14

Pushing the cylinder module towards the function module

Push the cylinder module carefully towards the function

module, so that the rear r.h. adjustable foot of the cylinder

module is near the recess in the joining bracket.

5.3 Connecting modules

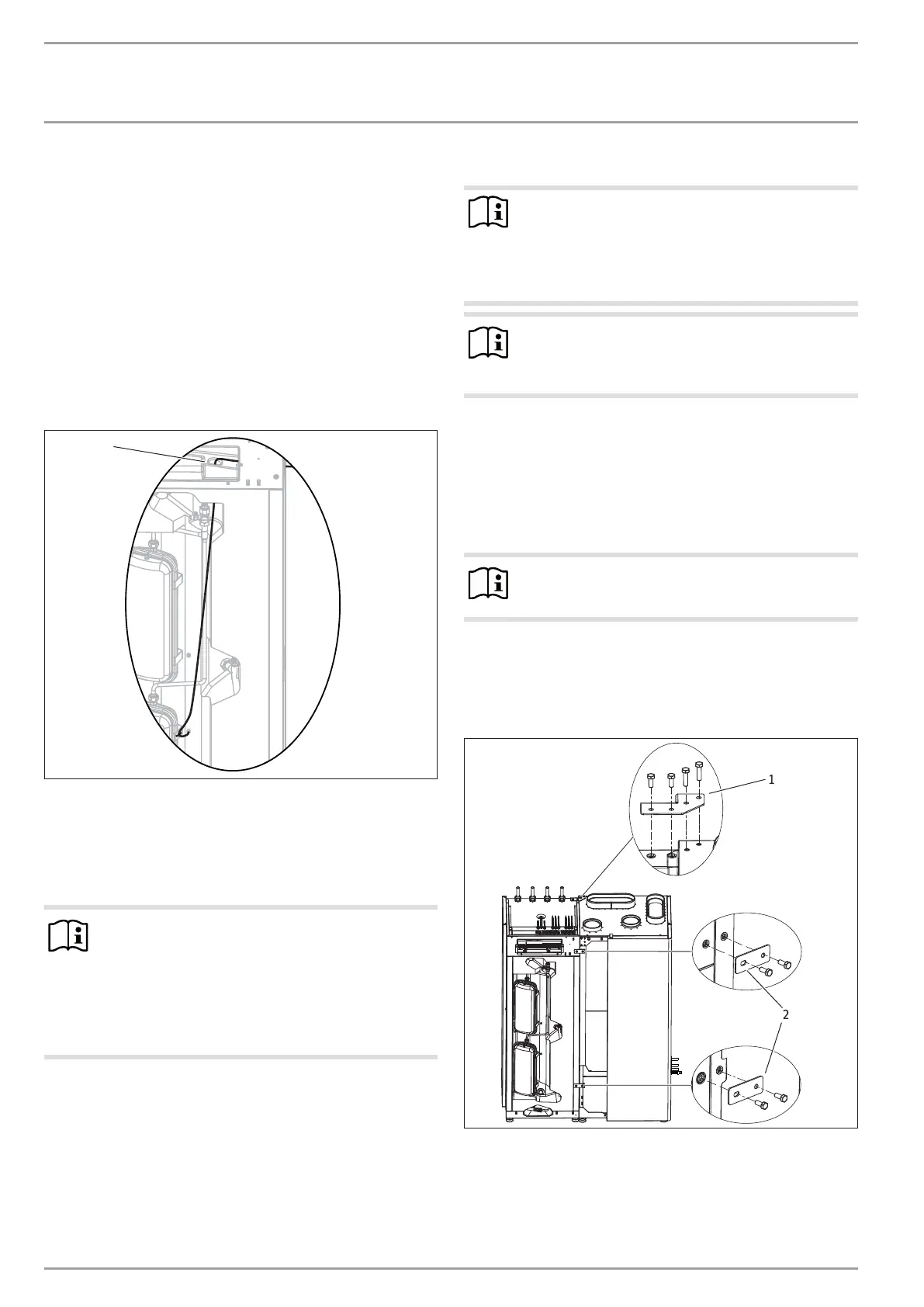

Cylinder temperature sensor and anode cable

Remove the cable tie that tie together the electrical cables

of the anode terminal and the cylinder temperature sensor

lead.

Pull the connecting cables/leads of the anode and the cylin-

der temperature sensor through the aperture located on the

top r.h. side in the cylinder module.

1

26_04_01_0556

1 Aperture in the thermal insulation for sensor lead of the cy-

linder temperature sensor

Push the cylinder temperature sensor from the top through

the aperture in the thermal insulation.

Insert the cylinder temperature sensor into the lower cylin-

der sensor well.

Note

It is possible that the cylinder module and the function

module will still be too far apart to be able to insert the

cylinder temperature sensor into the sensor sleeve.

If so, you can insert the cylinder temperature sensor into

the sleeve at a later point. What is important is that you

route the sensor lead through the insulation before you

install the terminal bracket.

The top sensor sleeve is required either in connection with buffer

operation on convector heaters (see chapter „Settings/ DHW/

DHW buffer mode“) or for economy mode (see chapter „Connec-

ting internal cables“).

