Technical Manual 2006

39

SRAM T3

ASSEMBLY

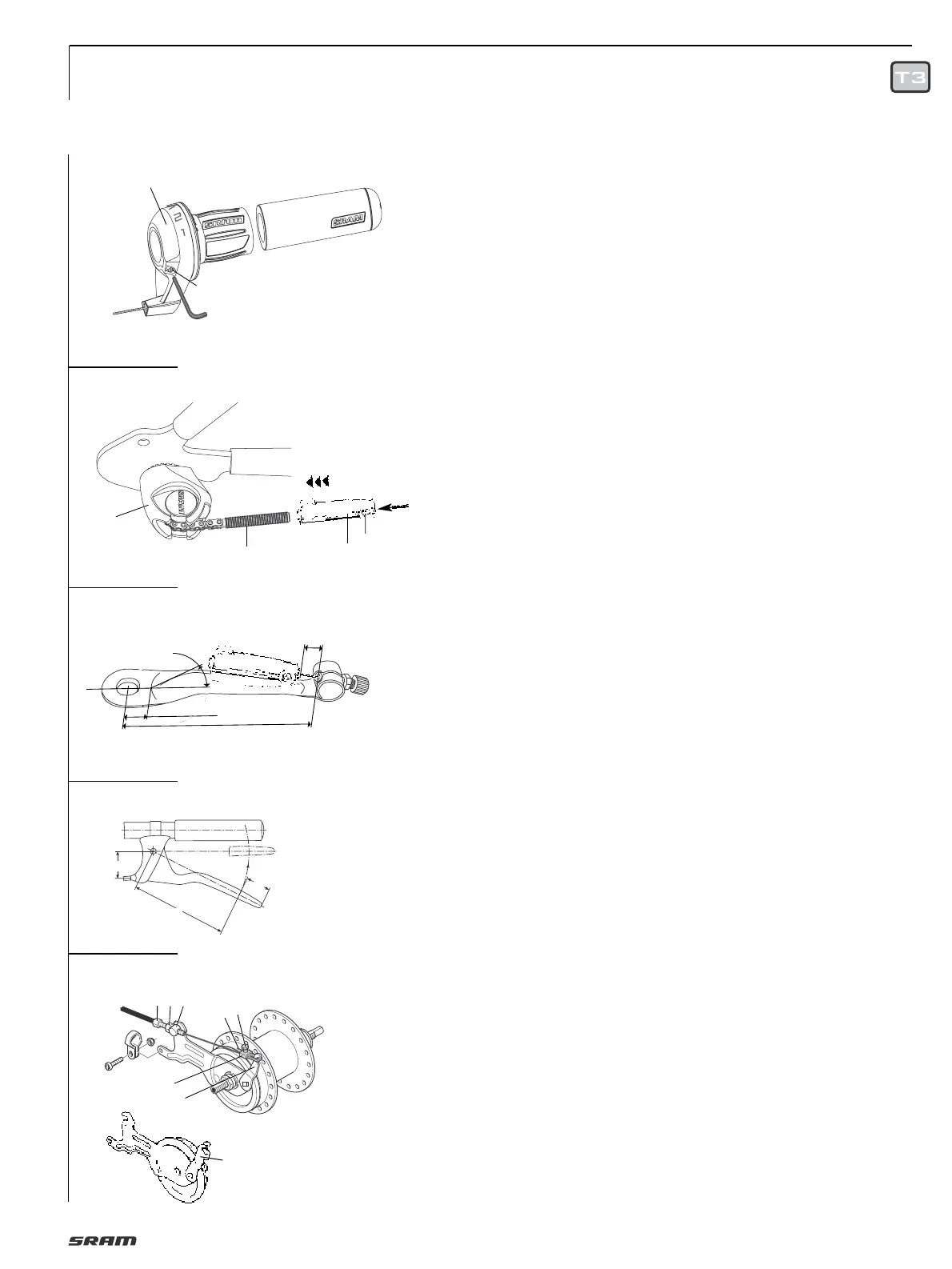

ASSEMBLY SHIFTER

• Slide shifter (1, Fig. 7) onto handlebar.

