Do you have a question about the Steris AMSCO 600 Medium 639V-3 and is the answer not in the manual?

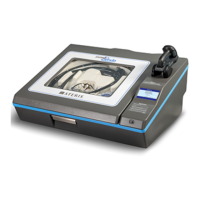

| Category | Laboratory Equipment |

|---|---|

| Type | Steam Sterilizer |

| Model | AMSCO 600 Medium 639V-3 |

| Manufacturer | Steris |

| Chamber Dimensions | 16 x 16 x 26 in (406 x 406 x 660 mm) |

| Chamber Volume | 6.8 cu ft (193 L) |

| Sterilization Temperature Range | 250°F to 275°F (121°C to 135°C) |

| Sterilization Pressure Range | 20 to 30 psig (138 to 207 kPa) |

| Power Supply | 208-240 VAC, 60 Hz, Single Phase |

| Power Consumption | 4.5 kW |

| Dimensions (WxDxH) | 28 x 38 x 68 in (711 x 965 x 1727 mm) |

| Weight | 650 lbs (295 kg) |

Explains door lock, pressure relief, and obstruction switch safety features.

Describes the sterilizer's purpose for healthcare facilities and microbicidal activity.

Lists design parameters including dimensions, weights, and associated publications.

Details operating temperature, humidity, altitude, and IP rating.

Guidelines for disposing of waste materials like paper, filters, water, and electronic equipment.

Explains symbols used on equipment labels and control display screens.

Outlines essential warnings and cautions for operating and servicing the sterilizer.

Provides a labeled diagram of major sterilizer components with a legend.

Details the control panel on the operating end, including touch screen and buttons.

Describes the water pump, pressure vessel, and power supply for the steam generator.

Explains the operation and types of screens on the sterilizer's touch screen interface.

Explains the function and use of the emergency stop switch for immediate system shutdown.

Outlines physical parameters, chemical indicators, and vacuum leak tests for monitoring performance.

Guidelines for properly loading and arranging items in the sterilizer chamber for effective sterilization.

Procedures for loading and securing the loading car and transfer carriage.

Details the parameters and use of prevac cycles for sterilizing wrapped goods.

Instructions on how to safely end a cycle prematurely if needed.

Guides on selecting cycles and customizing parameters like temperature, time, and dry time.

Explains the purpose and procedure for running Warm-Up, Bowie-Dick, Vacuum Leak, and Air Detector tests.

Information on scheduled maintenance, service requirements, and contractor responsibilities.

Daily procedure for cleaning the chamber drain strainer to ensure proper function.

Outlines procedures for cleaning the chamber, stainless-steel surfaces, and touch screen.

Lists recommended spare parts and procedures for ordering them.

General overview of alarm conditions, screens, and printouts.

Describes the "Air Detected in Drain" alarm and troubleshooting steps.

Addresses issues when Bowie-Dick or DART tests fail, including causes and solutions.

Troubleshooting for erratic door movement, including debris and air pressure.

Information on the "Emergency Stop Pressed OE Door" alarm and how to reset it.

Addresses alarms related to failures in reading chamber pressure.

Troubleshooting for steam generator pressure build-up issues.

Explains the leak test failure alarm and corrective actions.

Addresses alarms when the non-operating end door is obstructed during closing.

Explains alarms for chamber temperature being below the programmed sterilize temperature.

Detailed steps for safely opening the chamber door in emergencies.