NEW

NEW

NEW

Technical Manual 2006

38

SRAM T3

ASSEMBLY

Caution:

• Only install additional axle attachments

(e.g. struts) between nut and retaining

washer.

• Cable stop bracket: dimensions

see Fig. 9.

• Axle end must protrude by min. 1 mm

to max. 4 mm beyond the nut (1, Fig. 5).

• Mount the brake lever using a suitable

frame clamp (2, Fig. 4 resp. Fig 11).

Caution:

Mount the brake lever between the two

straps of the frame clamp.

The clamp must be seated on the frame

without play.

Use a self-locking nut! Tightening

torque: 2 – 3 Nm (18 – 27 in.lbs.).

Caution:

Check that all the brake system

components are functioning properly!

Spoke lengths are approximate values. They must be checked through lacing attempts

and adjusted accordingly.

Tire Size Cross Length MH 3115/3105 Length MH 3125

28 / 36 Holes 28 / 36 Holes 36 Holes

47–406 20" x 1.75 x 2 2 x / 3 x 182 mm / 184 mm —

37–490 22" x 1

3

/

8

— / 3 x — / 228 mm —

47–507 24" x 1.75 x 2 2 x / 3 x 234 mm / 235 mm —

37–540 24" x 1

3

/

8

— / 3 x — / 254 mm —

47–559 26" x 1.75 x 2 2 x / 3 x 258 mm / 262 mm 253 mm

37–590 26" x 1

3

/

8

— / 3 x — / 254 mm 273 mm

47–622 28" x 1.75 2 x / 3 x 289 mm / 292 mm 285 mm

28–622 28"x1

1

/

8

— / 3 x — / 292 mm 285 mm

32–622 28"x1

5

/

8

x 1

1

/

4

— / 3 x — / 292 mm 285 mm

37–622 28"x1

3

/

8

x 1

5

/

8

— / 3 x — / 292 mm 285 mm

28–630 27"x1

1

/

4

fifty — / 3 x — / 297 mm 287 mm

32–630 27" x 1

1

/

4

— / 3 x — / 297 mm 287 mm

Spoke length table:

ASSEMBLY HUB

• Lace the wheel as normal. See spoke

length table.

