Registered Quality System to ISO 9001:2008

29/60

Form 912

sorinc.com

913-888-2630

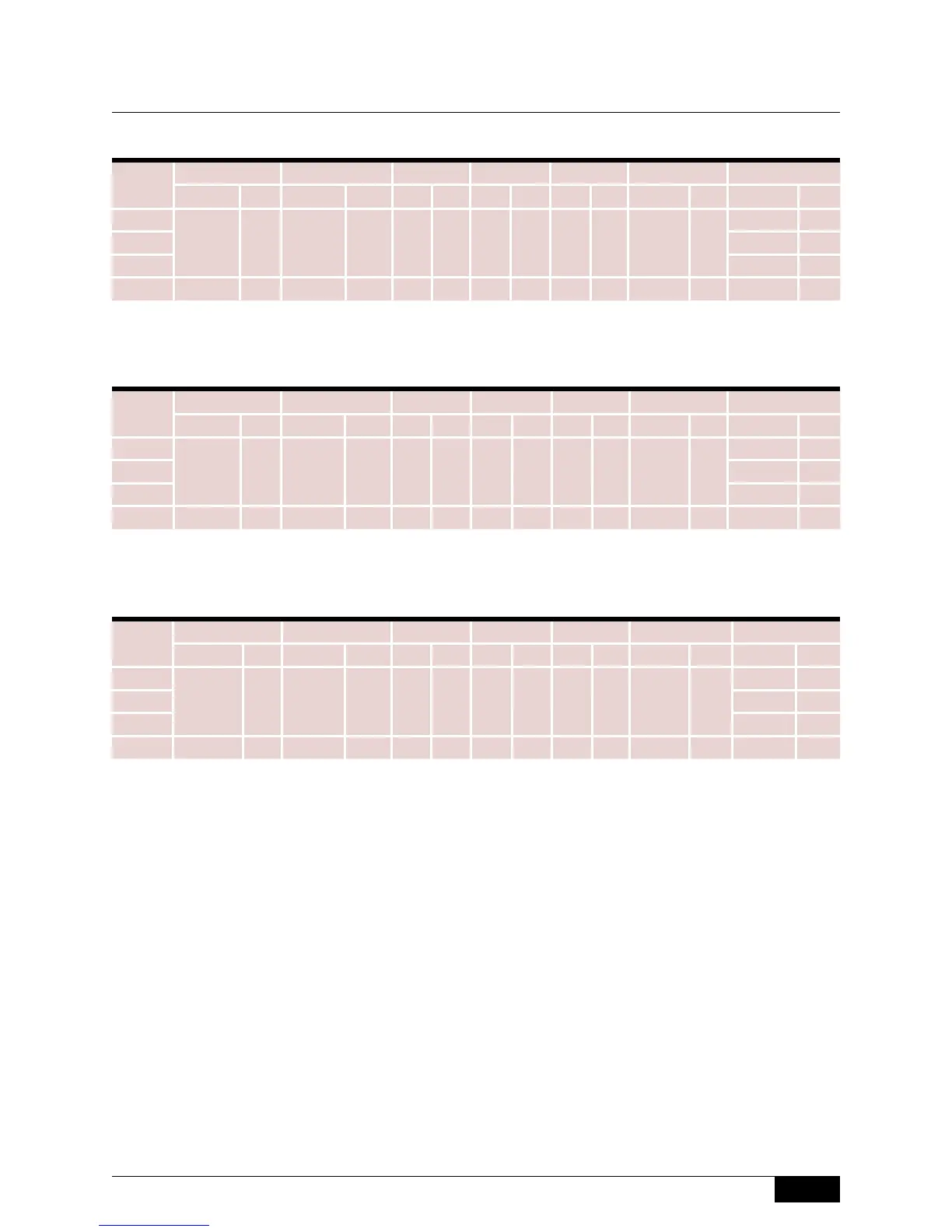

Chamber Dimensions

1” Connections

1-1/2” Connections

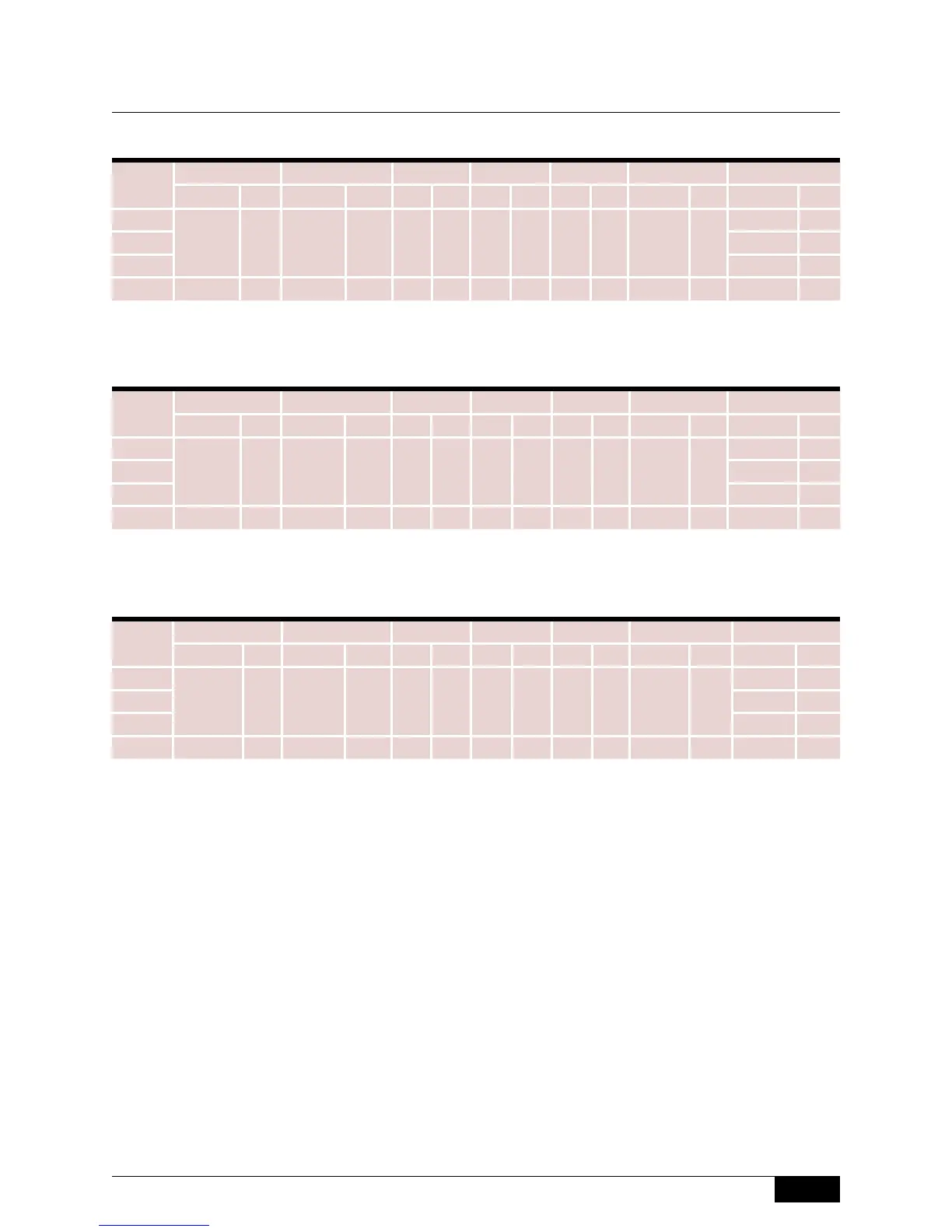

2” Connections

741-743 and

802 Series

Model

D

1, 2

E

1, 2

F

4

G H

4

I

2

L

2

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

741

13 330 3-1/4 83 6 152 16 406 16 406 3-3/4 95

19-5/16 491

742 19-1/2 495

743 19-7/8 505

802 12-3/4 324 3-7/8 98 8 203 16 406 16 406 6-3/4 171 20-3/4 527

Model

D

2

E

2

F

4

G H

4

I

2

L

2

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

741

13 330 3-1/2 89 6 152 16 406 16 406 3-3/4 95

19-5/16 491

742 19-1/2 495

743 19-7/8 505

802 12-7/8 327 4 102 8 203 16 406 16 406 6-3/4 171 20-3/4 527

Model

D

2

E

2

F

4

G H

4

I

2, 3

L

2, 3

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

741

- - - - 6 152 16 406 16 406 3-3/4

5

95

5

19-5/16

5

491

5

742 19-1/2

5

495

5

743 19-7/8

5

505

5

802 13-3/16 335 4-5/16 110 8 203 16 406 16 406 7-3/4 197 21-5/16 541

Notes

1. Dimensions D and E apply to socket-weld connections only. Consult factory for NPT dimensions.

2. Consult factory for dimensions for materials other than carbon steel.

3. Applies to socket weld or NPT process connections only.

4. Consult the factory if weld neck process flanges are required. Dimensions may vary from those shown above.

5. Applies to flanged process connections only.

Loading...

Loading...