Registered Quality System to ISO 9001:2008

52/60

Form 912

sorinc.com

913-888-2630

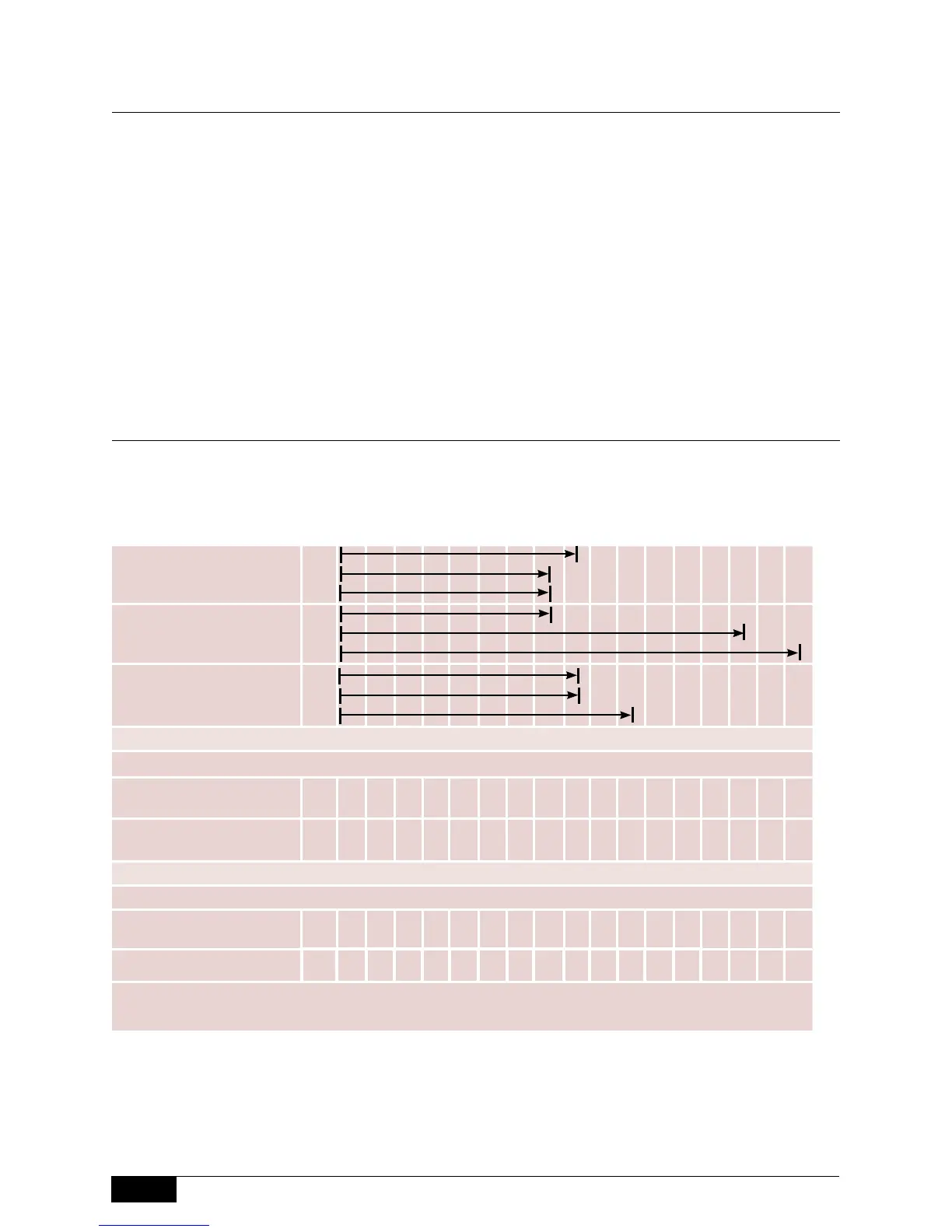

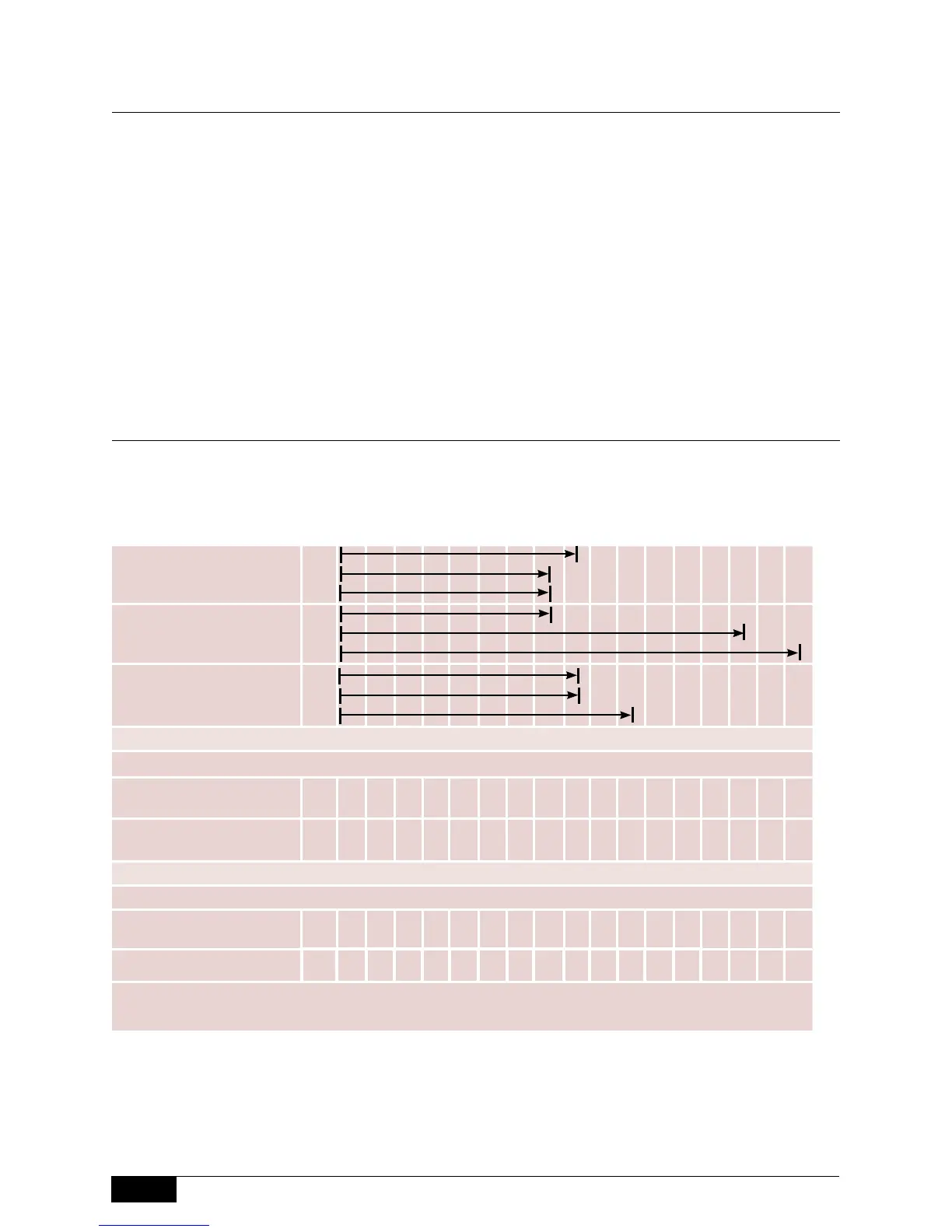

There are two sections to the chart, Steam Heat and Dry Heat. Fundamental differences in condensing

(steam) and non-condensing (dry) heat require different methods of protection.

Steam Heat processes carry it’s heat with the vapor. These processes effectively heat every portion of their

enclosure. To reduce the heat effects of condensing processes, we must either condense or physically block

the vapor. SOR uses a condensing system to avoid the sealing problems associated with blocking the steam.

Dry Heat processes transfer heat through direct conduction. Heat is only passed to the areas where they

touch the enclosure. Therefore, radiant heat is the only concern with these processes. This may be resolved by

adding distance between the process and the protected portion of the control.

To use the selection chart, first select the column that represents the desired maximum temperature. Select

a chamber material that is allowable in the chosen column. Move down to the proper process type section,

Steam Heat or Dry Heat. Within that section, select a switch mechanism from those listed in the chosen

column. The symbol will indicate if a temperature reduction device is required.