Pushing the cylinder and the function modules together

Note

An air hose to capture the differential pressure runs

along the l.h. side of the function module. This air hose

must run inside the curved groove cut into the thermal

insulation.

Ensure that this air hose is seated correctly.

Note

The adjustable feet must not be fully screwed in, other-

wise you will not be able to push the joining bracket

between the bottom panel and the foot.

Push the cylinder module further towards the function mo-

dule, so that the rear r.h. adjustable foot of the cylinder mo-

dule is pushed into the recess in the joining bracket.

The lower joining bracket ensures that the cylinder module is

automatically pushed into its final position.

Level the cylinder module and the function module vertically

to the same height by turning the adjustable feet.

Note

The cylinder module drops 4 to 5mm when its cylinder

is filled.

Turning anti-clockwise exposes more of the adjustable feet, mea-

ning the appliance moves upwards. The cylinder module must be

snug against the function module.

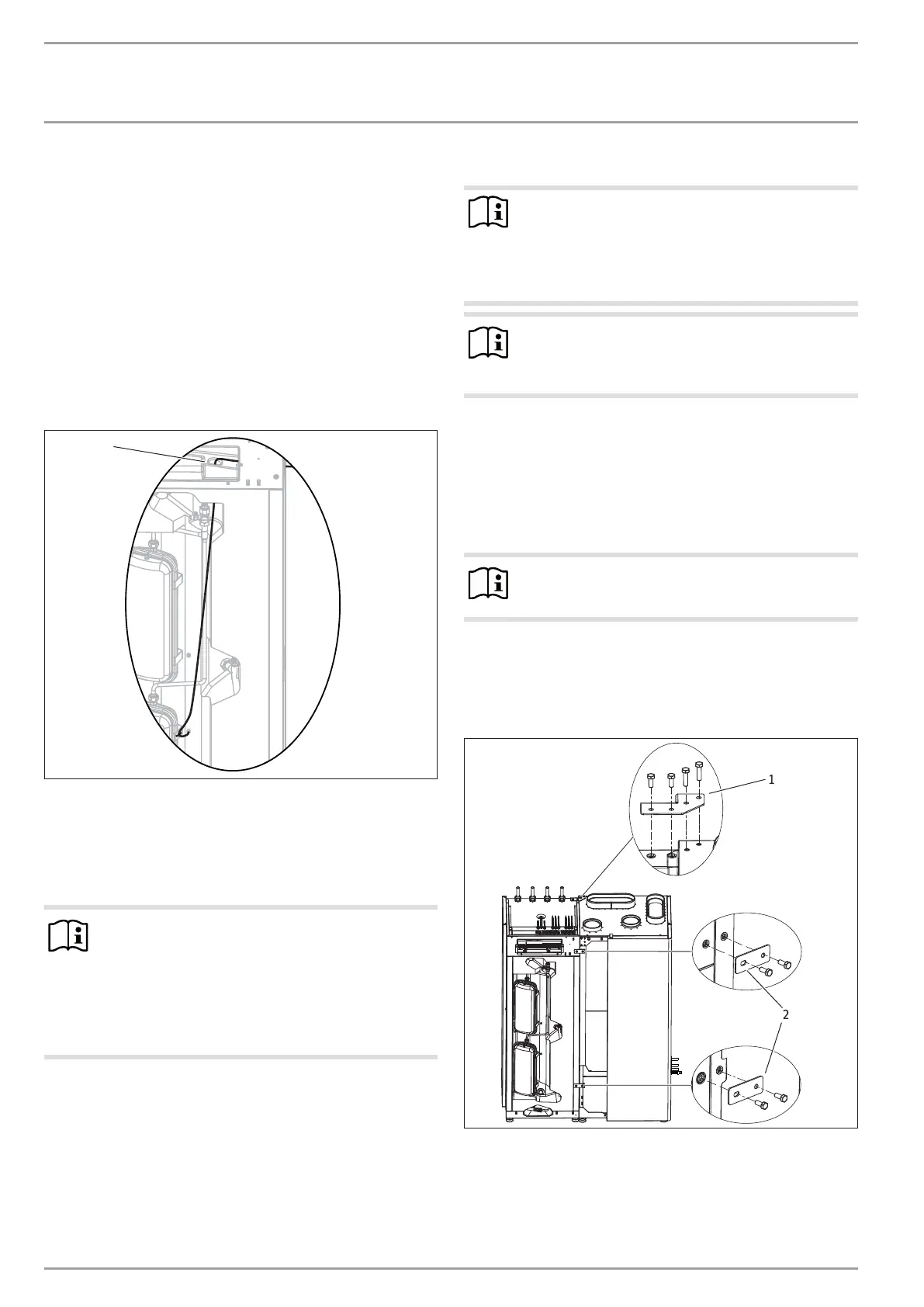

Connection top back

D0000076677

1

2

1 Joining plate

2 Horizontal locking bracket

Connect the function module and the cylinder module at

the top back by positioning joining plate and inserting two

screws each through the joining plate into the function mo-

dule and the cylinder module.

Loading...

Loading...