10

4.4 Electrical installation

Permission must be obtained from your local power supply utility.

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

WARNING Electrocution

The appliance contains inverters (e.g. variable speed

compressors, high efficiency circulation pumps or high

efficiency fans). In the event of a fault, inverters can

cause DC residual currents. If RCDs are provided, they

have to be type B AC/DC-sensitive.

A DC residual current can block type A RCDs.

Ensure that the appliance power supply is discon-

nected from the distribution board.

Electrical data is provided in the chapter „Specification/ Data

table“.

All electrical connection and installation work must be carried out

in accordance with VDE regulations (DIN VDE 0100) [or local regu-

lations], the rules of your local power supply utility, and relevant

national and local regulations.

The cable cross-section must be designed for the maximum pos-

sible operating current of the appliance (see „Specification/Data

table“).

Note

Route the power cables and control cables separately.

Note

Provide separate fuses for the power circuits for the ap-

pliance, the electric emergency/booster heater and the

control unit.

4.5 Oxygen diffusion

!

Material losses

Do not use open vented heating systems. Use oxygen

diffusion-proof pipes in underfloor heating systems with

plastic pipework.

In underfloor heating systems containing permeable plastic pipes,

or in open vented heating systems, oxygen diffusion can cause

corrosion to the steel components of the indirect coil in the DHW

cylinder, steel radiators or steel pipes.

!

Material losses

The products of corrosion (e.g. rusty sludge) can sett-

le in the heating system components, which may result

in a lower output or fault shutdowns due to reduced

cross-sections.

4.6 Transport

!

Material losses

If the appliance is transported without packing and wit-

hout using a pallet, its outer casing may be damaged.

Remove the side panels and doors in such cases.

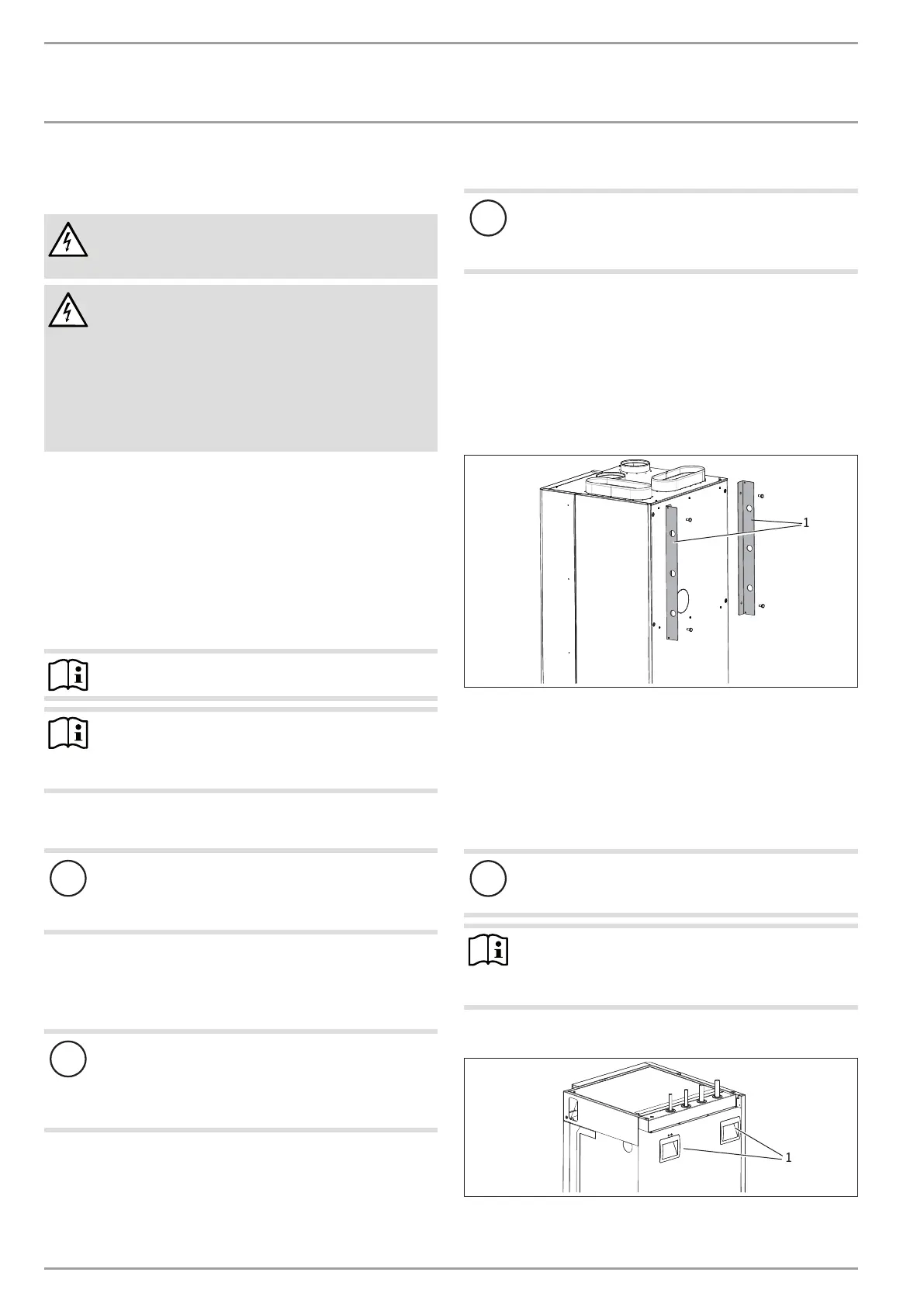

4.6.1 Function module

To protect the appliance against damage, transport it vertically

inside its packaging. Where space is restricted, you can also tilt

the appliance at an angle to move it.