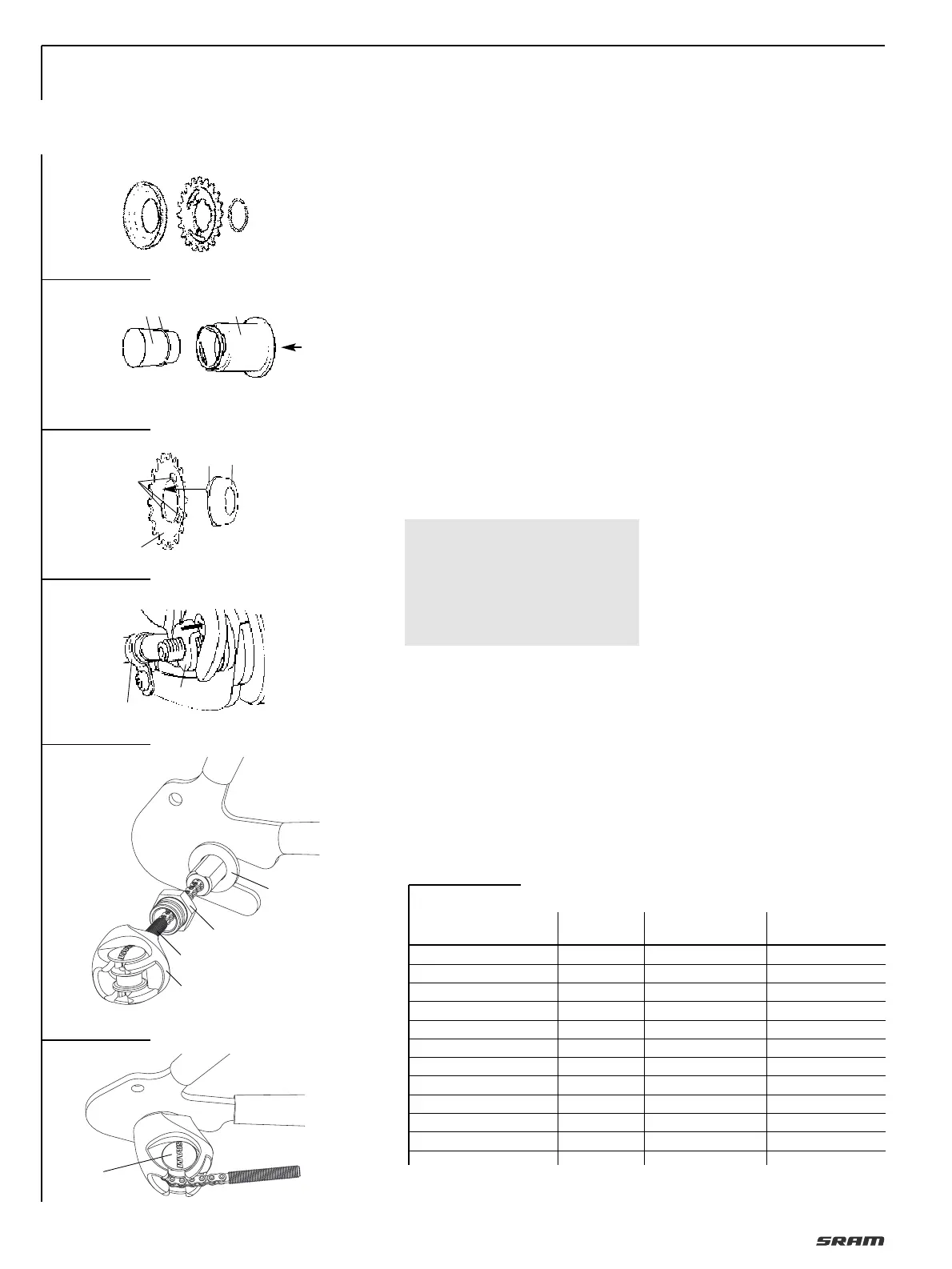

• Place the dust cap (1, Fig. 1) and

sprocket (2) on the driver.

• Push sprocket circlip (3, Fig. 2) onto the

cone of tool sleeve (4). Place tool sleeve

with large diameter on the driver.

• Push the spring end of sliding sleeve (5)

of the tool over the tool sleeve. Thrust

sliding sleeve in direction (6), this forces

circlip into the recess of the driver.

• Remove tool and check that the circlip is

seated correctly.

• Turn dust cap (7, Fig. 3) until the three

lugs (8) are between the three beads (9)

on the sprocket (10).

• Position dust cap and push towards

sprocket until it is felt to lock into place.

