23

Refit the protective caps on the fill valves.

Determine the fill pressure

Volume of the diaphragm expansion vessels integrated into the

appliance

l 15

Expansion vessel pre-charge pressure ( P0 ) bar 0.75

If the height difference ∆h between the highest point of the heating

system and the diaphragm expansion vessel is no more than 6m,

the diaphragm expansion vessel can be used without any changes

being required.

Fill the heating system to a pressure of at least 1.1bar

(P0+0.3bar). Observe the safety valve‘s response pressure

of 3bar.

If the height difference between the highest point of the heating

system and the diaphragm expansion vessel is more than 6m, the

pre-charge pressure needs to be adapted.

Calculate the pre-charge pressure:

P0 =

∆h

10

+ 0,2 bar

D0000081230

Note that the heating system fill pressure increases

accordingly.

Check whether a further external diaphragm expansion ves-

sel needs to be installed.

Fill the heating system to the appropriate pressure

(P0+0.3bar). Observe the safety valve‘s response pressure

of 3bar.

Filling the heating system

!

Material losses

High flow rates or water hammer can damage the ap-

pliance.

Fill the appliance at a low flow rate.

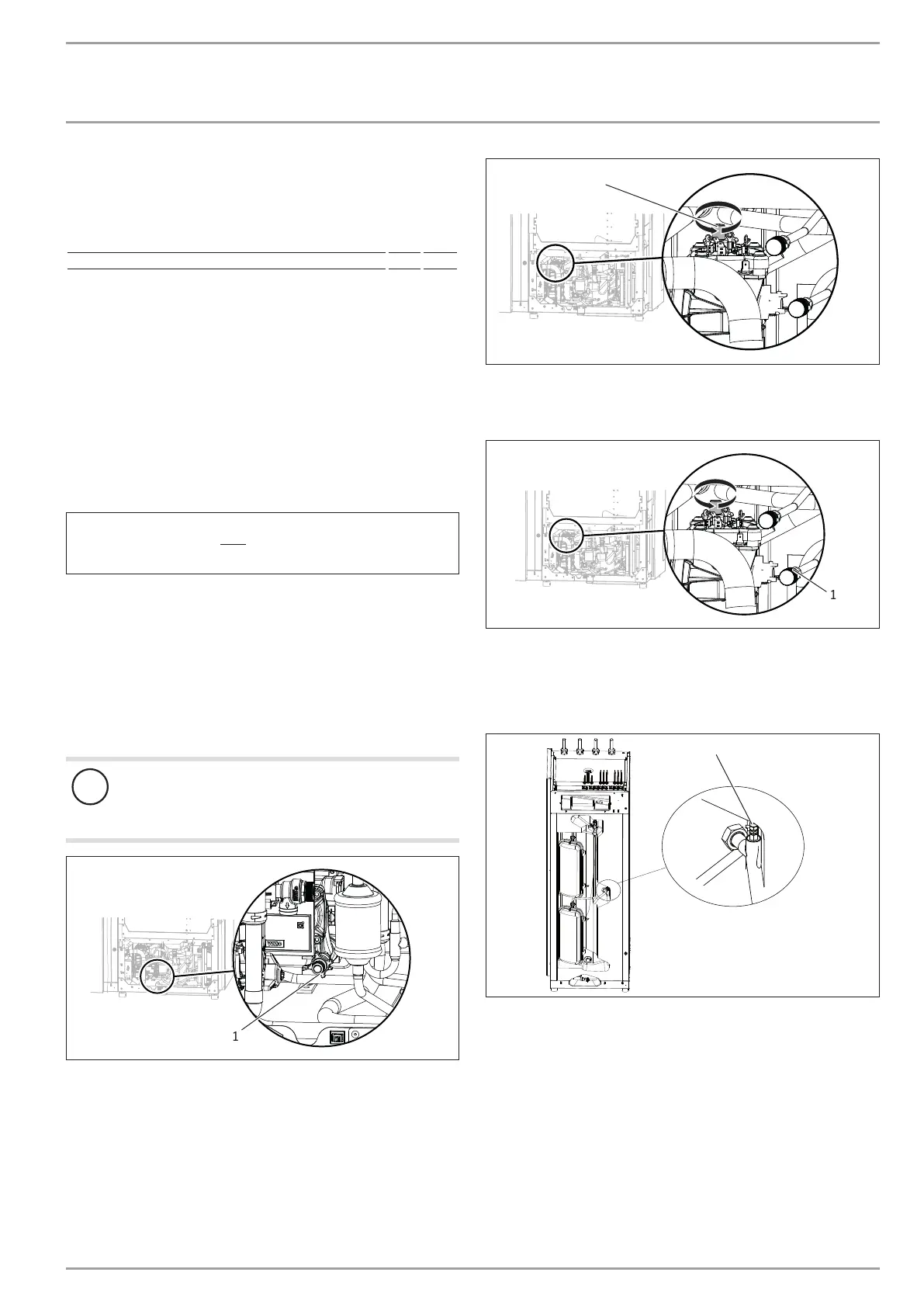

1

D0000039056

1 Drain connection for filling and draining the heating circuit

Undo the cap from the drain connection.