To make handling easier, you may attach a transport aid on the

back of the function module. This comprises two angled brackets.

Fit one angle bracket each vertically on the l.h. and r.h. side.

26_04_01_0620_

1

1 Transport aid

Slide a robust pipe through the holes inside the transport

aids to create a handle.

The transport aid can also be used in connection with a

crane/hoist to transport the appliance to the installation

location.

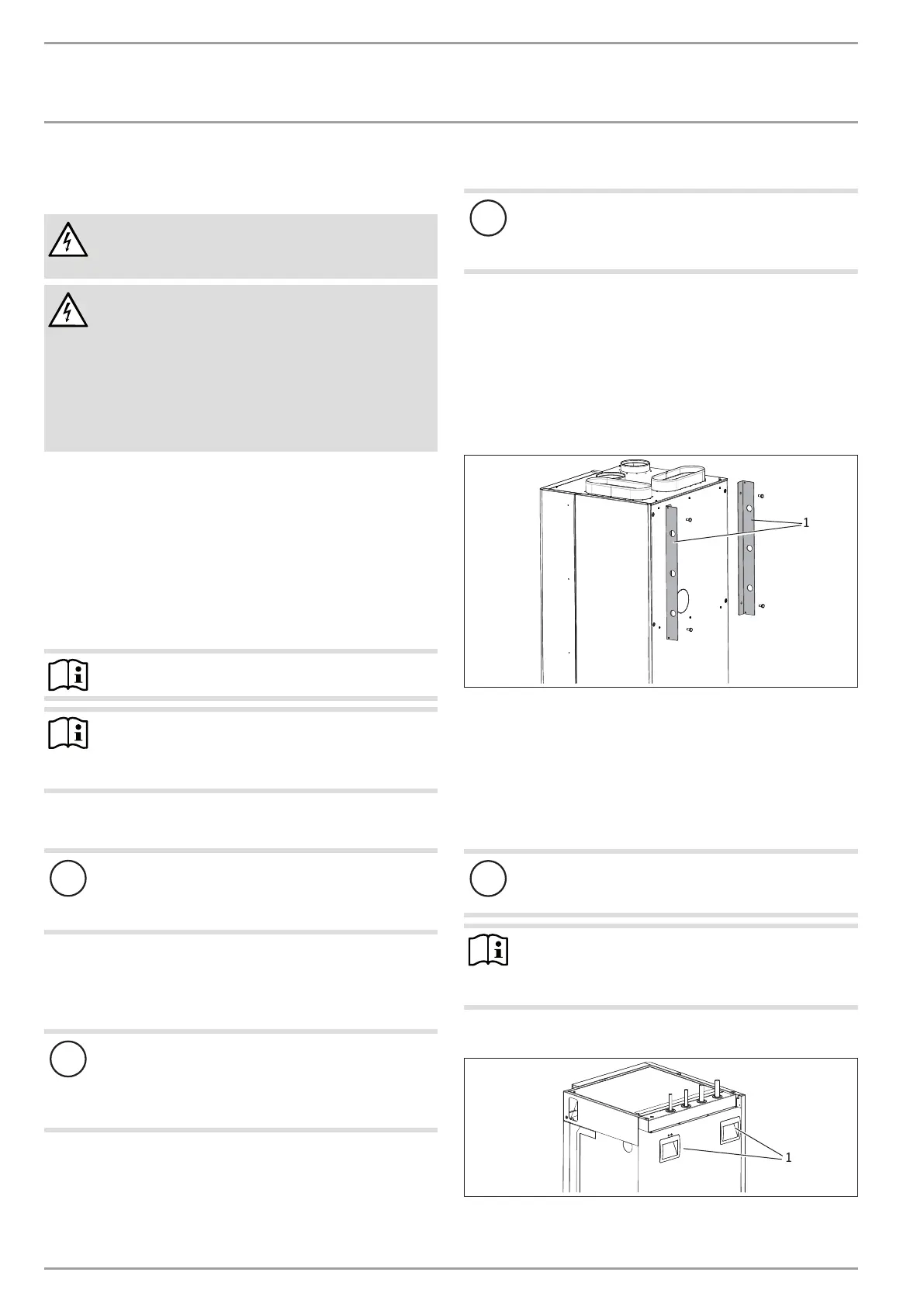

4.6.2 Cylinder module

!

Material losses

During transport, never hold the cylinder module by its

connection pipes, as these would bend out of shape.

Note

We recommend the transport of the cylinder module on

its pallet to the installation location. The pallet offers

more places to hold than the cylinder module casing.

There are two grip recesses at the top of the back panel.

1

D0000075609

1 Recessed grips

Loading...

Loading...