Snap-on Tools Corporation Kenosha, WI 53141-1410 25

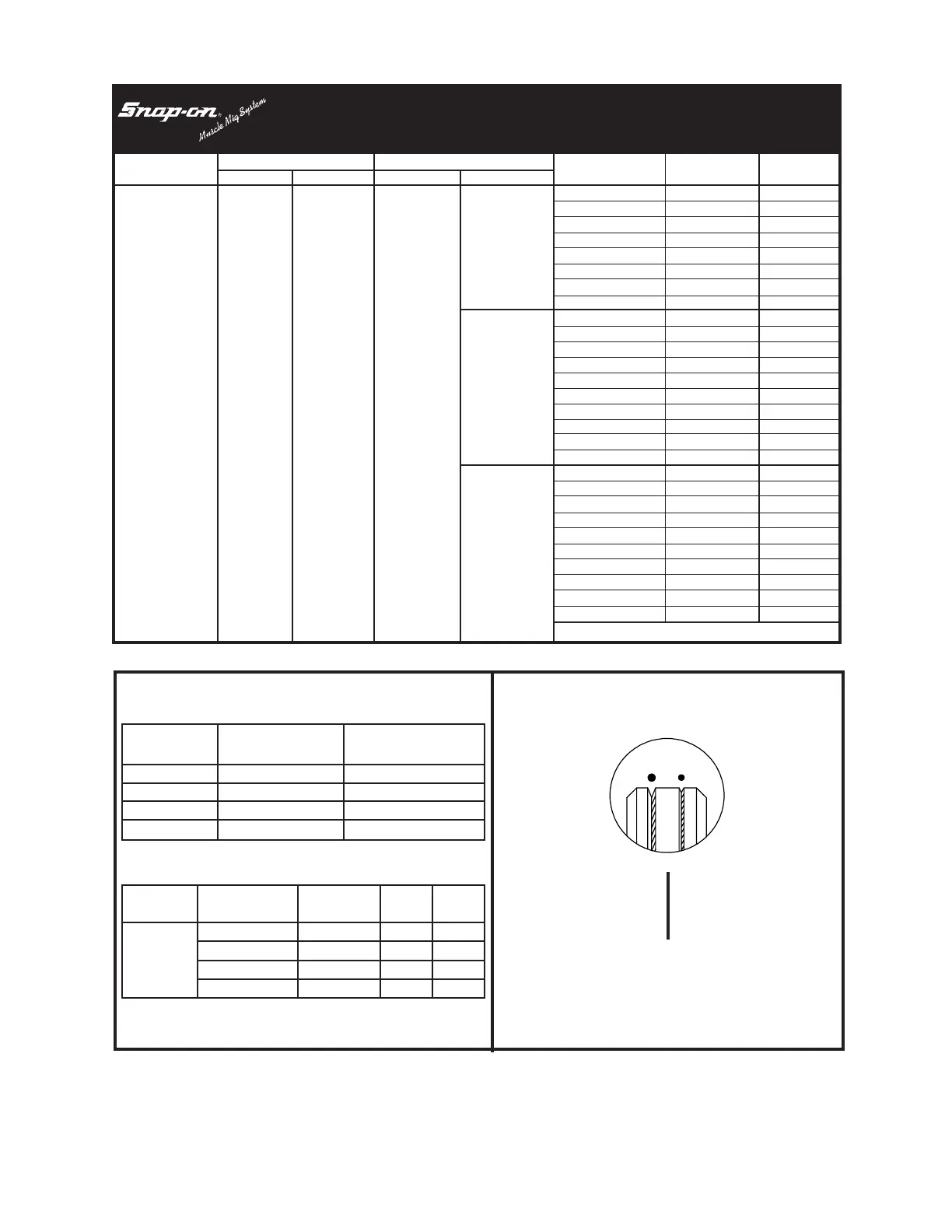

PARAMETER CHARTS

Guide For Setting Welder - Adjust For Best Results

GAS METAL ARC (MIG) PROCESS - DCEP (REVERSE POLARITY)

Note: Settings are approximate and may vary. Adjust for best results.

