6

DUALDRIVE

ASSEMBLY

Technical Manual 2006

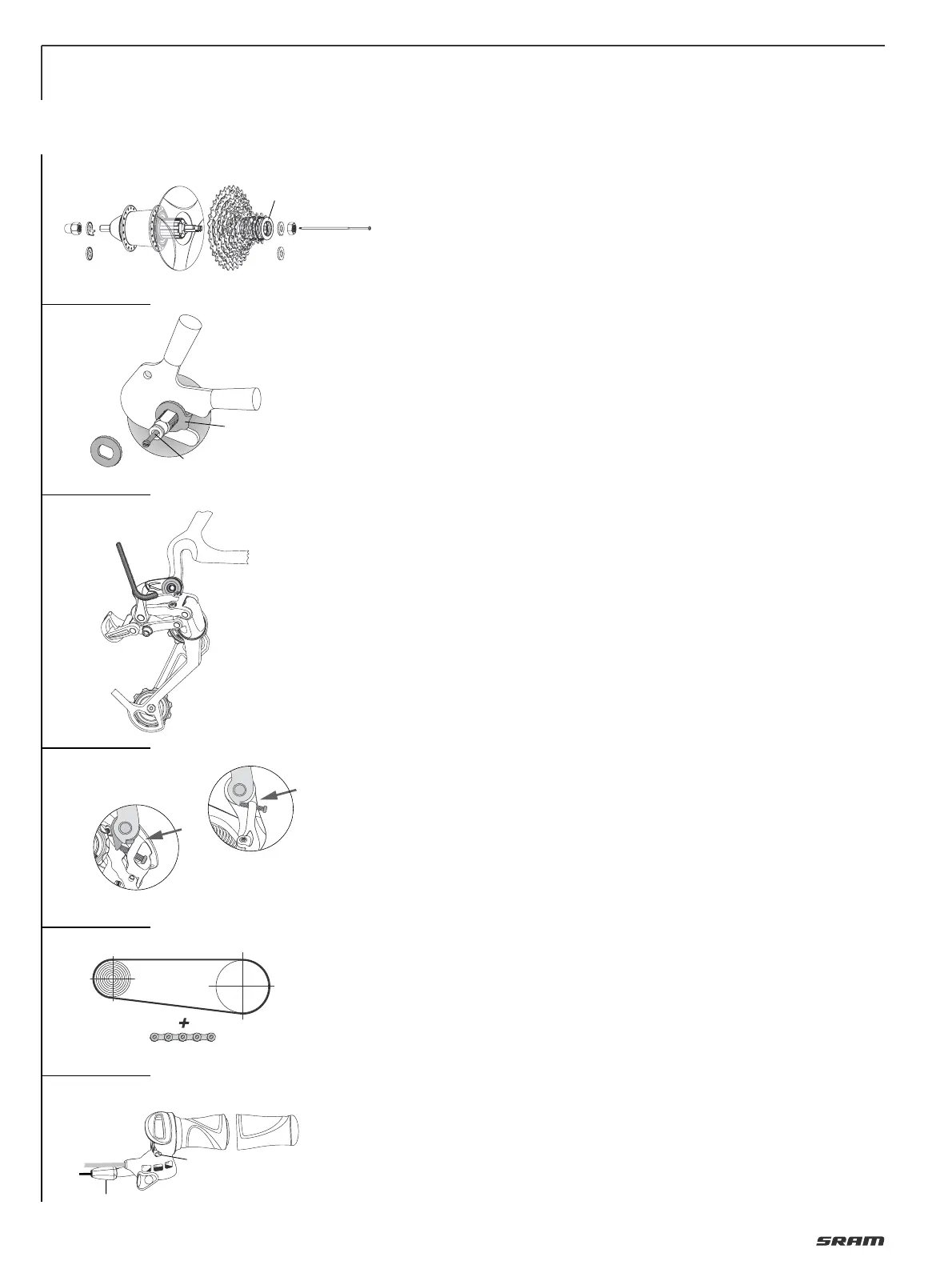

ASSEMBLY HUB

• Lace the wheel as normal.

