Use of High Pressure Pump

ENGLISH 15

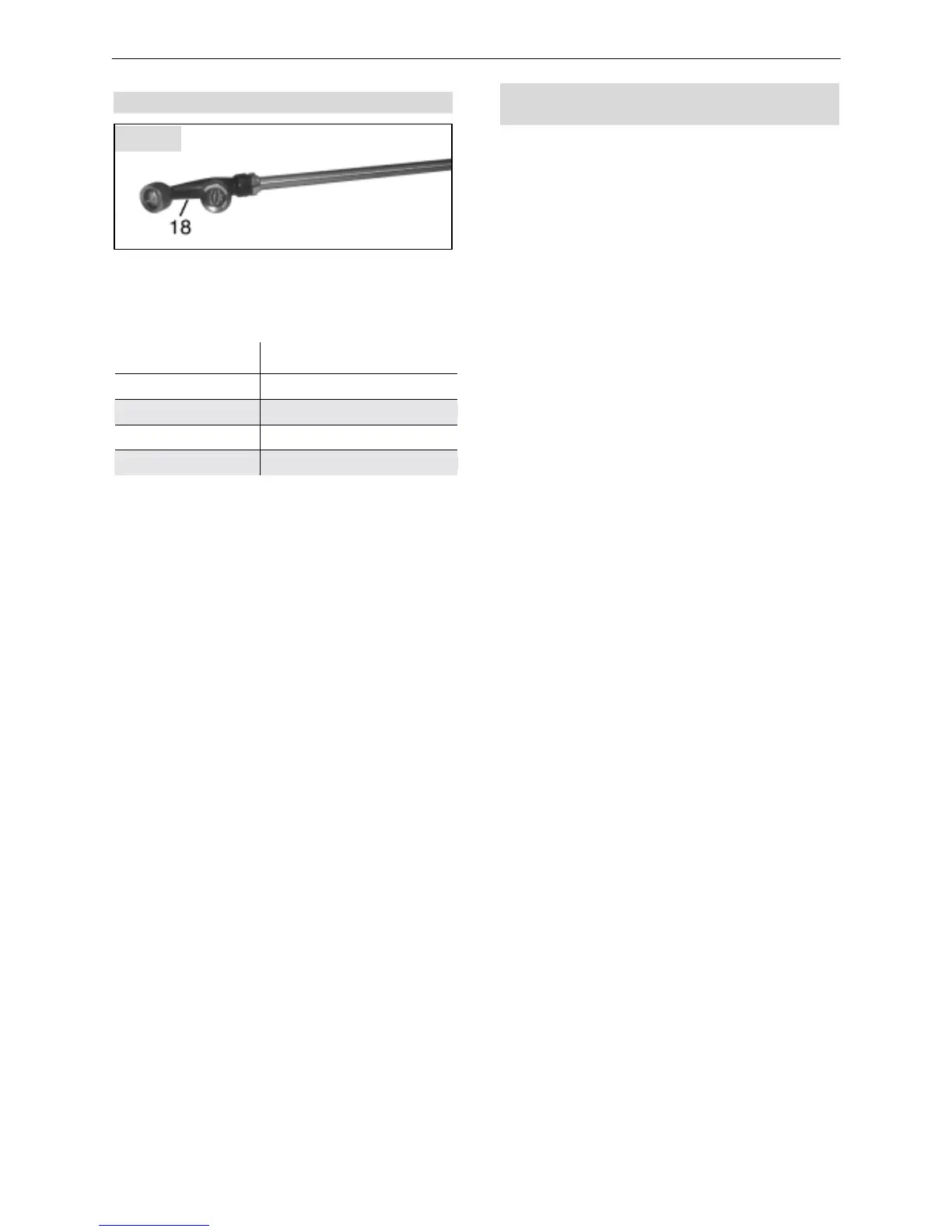

9.3 Spray nozzle / Output volume

A double nozzle (18) is supplied as standard

equipment with the sprayer.

The following general output data is valid for

this nozzle.

9.4 Excess spray chemical / Completing

spraying operation

Stop the engine of the high pressure sprayer as

soon as air is pumped through the nozzle (this

can be heard and seen by the formation of fog

like spray drift). At that point the remaining

spray chemical in the tank is less than 200 ml.

Unless you want to refill the tank and continue

with the spray operation, dilute the remaining

spray volume with 2 litres of water. Apply the

dilution over the already treated area.

Never operate the engine without liquid in the

spray tank. The pump will suffer damage if

operated dry.

After finishing the spray operation, stop the

engine by pressing the stop button (9) until the

engine stops. Let the engine cool down. Empty

and clean the machine according to section 10.3

"Emptying and cleaning of chemical tank".

Thoroughly wash face and hands with water and

soap. Remove the work clothing after spraying.

Clean work clothing regularly.

Note:

After extended operating periods of the high

pressure sprayer, the engine and some parts

(such as the muffler) around the engine can get

very hot. To prevent any consequential damage

we recommend the running of the engine at

idling speed for a short time after the engine

has been used at full speed for longer periods

before the engine is shut down as described.

Spray Pressure in

bar

Output volume in l/min

5 0,7

10 1,2

20 1,7

30 2,0

Fig. 11

Loading...

Loading...