Operating and Maintenance Instructions

ENGLISH 20

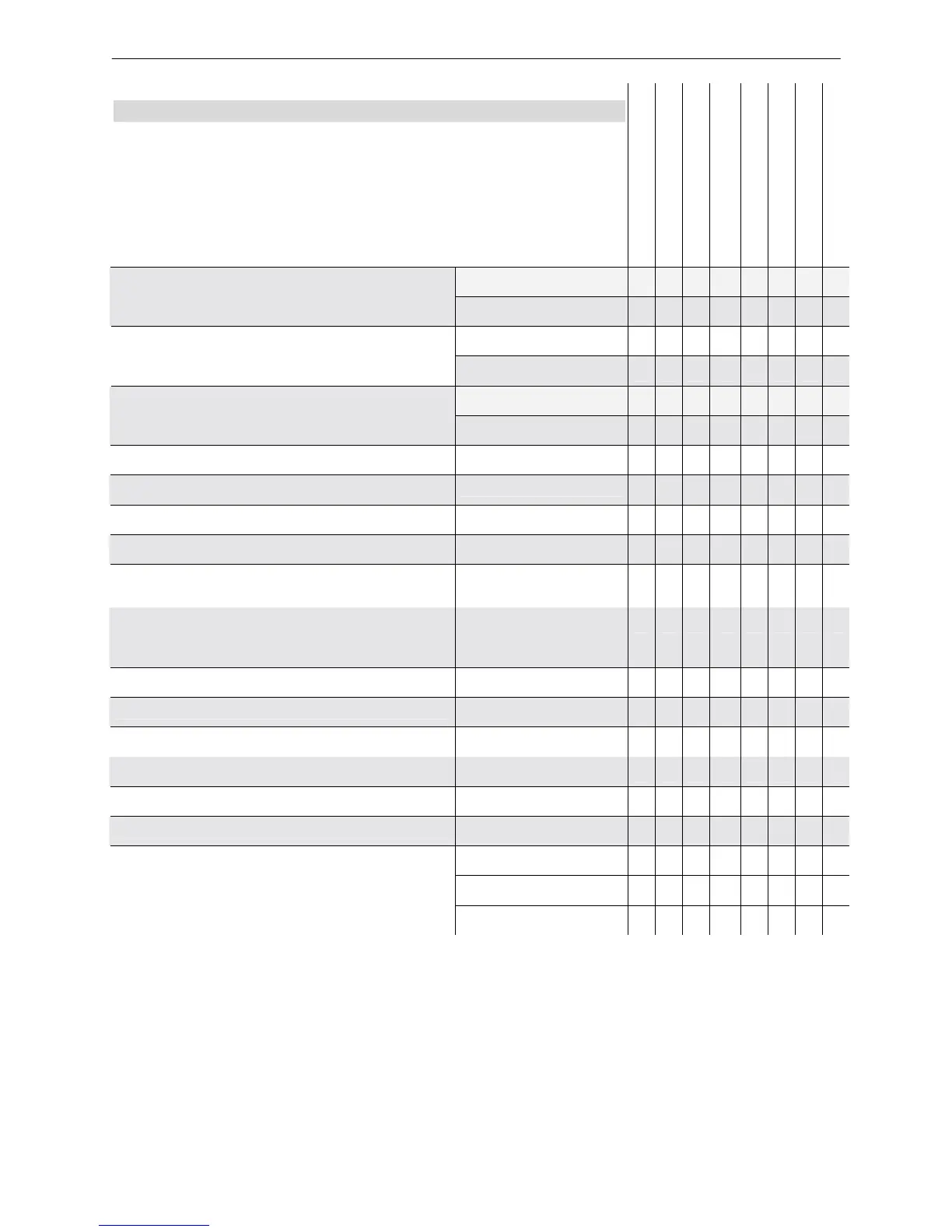

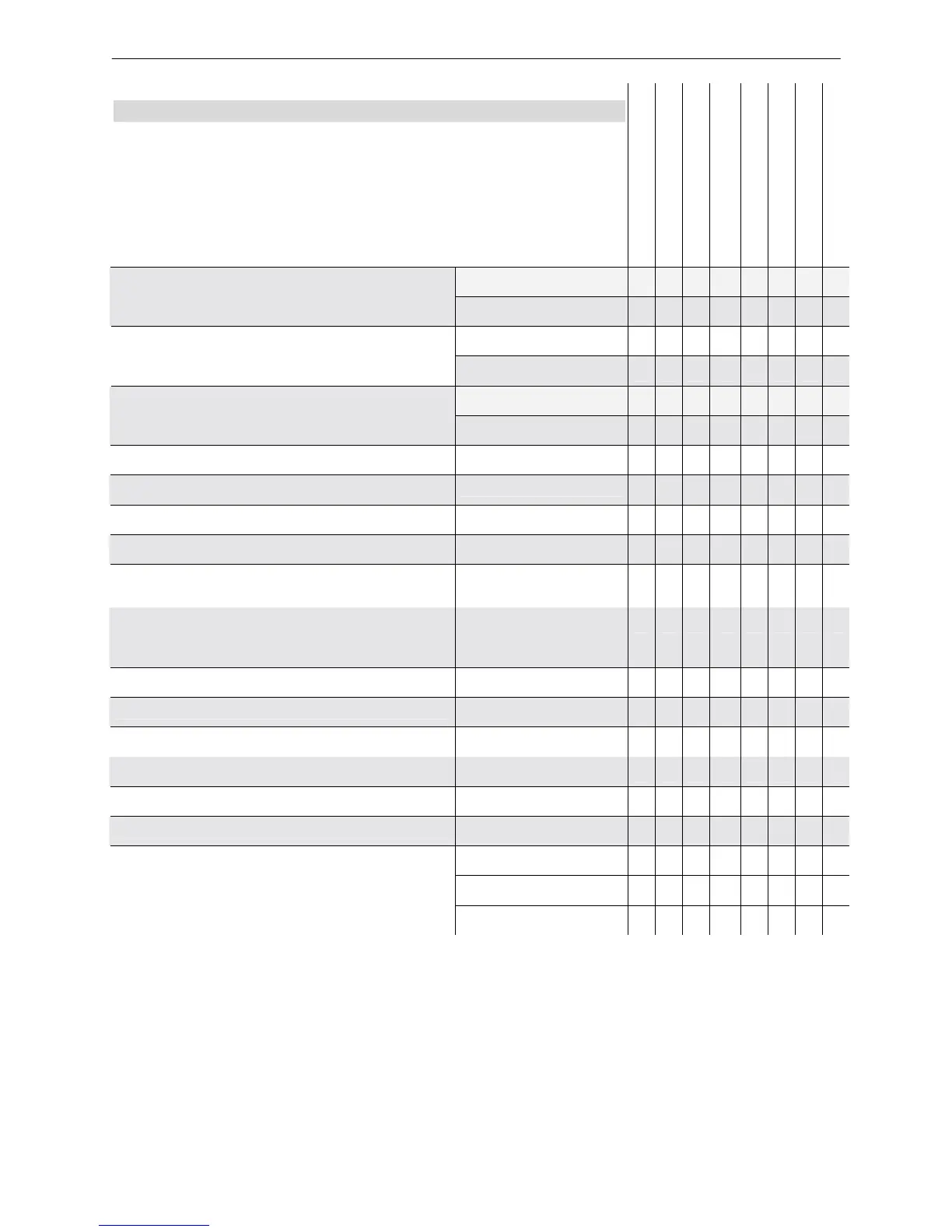

10.10 Maintenance Plan

The following hints are based on normal operating conditions.

For special conditions, such as long, daily use, the recommended

maintenance intervals should be shortened accordingly

before starting work

daily

weekly

after 5 hours

after every 50 hors work

after every 100 hours work

as required

before spray season

Check idling speed

X

Carburettor

Adjust idling speed

X

Clean

X

Air filter

Replace

X

Adjust electrode gap

X X

Spark plug

Replace

X X

Cooling air inlet

Clean

X X

Cylinder cooling fins

Clean

X X

Fuel tank

Clean

X X

Fuel filter

Replace

X

All accessible screws

(except for adjustment screws)

Re-tighten

x

1)

X

Operating controls

(Stop-button, throttle lever, operating handle,

pressure regulator)

Check function

X

Exhaust

Visual check

X

Spray output volume and distribution

Check

X

Liquid tank

Empty and clean

X

Liquid tank inlet filter

Clean

X X

Spray nozzle

Clean

XX

Liquid or fuel leaks

Check

X

Visual check

X

Test run with water

X

Complete machine

Clean

XX

1)

! once

All maintenance jobs should be done regularly. If necessary, authorize a specialist service centre to

maintain the machine for you. The owner of the machine is responsible for:

• Any damage caused by the lack of maintenance, improper maintenance or late maintenance and

repairs

• Consequential damage - including corrosion - from improper storage

Loading...

Loading...