Operating and Maintenance Instructions

ENGLISH 17

Regularly clean the inlet funnel filter and the

spray nozzle with a soft brush. Never use the

mouth to blow through the nozzle!

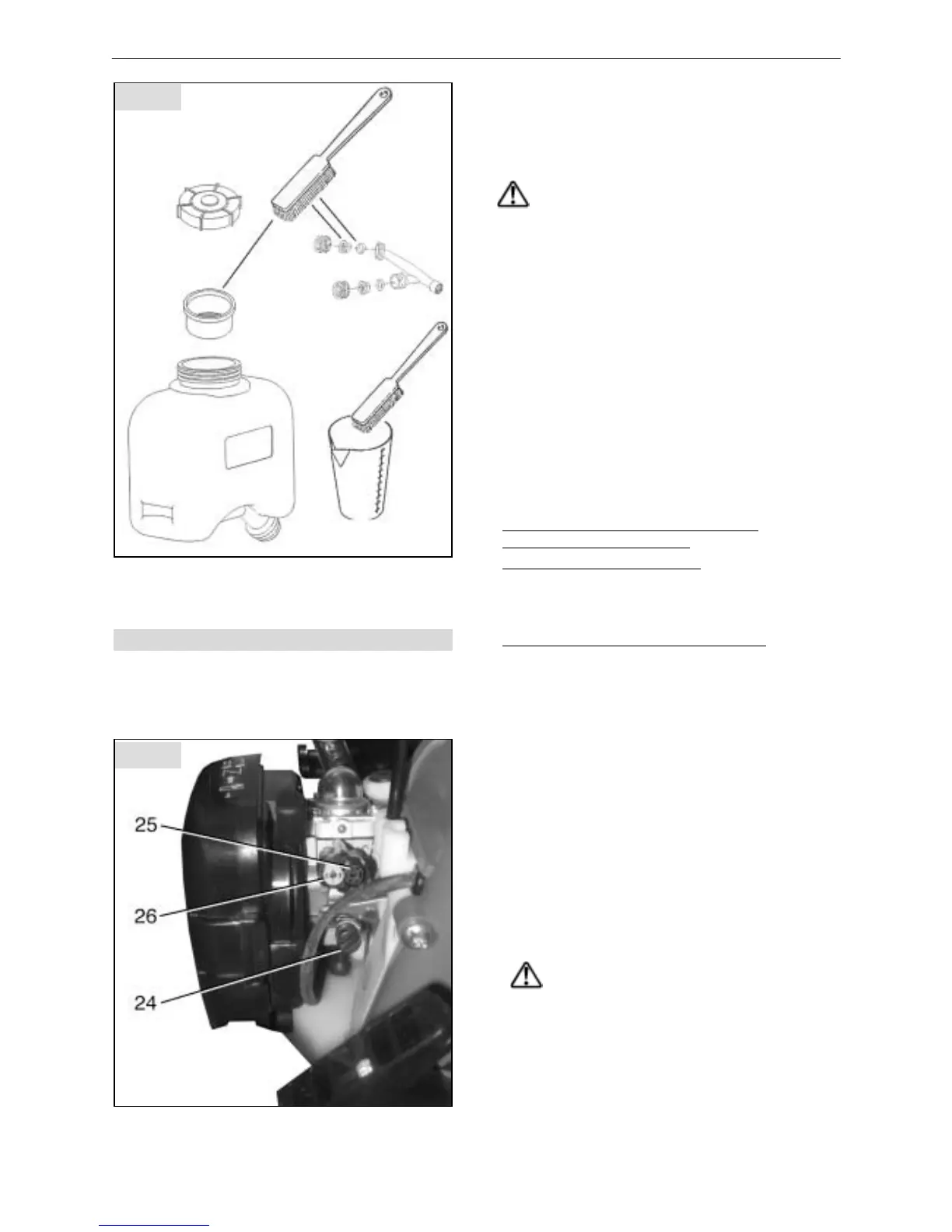

10.4 Carburettor adjustment

The carburettor has been adjusted optimally at

the factory. Depending on the operational

altitude (mountains or low lying areas) a re-

adjustment of the carburettor may be required.

Mod.: Carburettor with limitercaps

The carburettor has 3 adjustment screws:

• Idling set screw "T" (24)

• Low speed mixture screw "L" (25)

• High speed mixture screw "H" (26)

The regulating screws for idle mixture "L"

(25) and full load mixture "H" (26) must

only be adjusted by qualified mechanics.

Turn the idling set screw "T" (24) to adjust the

idling speed to the data provided in the

technical specifications. An engine speed

counter should be used for this job.

• If the idling speed is too high, turn the idling

set screw "T" anti-clockwise.

• If the idling speed is too low (engine stops)

turn the idling set screw "T" clockwise until

the engine runs smoothly.

If the idling speed cannot be set correctly with

the idling set screw "T", an authorised service

centre should be requested to tune the

carburettor.

The following instructions are for

authorised service shops

Using the D-CUT carburettor:

Key (SOLO part no: 00 80 537) to correct settings

on the idle mixture screw "L" (25) and on the

full load screw "H" (26).

Using the carburettor with limitercaps:

The regulating screws for idle mix and full

charge mix can only be adjusted in a limited

range.

Clean the air filter before adjusting the low

speed adjustment screw!

Let the engine run warm before adjusting the

engine speed.

Medium engine idling speed = 2800 rpm

Max. Admissible engine speed = 6700 rpm

The carburettor is tuned for optimal

engine performance. An engine speed

counter is required to adjust the

carburettor correctly!

Do not adjust the engine to a higher speed.

Excessive engine speed can lead to major engine

damage!

Fig. 13

Fig. 14

Loading...

Loading...