• Mount fixed grip (2) onto end

of handlebar.

• Without applying pressure, slide shifter

against fixed grip, adjust shifter on

handlebar and tighten with bolt (3). Allen

key 2.5 mm, torque 1,7 Nm (15 in.lbs.)

• Not recommended for use on thin walled

aluminum handlebars such as Hyperlite

©

type handlebars.

Caution:

• Never use lubricants or solvents to

install fixed grips.

Fixed grips provide an axial safety

function. For this reason, they should be

mounted in such a way as to make sure

they do not slip off handlebar.

• Check that the shifter and brake lever

function properly and are unobstructed

(realign if necessary).

• Never ride without the fixed grips. The

turning grip may loosen from housing

and slip off handlebar – this can result

in severe injury or death.

INSTALLING CABLE

• When fitting the cable avoid small radius.

Use only compressionless cable housings

with resin liner inside and capped.

• Screw the cable stop clamp and cable

pully clamp on the down tube or seat tube.

• Secure the lubricated shift cable at

equidistant intervals on the frame

(in case of continuous cable housing).

Advice:

To avoid malfunction the cable frictional

force must not exceed 6 N (1.4 lbs.).

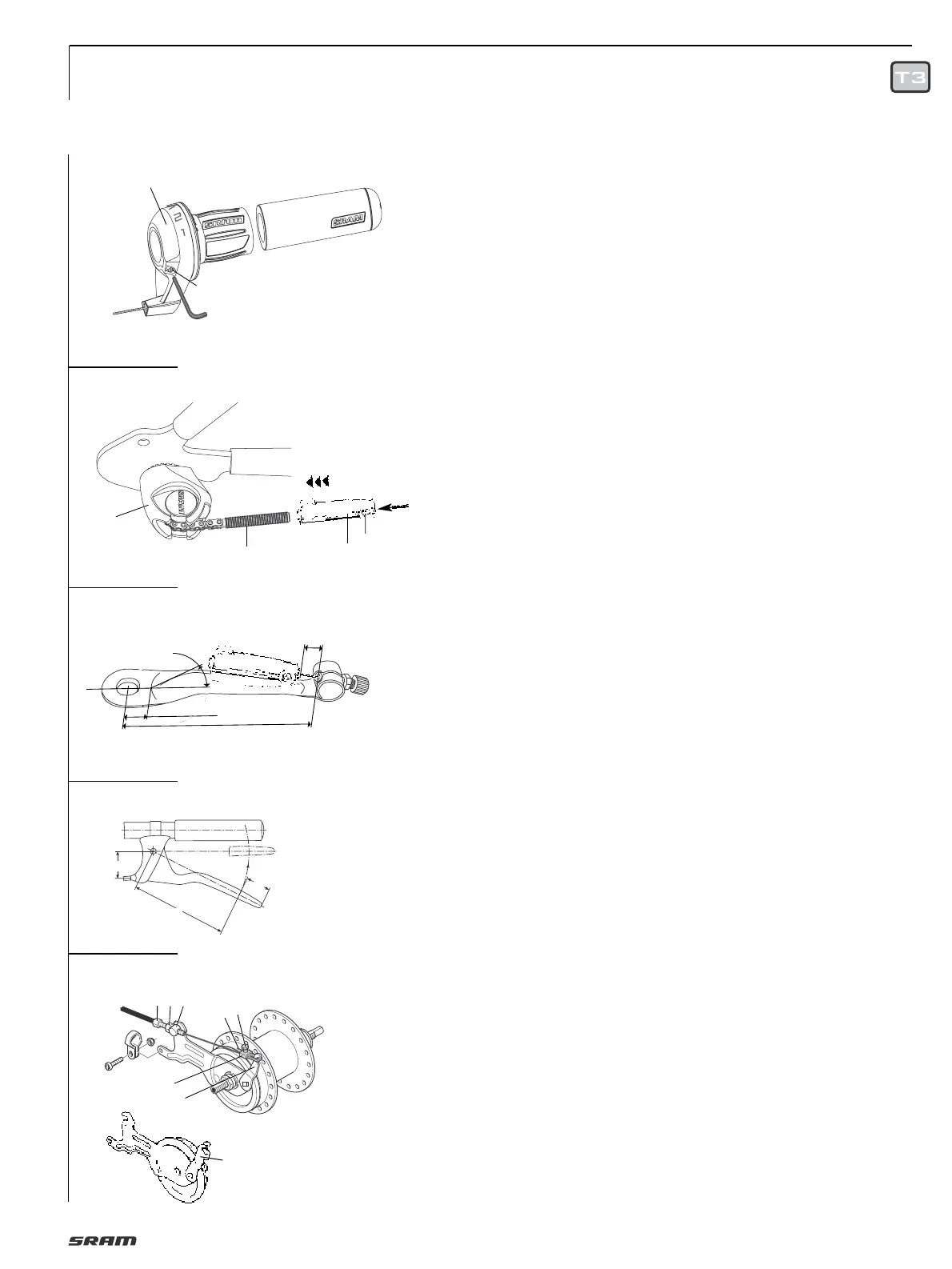

• Feed the shifter cable into the locating

sleeve (5, Fig. 8), fix at the appropriate

length (cable stop bracket: see Fig. 9)

using the clamping bolt (1).

Allan key 2.5 mm, tightening torque

1.5 Nm (13 in.lbs.). Shorten any cable

which is sticking out.

• Connect to the hub: push locating sleeve

(2, Fig. 8) loosely onto small pull rod (3).

ADJUSTMENT

• Place the shifter in gear position "3".

Move the crank to check that the gear

is engaged.

• To make the adjustment, the cable must

be taut in third gear to be able to transfer

a shift movement directly to the hub.

• Push locating sleeve (2, Fig. 8) onto the