• Place spoke protector disc (1, Fig. 1) on

shoulder of hub, fit cassette (2) onto

driver profile. Screw lock nut (3) with

cassette tool (Park Tool FR-5 or SRAM

Part No. 4624 411 010), tightening torque:

40 Nm (350 in.lbs.).

• Screw shifting rod (1, Fig. 2) into the hub

axle and tighten it with 0.2 Nm (1.8 in.lbs.).

• Fit wheel in dropouts.

• Place retaining washers (Fig. 2) on both

sides of the axle – the serrations must

bear against the dropout.

– Version for horizontal dropouts (2): the

lug must engage in the dropout slot.

– Version for vertical dropouts (3):

without lug.

• Tighten up axle nuts. Tightening

torque 30 – 40 Nm (266 – 350 in.lbs.).

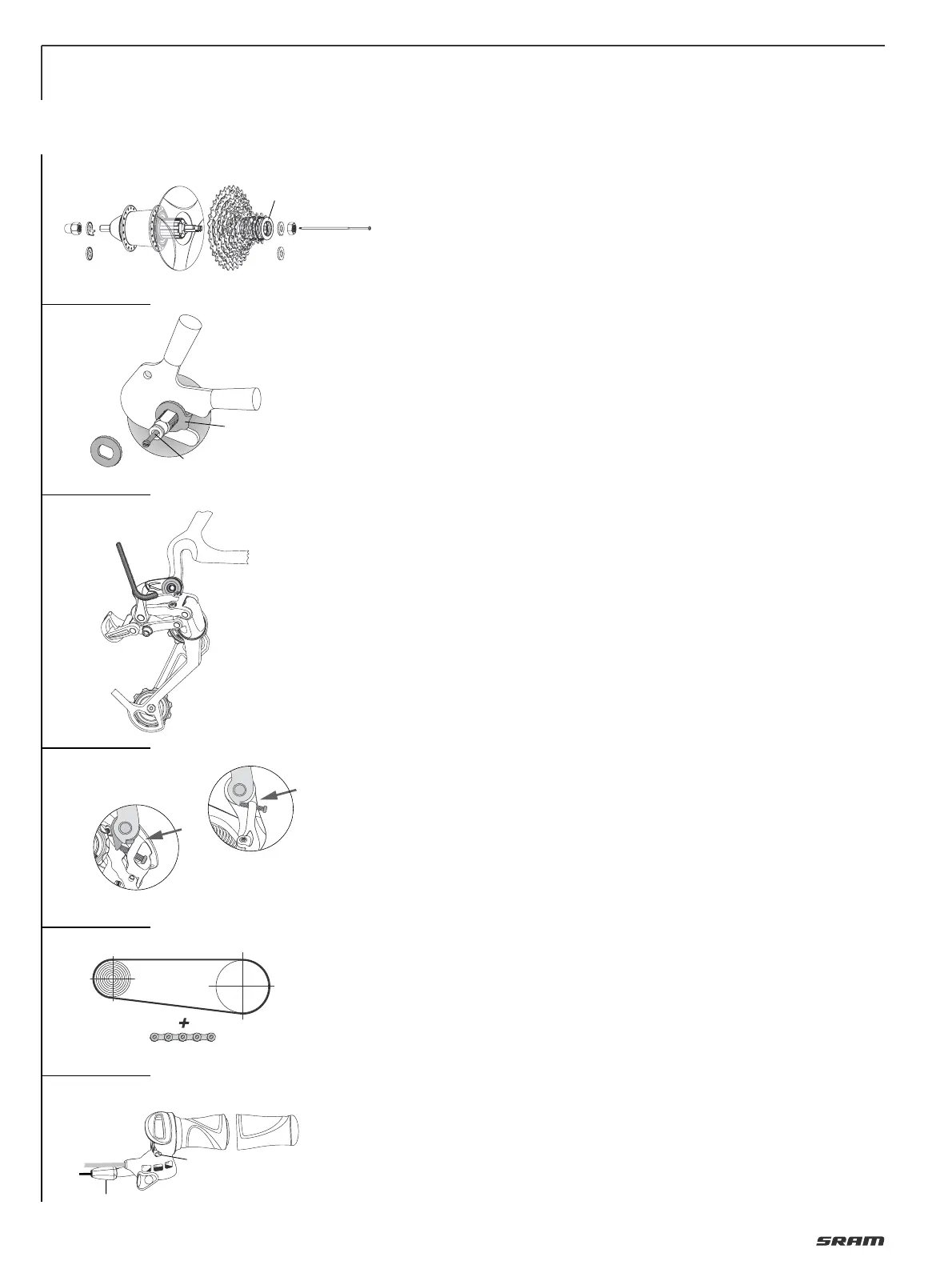

ASSEMBLY DERAILLEUR

Advice:

Check the rear derailleur hanger

alignment. A bent rear derailleur hanger

will result in inaccurate index shifting.

• Attach the rear derailleur to the frame’s

rear derailleur hanger using a 5 mm hex

head wrench (Fig. 3).

• Check that the b-adjust washer tab

(b-adjust screw at DualDrive 24) is clear

of the rear derailleur dropout tab (Fig. 4).

• Tighten the 5 mm hex hanger bolt to

8 – 10 Nm (70–85 in.lbs.).

CHAIN LENGTH

• Bypassing the rear derailleur, run the

chain around the largest cog/large

chainring combination (Fig. 5).

– For rear suspension frames, position

the rear suspension for the greatest

chain length required.

• Add 4 LINKS or 3 link + Connecting Link

to this length for proper chain length.

ASSEMBLY SHIFTER

Caution:

• Never use lubricants or solvents to

install handlebar grips. Handlebar grips

provide safety function.

For this reason, they should be

mounted in such a way as to make sure

they do not slip off handlebar!