Connect the fill hose with a quick-action hose coupling.

Open the drain connection by turning the star grip.

1

D0000038979

1 Air vent valve on the multifunction assembly

Open the air vent valve of the multifunction assembly by

turning anti-clockwise.

D0000038979

1

1 Air vent valve on the circulation pump

Open the air vent valve on the circulation pump by pulling its

head upwards.

After venting, check whether the air vent valve of the multi-

function assembly or circulation pump drips.

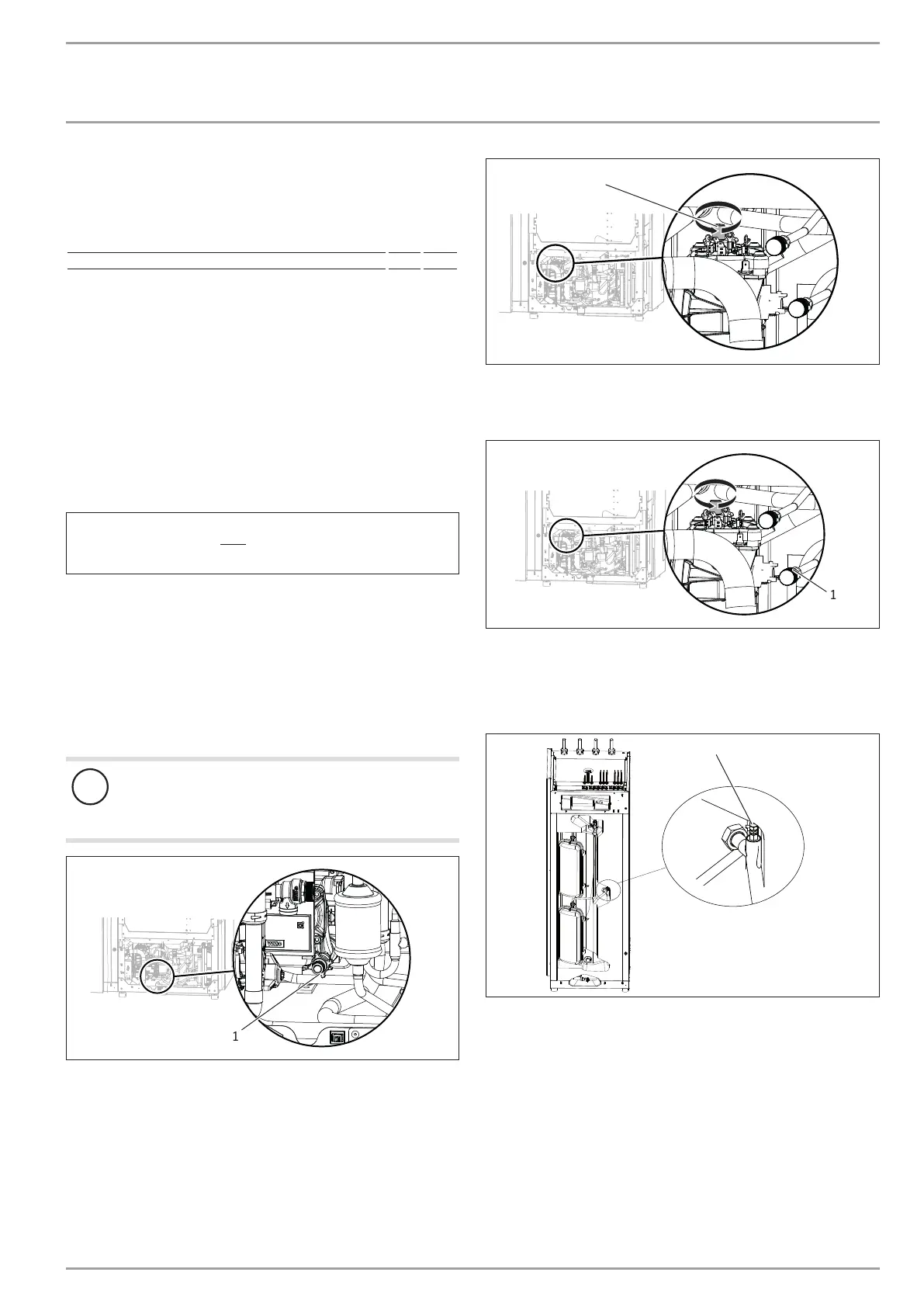

1

26_04_01_0556

1 Air vent valve of the DHW heating line

Open the air vent valve of the DHW heating line.

For filling, turn the lever on the drain connection 90°

anti-clockwise.

Switch on the appliance and set the displayed system

pressure at the programming unit („PRESSURE HTG CIRC“

parameter).

Fill the system.

After filling close the drain connection.

Fit the cap on the drain connection.

You can check the water pressure in the heating circuit on the

programming unit with the „PRESSURE HTG CIRC“ value.

Loading...

Loading...