Preparation for use

ENGLISH 9

5. Preparation for use

5.1 Assembly

The high pressure sprayer may only be used

after complete assembly and after the carrying

straps have been adjusted correctly!

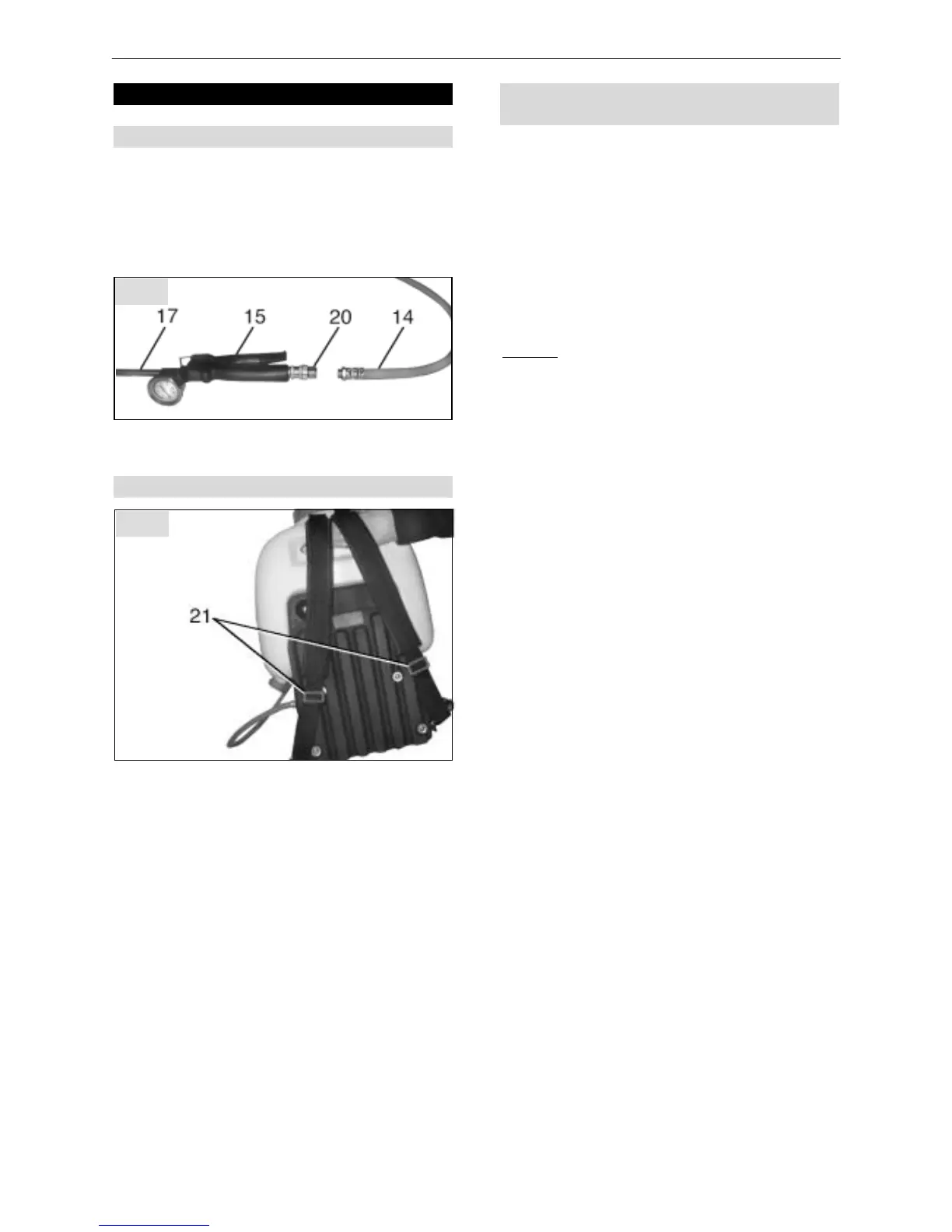

To facilitate packing and transport, the spray

wand (17) and trigger handle (15) are not

attached to the pressure hose (14).

Fasten the pressure hose (14) to the trigger

handle (15) by tightening the hex. Nut (20).

