13

EN

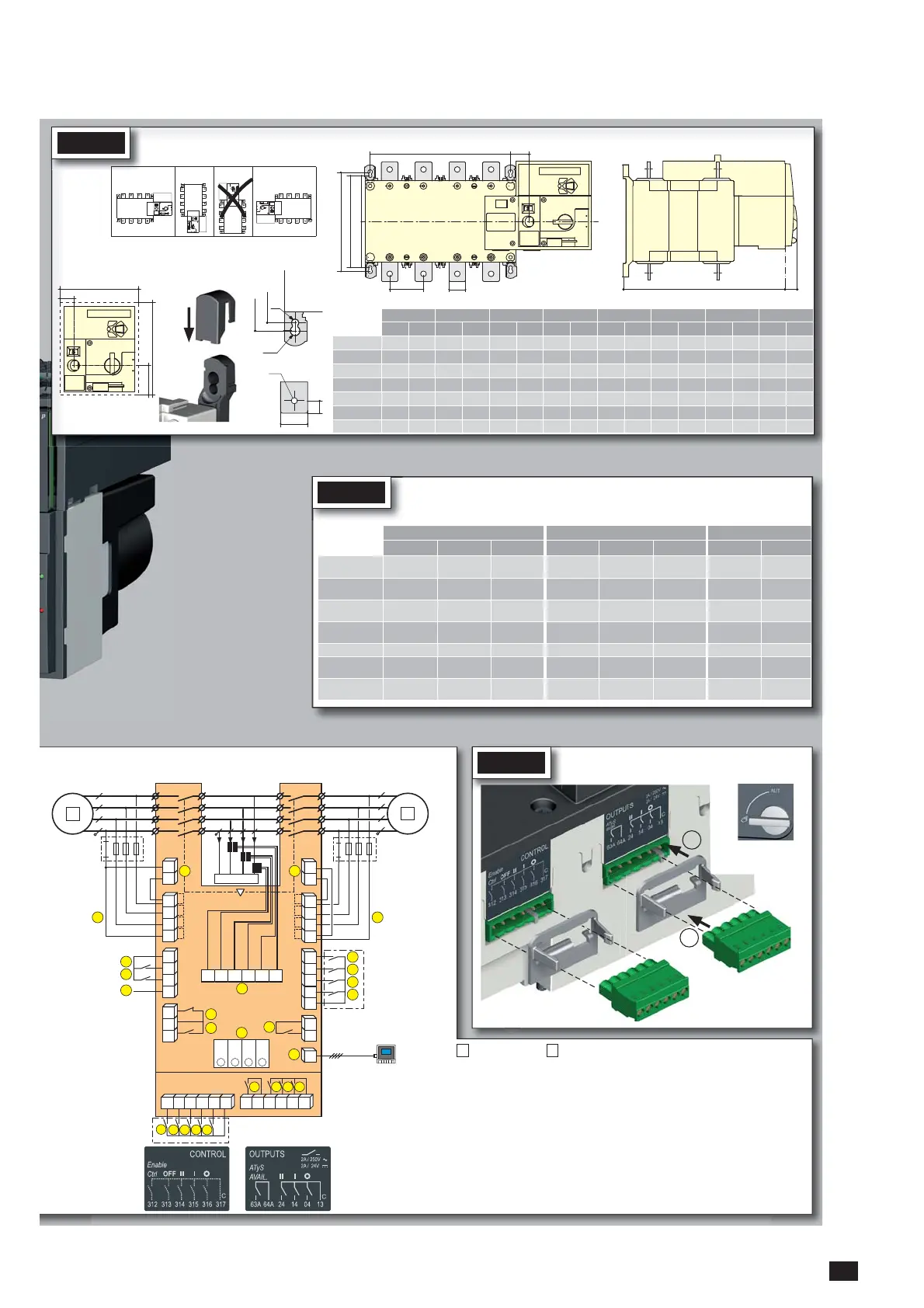

Dimensions in mm.

125 A 160 A 200 A 250 A 315 A 400 A 500 A 630 A

3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P

J 1 34 34 34 34 34 34 35 35 35 35 35 35 34 34 34 34

M 120 150 120 150 120 150 160 210 160 210 160 210 210 270 210 270

T 36 36 36 36 36 36 50 50 50 50 50 50 65 65 65 65

C 244 244 244 244 244 244 244 244 244 244 244 244 320 320 320 320

U 20 20 20 20 20 20 25 25 35 35 35 35 32 32 45 45

W 9 9 9 9 9 9 11 11 11 11 11 11 13 13 13 13

CA 10 10 10 10 10 10 15 15 15 15 15 15 20 20 20 20

M

Fix. 195

Fix. 180

==

J1

UT

C

21

Ø7

Ø9

Fix. 180

Fix. 195

STEP 1

Installation

CA

W

U

Door cut-out for front panel.

50.5

20

138

165

Caution:

Ensure that

the product is

installed on a

flat rigid

surface.