• Always check the front and rear brake

levers for proper operation.

If there is interference between shifters

and brake levers, re-adjust lever and

shifter placement.

DualDrive single sided shifter:

• Slide the shifter (1, Fig. 6) onto the

handlebar.

• Rotate the shifter until the barrel

adjuster (4) is beneath (but out of the

way of) the brake lever.

• Tighten the 3 mm hex clamp bolt (2) to

1.9 – 2.5 Nm (17 – 22 in.lbs.).

• Slide the handlebar grip (3) onto the

handlebar.

DualDrive Trigger shifter (without picture):

• Slide shifter and brake lever onto hand-

lebar. Either component can be mounted

first, depending on personal preference.

• Slide the handlebar grip onto the

handlebar.

• Tighten the 5 mm hex clamp bolt to 5 Nm

(44 in.lbs.).

DualDrive Twist shifter (without picture):

• Slide the shifter onto the handlebar.

• Tighten the 3 mm hex clamp bolt to

1.9 Nm (17 in.lbs.).

• Slide the

plastic washer onto the hand-

lebar.

• Slide the stationary grip onto the hand-

lebar.

INSTALLING CLICKBOX

• Fit the cable and avoid small radius.

• Cable attachment points see Page 5 /

Fig. 1.

Cable housing must be movable inside

attachment.

• Place shift lever in uphill riding mode /

gear position „1“ (Fig. 7).

• Push Clickbox button down (Fig. 7).

• Push on Clickbox to the stop on the hub

axle.

• Press button up.

• Place thumb shift lever in standard

riding mode / gear position „2“ (Fig. 8).

• Match up the marks in the Clickbox

viewing window by twisting the

barrel adjuster (Fig. 8).

1

4

3

2

3

2

1

5

6

5 mm

8 – 10 Nm

70 – 85 in.lbs.

(4 Links)

DualDrive 24

DualDrive 27

2

4

1

3

1

0.2 Nm

1.8 in.lbs.

2

3

Loading...

Loading...