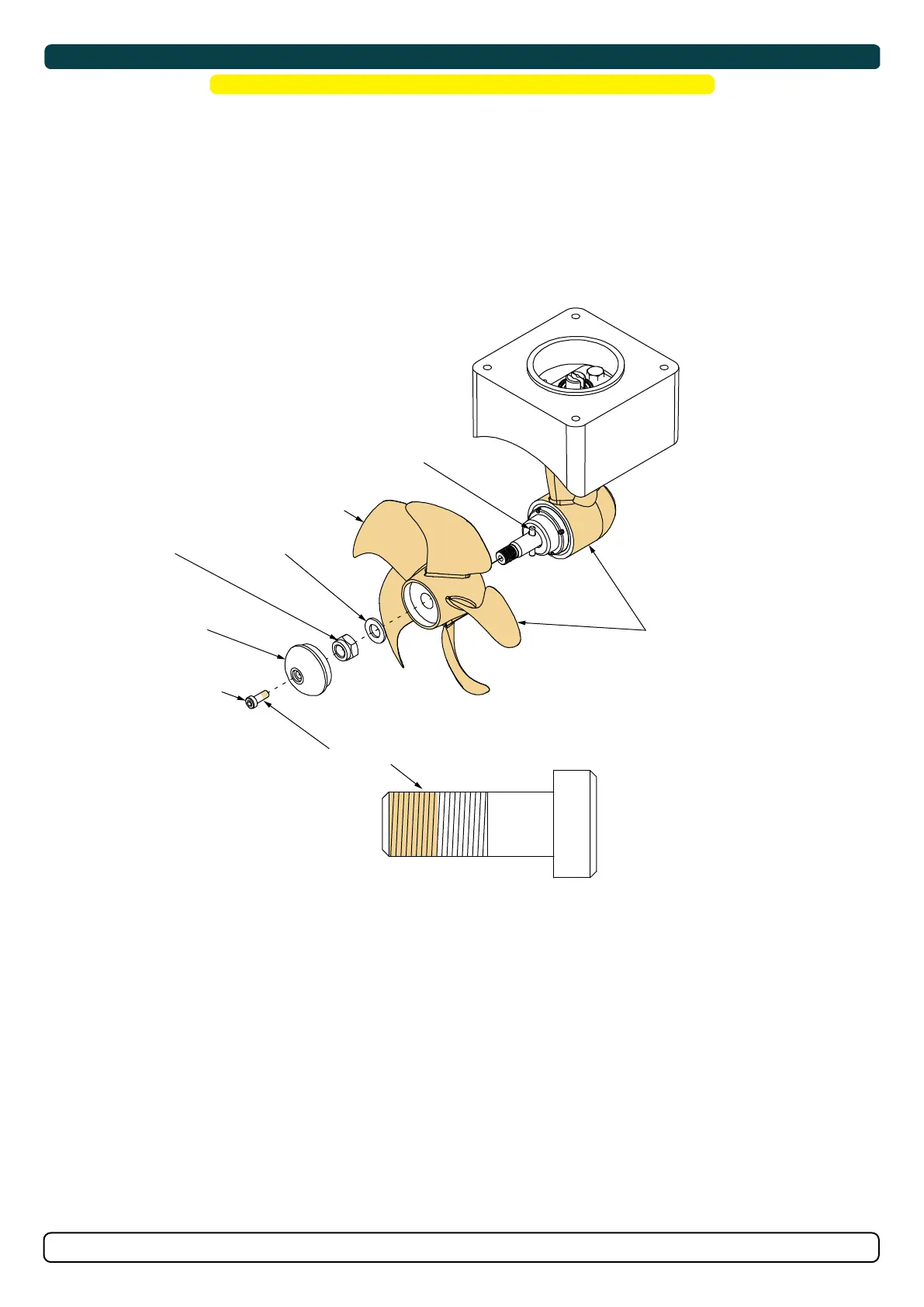

Anode holding screw

Apply Loctite 243 or similar

Anode

Lock nut

FASTEN

65 Nm

47.94 lb/ft

Washer

Propeller

Drive pin

Anti-fouling

Propeller Installation

MC_0018

! Please refer to the graphic for special considerations relating to your model !

1. Centre the drive pin and Insert the propeller onto the shaft spine. Rotate the propeller until the drive pin aligns with the internal slot in the

propeller.

2. Insert the washer to the end of the shaft spline. Tighten with the propeller lock-nut.

3. Insert the anode to the end of the propeller and tighten the anode holding screw. Apply a thread glue (Loctite 243 or similar) to ensure that the

anode holding screw does not unscrew itself from during the rotation of the propeller.

4. Apply anti-fouling to the gear leg and propeller. Do not apply anti-fouling to any rubber elements of the gear leg or anodes.

MC_0258

Gear Leg & Motor Bracket Installation

! Please refer to the graphic for special considerations relating to your model !

8. Apply appropriate sealant to both sides of the gasket and place on the gear leg. Place the gear leg in the tunnel (without the propeller). Use

appropriate sealant to ensure that no leakages occur. (NB: See your sealant data sheet for the correct application process.)

9. Install the top motor bracket and gear leg gently together.

10. Fasten the gear leg and the motor bracket with the bolts provided. Tighten to torque as shown.

MG_0617

BOW

BOW

Apply MS Polymer sealant

or equal to both sides of

the gasket

IMPORTANT

Do not apply sealant to

the bolt holes.

8

BOW

Motor bracket

9

10

Tunnel Diameter

Nm lb/ft

18 13,3

Fasten

/140mm

/185mm

Loading...

Loading...