Ok Ok

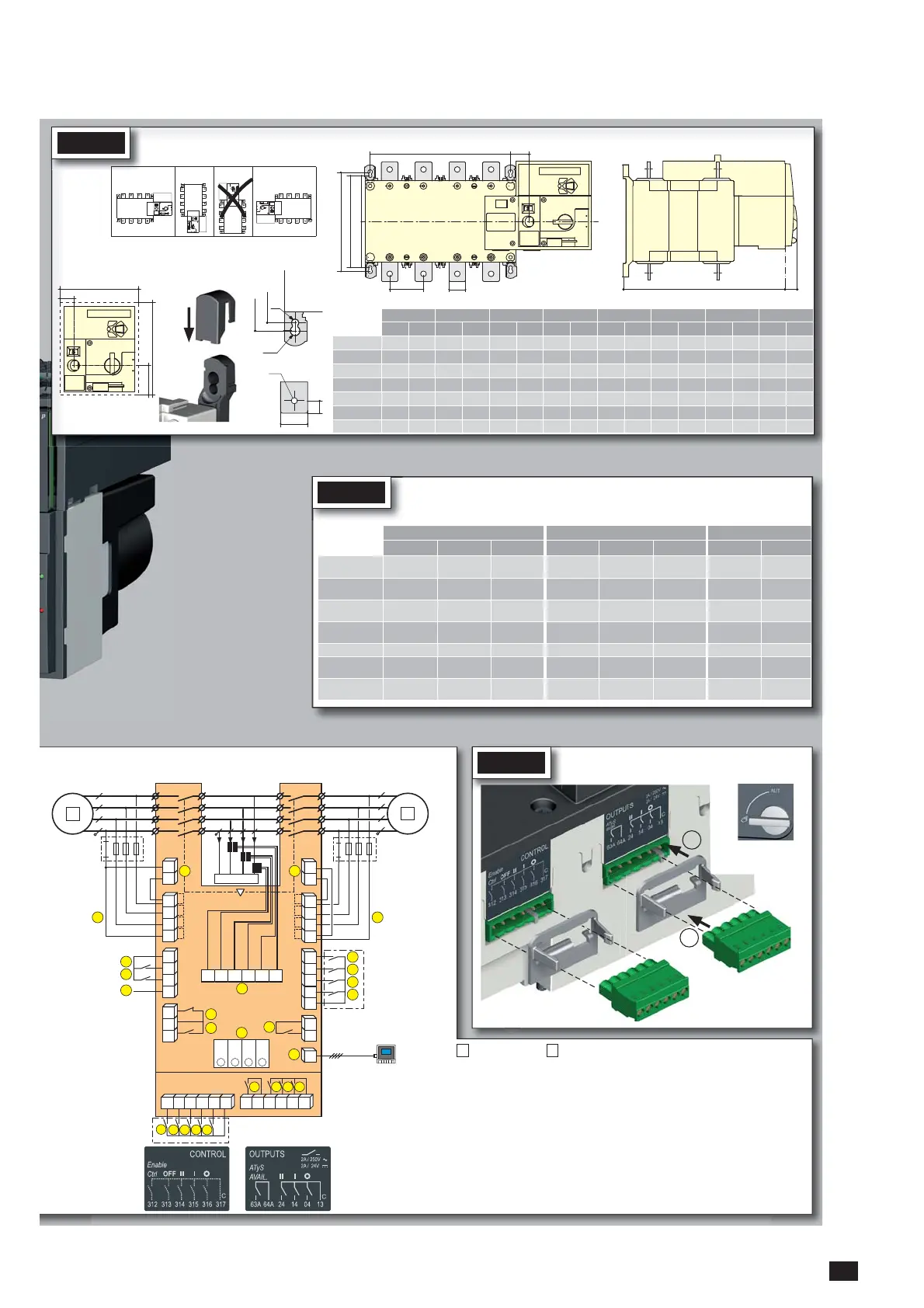

STEP 3

CONTROL / COMMAND Terminals

Ensure that the product is in Manual Mode.

5

6

4

3 2

1

2

7

104 103

312 313 314 315 316 317 63A 64A 24 14 04 13

8 9

10

RJ

102 101

105106

414 413415416417

64B 63B

72

201

71

202

205 206204203

210209208207

74

12

13

14

15

11

1

F1

F2

19

20

16

17

18

L1 L2 L3 N

L1 L2 L3 N

23

23

24

24

LOAD

21

22

R1 R2 S1 S2 T1 T2

Opt. 3

Opt. 2

Opt. 1

4

Opt. 4

3

2

1

Example: Control wiring for a 400VAC application having a 3 phase and neutral supply.

1

2

1

preferred source

2

alternate source

1. Position 0 order

2. Position 1 order

3. Position 2 order

4. Zero position priority order

5.

Remote Control Enable (Priority over Auto)

6. Product Available output (Motor)

7. Position II aux contact

8. Position I aux contact

9. Position 0 aux contact

10. O/P to ATyS D20 remote unit

11. Programmable Output Contact.

By default set to ATS Product

Available - Normally Open

12-15. Programmable Inputs 1-4

16-17. Programmable Inputs 5-6

18. Aux. Supply (207/210) to be used

with ATyS optional I/O modules

19. Contact “Start/Stop Genset” : if S1

is not available the NC contact le

contact (71-72) is close

20. Contact “Start/Stop Genset” : if S1

is not available the NO contact le

contact (71-74) is open

21. Option Module Slots 1 to 4

22. Current Transformer incoming cable

connections

23. Voltage Sensing Inputs

24. Power Supply Inputs

ATyS D20

Remote Control /

Display Unit

Recommended

orientation

FRAME B3 FRAME B4 FRAME B5

125 A 160 A 200 A 250 A 315 A 400 A 500 A 630 A

Minimum cable sec-

tion Cu (mm

2

) at Ith

50 70 95 120 185 240 2

x

150 2

x

185

Minimum cable sec-

tion Cu (mm

2

) at Ith

--- ---

2x30x5 2x40x5

Maximum cable

section Cu (mm

2

)

50 95 150 150 240 240

2x300 2x300

Maximum Cu busbar

width (mm)

20 20 32 32 32 32

50 50

Type of screw

M8 M8 M8 M10 M10 M10 M12 M12

Recommended tight-

ening torque (N.m)

8.3 8.3 8.3 20 20 20 20 20

Maximum tightening

torque (N.m)

13 13 13 26 26 26 26 26

STEP 2

Power Terminal Connections

To be connected using terminal lugs, rigid or flexable busbars.

Loading...

Loading...