small pull rod (3) until the control cable

is taut. Make sure that you don’t pull the

indicator chain out of the deflection

pulley (4).

Check:

• Place shifter in gear position "1" while

moving the crank.

• Setting too loose: In gear position "1" the

tension chain can be pulled out of the

deflection pulley by hand.

• Setting too tight: It is difficult to place

the shift lever in gear position "1".

• If required, readjust the shift mechanism

(in third gear).

CONNECTING DRUM BRAKE

Caution:

Only use brake levers with a cable

moving distance of at least 15 mm and a

leverage of “i“ = 3.8 – 4.2 (Fig. 10).

• Fit cable stop (1, Fig. 11) with adjusting

bolt (2) and nut (3) and insert into the slot

on the brake anchor plate.

• Turn adjusting bolt down by approx.

2

/

3

and route the brake cable from the

brake handle.

• Push lower brake cable end through

adjusting bolt (2) and insert lower cable

housing end into adjusting bolt.

• Thread brake cable end (4) into

fork unit (5).

• Tighten screw (6) slightly.

• Attach fork unit to brake lever (7).

• Pull brake cable end taut with pliers

so that fork unit can still be attached and

removed (important for changing wheel).

• Tighten screw (6).

Caution:

For NL version drum brake hub with

special lever (8), only use original NL

brake cable (fork unit (5) is not suitable).

ADJUSTMENT DRUM BRAKE

• Unscrew adjusting screw (2, Fig. 11)

until the brake pads drag lightly.

• Actuate the hand brake lever forcefully

several times and then, if necessary,

turn the adjusting screw further in just

until the wheel starts spinning freely.

• Lock hex nut (3).

Caution:

Check that all the brake system

components are functioning properly!

10

7

8

11

9

2

1

3

min.

13 mm

min. 90 mm

4

5

min. 12 mm

max. 30°

1

2

3

2.5 mm

1.7 Nm

15 in.lbs.

8

5

7

6

4

132

a

i =

l

—

a

25

l

Loading...

Loading...