**Multiple Passes

SHIELDING GAS WELDING WIRE MIG WIRE

MATERIAL TYPE FLOW TYPE SIZE THICKNESS VOLTAGE SPEED

24 Ga.(.024") 1 2 1/2

22 Ga.(.030") 2 3

20 Ga.(.036") 3 4

.023"/ 18 Ga.(.048") 4 4 1/2

.025" 16 Ga.(.060") 5 5 1/2

14 Ga.(.075") 6 7

12 Ga.(.105") 7 8

1/8" 7 8 1/2

24 Ga.(.024") 1 2

22 Ga.(.030") 1 2 1/2

20 Ga.(.036") 2 3

18 Ga.(.048") 3 4

75% .030" 16 Ga.(.060") 4 5

CARBON ARGON 25 ER70S-6 14 Ga.(.075") 5 5 1/2

STEEL 25% CFH 12 Ga.(.105") 6 6

CO2 (Min.) 1/8" 7 6 1/2

3/16" 8 7

1/4" 8 8

20 Ga.(.036") 1 2 1/2

18 Ga.(.048") 2 3

16 Ga.(.060") 3 4

14 Ga.(.075") 4 4

12 Ga.(.105") 5 5

.035" 1/8" 6 5

3/16" 7 5 1/2

1/4" 8 6

5/16"** 8 6

3/8"** 8 6

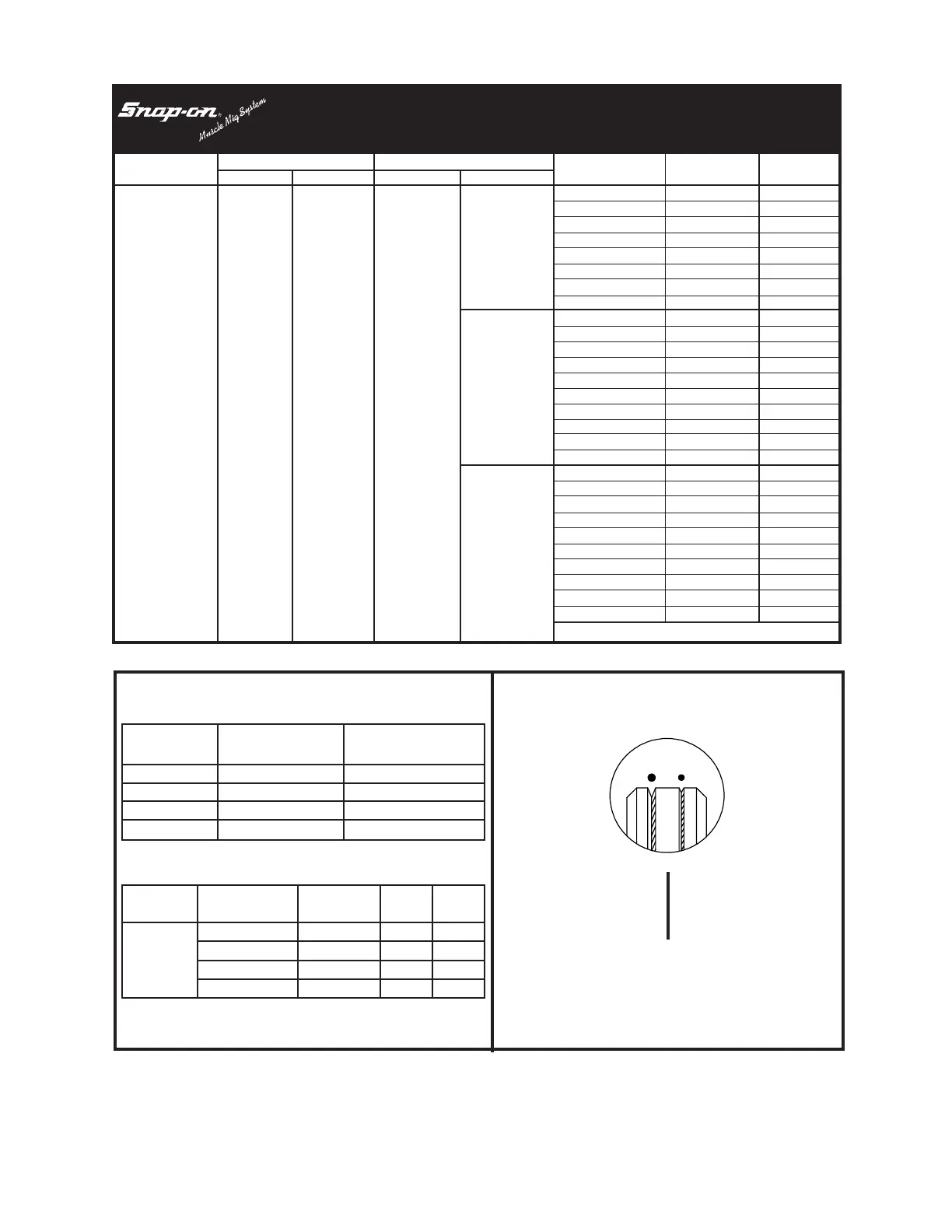

PROPER DRIVE ROLL ORIENTATION

USE LARGE USE SMALL

GROOVE FOR GROOVE FOR

.045" DIA. WIRE .023" - .035"

DIA. WIRE

Position adjusting collar to align drive roll

groove with centerline of wire guide tube.

Then secure drive roll with the washer and the

nut provided.

Note: Settings are approximate and may vary. Adjust

for best results.

SPOT TIME PARAMETERS

TIG WELDING PARAMETERS

WIRE MATERIAL VOLTAGE WIRE SPOT

SIZE THICKNESS SETTING FEED TIME

ER70S-6 24 GA.(.024") MIG 5 4 1

.030" 22 GA.(.030") " 6 5 1

DIA. 18 GA.(.048") " 7 6 1 1/2

16 GA.(.060") " 8 8 1 1/2

VOLTAGE OUTPUT MATERIAL

SETTING AMPERAGE THICKNESS

TIG 1 50 AMPS 18 GA.(.048")

" 2 90 AMPS 14 GA.(.075")

" 3 105 AMPS 1/8" (.125")

" 4 150 AMPS 3/16" (.188")

LB-1366

Loading...

Loading...