5.2 Adjustment of carrying straps

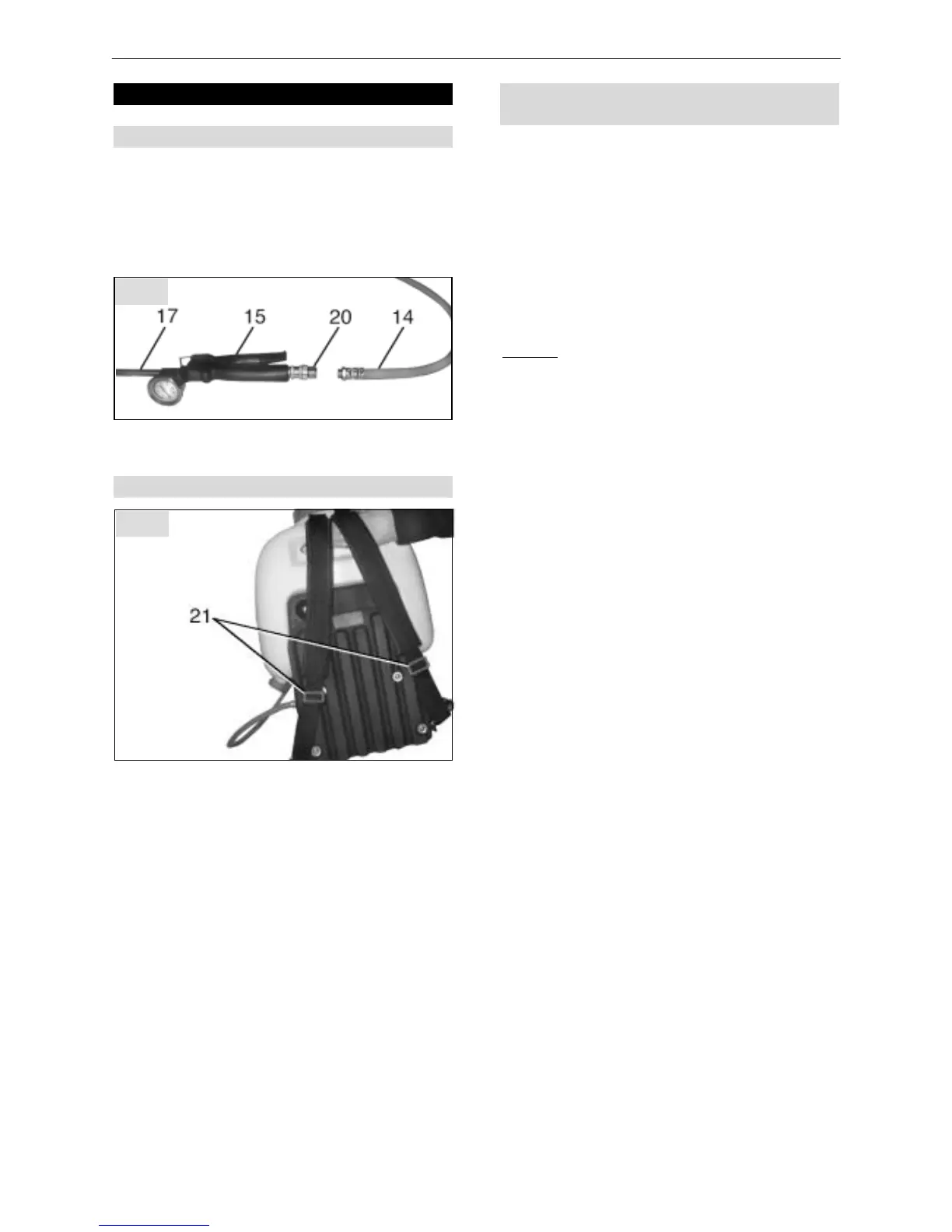

Adjust the length of the carrying strap with the

buckle (21).

The strap is shortened by moving the buckle

upwards. Move the buckle downwards to

lengthen the strap.

The carrying straps are correctly adjusted when

the back cushion of the machine is resting firmly

and securely against the back of the operator.

Do not adjust carrying straps while the machine

is carried on the back.

5.3 Prior to first use and after

extended storage periods

Prior to using the engine driven high pressure

sprayer for the first time and after extended

storage periods we recommend that you check

the correct operation of the complete machine.

Also check all parts and hoses which carry fuel

and chemical liquid for any leakage. This should

be done before you mix the chemical solution.

After reading the manual thoroughly test the

machine as described in the following

paragraph.

Observe all safety instructions while

testing the machine.

Test run

:

Fill the liquid tank with approx. 5 litres of water

after carrying out a successful visual check of the

machine. Fill the fuel tank with the correct fuel

mixture as described in section 6 "Fuelling " and

start the high pressure sprayer as described in

section 8 "Starting engine / Stopping engine"

for a test run. Check all parts and hoses which

carry fuel or chemical liquid for leakage. Check

the efficient operation of the throttle lever (8),

the operating handle (15), pressure gauge (16)

and the stop button (9).

Hint: To get a feel for the machine and to gain

confidence in the high pressure sprayer we

suggest you carry out several spray trials

with water only at various pressure

settings.

Note: The pressure gauge will only provide a

pressure reading when the operating

handle is in open position during the

spraying process.

If irregularities, leakages, visual damage (even

on the carrying frame), limited function or

incorrect adjustments are detected, do not start

any spray operations but have the high pressure

sprayer checked by a specialized service centre.

Fig. 3

Fig. 4

Loading...

Loading...