16

ENGLISH

5.6 PRIMING

Priming is necessary after the tool has been dismantled and prior to operating. It may also be necessary to

restore the full stroke after considerable use, if the stroke has been reduced and fasteners are not now being

fully placed by one operation of the trigger.

Oil Details

The recommended oil for priming is Hyspin® VG32 available in 0.5l (part number 07992-00002) or one gallon

containers (part number 07992-00006).

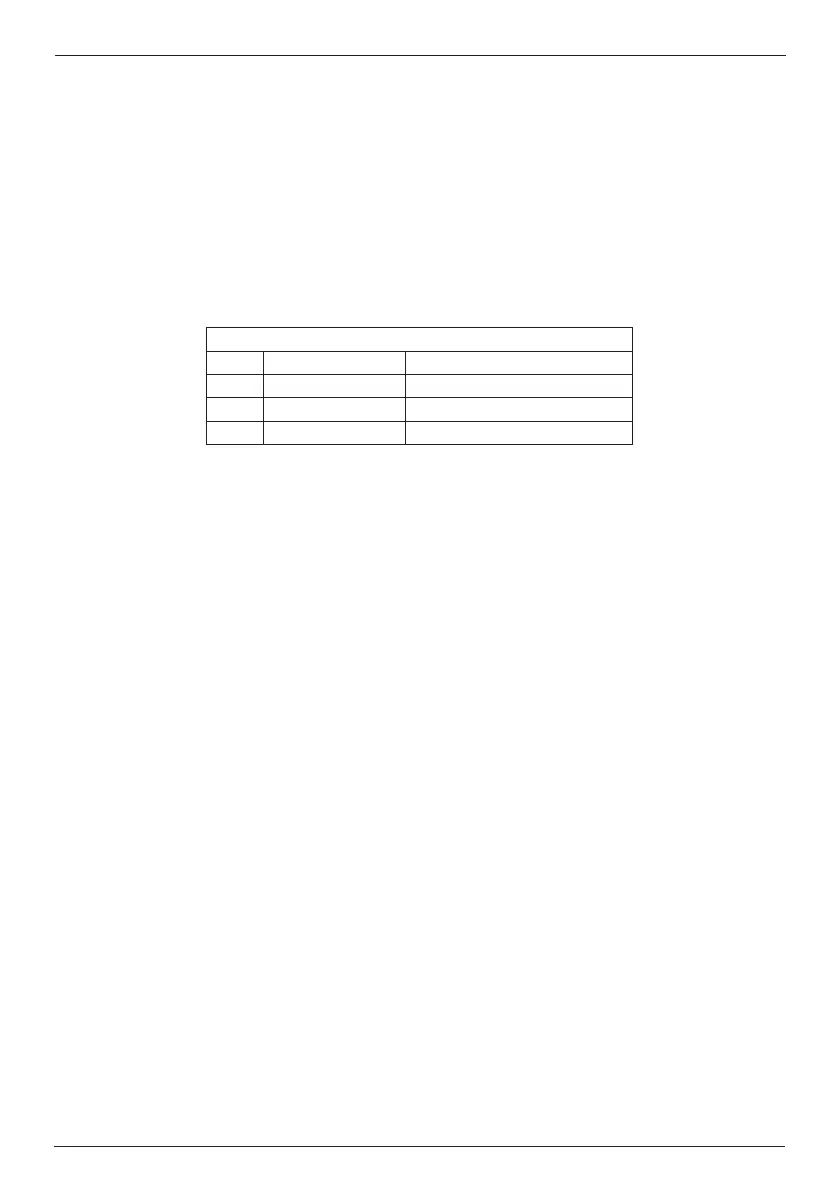

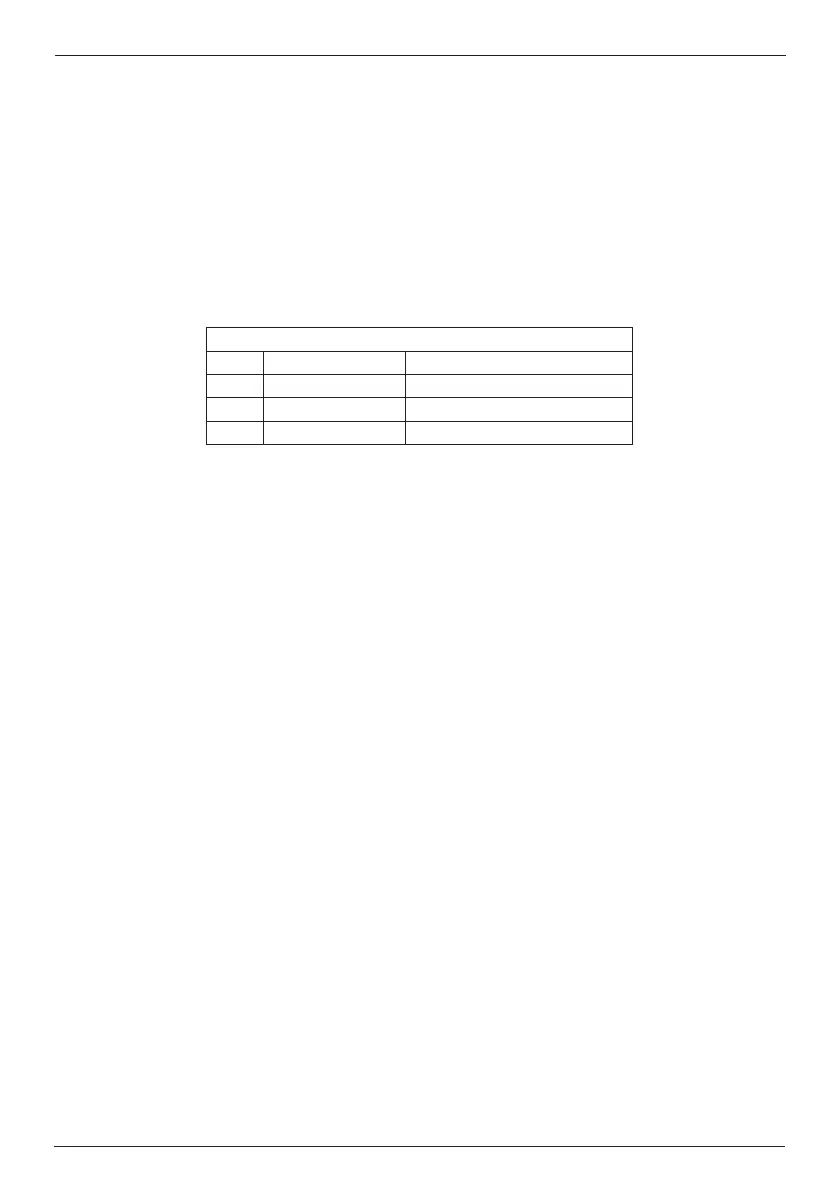

Priming Kit

To enable you to follow the priming procedure below you will need to obtain a priming kit.

Priming Kit 07900-00688

Item Part Number Description

1 07900-00351 3mm Hexagonal Wrench

2 07900-00700 Priming Pump

3 07900-00224 4mm Hexagonal Wrench

Priming Procedure

IMPORTANT - DISCONNECT THE TOOL FROM THE AIR SUPPLY OR SWITCH OFF AT ON/OFF VALVE

ASSEMBLY 7. REMOVE NOSE ASSEMBLY OR SWIVEL HEAD COMPONENTS.

All operations must be carried out on a clean bench, with clean hands in a clean area.

Ensure that the oil is perfectly clean and free from air bubbles.

Care MUST be taken at all times, to ensure that no foreign matter enters the tool, or serious damage may

result.

Before priming, empty the oil from tool as follows.