High Temperature Selection

High Temperature Selection Chart

Mechanical

Level Switches

≤ 600

o

F(316

o

C)

≤ 650

o

F (343

o

C)

≤ 700

o

F (371

o

C)

≤ 800

o

F (427

o

C)

≤ 850

o

F (454

o

C)

≤ 900

o

F (482

o

C)

≤ 950

o

F (510

o

C)

≤ 1000

o

F (538

o

C)

0-400

o

F (204

o

C)

≤ 450

o

F (232

o

C)

≤ 550

o

F (288

o

C)

≤ 750

o

F (399

o

C)

≤ 500

o

F (260

o

C)

Designator

A106B Carbon Steel

304/304LSS

316/316LSS

A

C

A333 GR.6

A335-P11 Chrome Moly

A335-P91

Hastelloy C

Alloy-20

Monel-400

Steam Heat Applications

Switch Mechanism (Select one)

Hi-Temp Dry Contact

or Mini-Hermet

Hi-Temperature Ceramic/SS

B/V

Y

v

v

v v

v

v

v v v

v

Dry Heat Applications

Switch Mechanism (Select one)

Hi-Temp Mini-Hermet

or Dry Contact

B/V

Hi-Temperature Ceramic/SS

Y

For proper cooling, temperature extensions and finned extensions must not be insulated or placed inside an enclosed structure. High ambi-

ent temperatures (over 100ºF/38ºC), intense direct sunlight or heat loading from adjacent piping or vessels will affect cooling

performance. Consult the factory if any of these conditions exist.

Features

Chamber Material (Select one)

≤ 1050

o

F (566

o

C)

≤ 1100

o

F (593

o

C)

≤ 1150

o

F (621

o

C)

≤ 1200

o

F (649

o

C)

= Switch Only v = Finned Extension = Temperature Extension

Loading...

Loading...