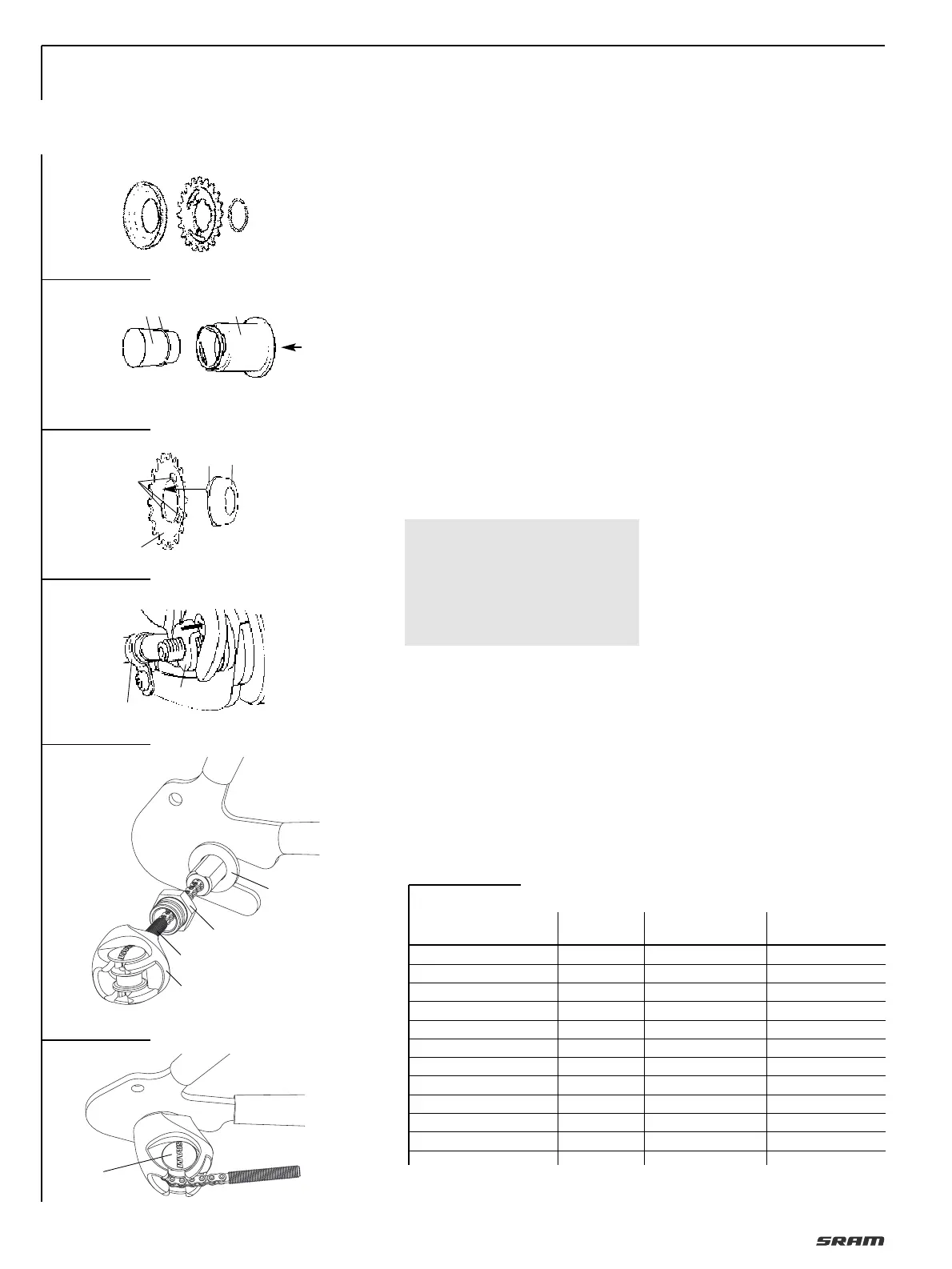

• Screw tension chain (2, Fig. 5) into the

axle end.

• Placing the wheel in the rear frame.

• Mount the chain.

• Fit new retaining washer (3,5 mm thick)

on left axle end (1, Fig. 4). The serrations

must bear against the dropout and the

lug must engage in the dropout slot.

Advice:

For bicycles with chain tensioner use

previous retaining washers (2 pieces,

2 mm thick) – see Tech. Manual 2005.

• Tighten up special type axle nut (1, Fig. 5)

and axle nut at other axle end. Tightening

torque 30 – 40 Nm (266 – 350 in.lbs.).

• Guide tension chain (2) trough

deflection pulley (3).

• Position deflection pulley at axle nut and

push until it is felt to lock into place.

Turn deflection pulley until the circular

area is at the top (4, Fig. 6).

1

2

3

4

5

6

10

9

8

7

12

2

1

3

4

5

45

6

3

Mounting Tool

Part No. 0582 104 000

1

2

Loading...

Loading...