• Switch OFF air supply at ON/OFF Valve Assembly (7.)

• Remove all nose equipment (1.) Refer to section 3. 1.

• Remove Bleed Screw (4) and Bonded Seal 5.

• Invert tool over suitable container, switch ON air supply at ON/OFF Valve Assembly (7) and actuate tool.

• Residual oil in the tools hydraulic system will empty through bleed screw orice.

CARE SHALL BE TAKEN TO ENSURE THAT THE BLEED HOLE IS NOT DIRECTED TOWARDS THE OPERATOR

OR OTHER PERSONNEL.

• Switch air supply OFF at ON/OFF Valve (7.)

• Screw priming pump (07900-00700) into bleed screw port, utilizing Seal (5.)

• Actuate Priming Pump by pressing down and releasing several times until resistance is evident and the

Head Piston starts to move rearward.

ENSURE PUMP IS KEPT ‘SQUARE’ TO BLEED SCREW PORT DURING PRIMING OPERATION TO PREVENT

BREAKAGE OF BLEED NIPPLE ON PRIMING PUMP.

• Remove the priming pump, surplus oil will expel from bleed screw port.

• Replace the Bleed Screw 4 together with Bonded Seal (5).

• Switch ON air supply at ON/OFF Valve Assembly (7).

• Check that the stroke of the head piston reaches specication. If not repeat above procedure.

• Switch OFF air supply and ret nose equipment. Refer to section 3.1.

• Check that the stroke of the tool meets the minimum specication of 26 mm.

Loading...

Loading...