FS 260 C, FS 360 C

English

38

N Check electrode gap (A) and

readjust if necessary – see

"Specifications".

N Use only resistor type spark plugs of

the approved range.

Rectify problems which have caused

fouling of spark plug:

N Too much oil in fuel mix.

N Dirty air filter.

N Unfavorable running conditions,

e.g. operating at part load.

Fit a new spark plug after approx. 100

operating hours or earlier if the

electrodes are badly eroded.

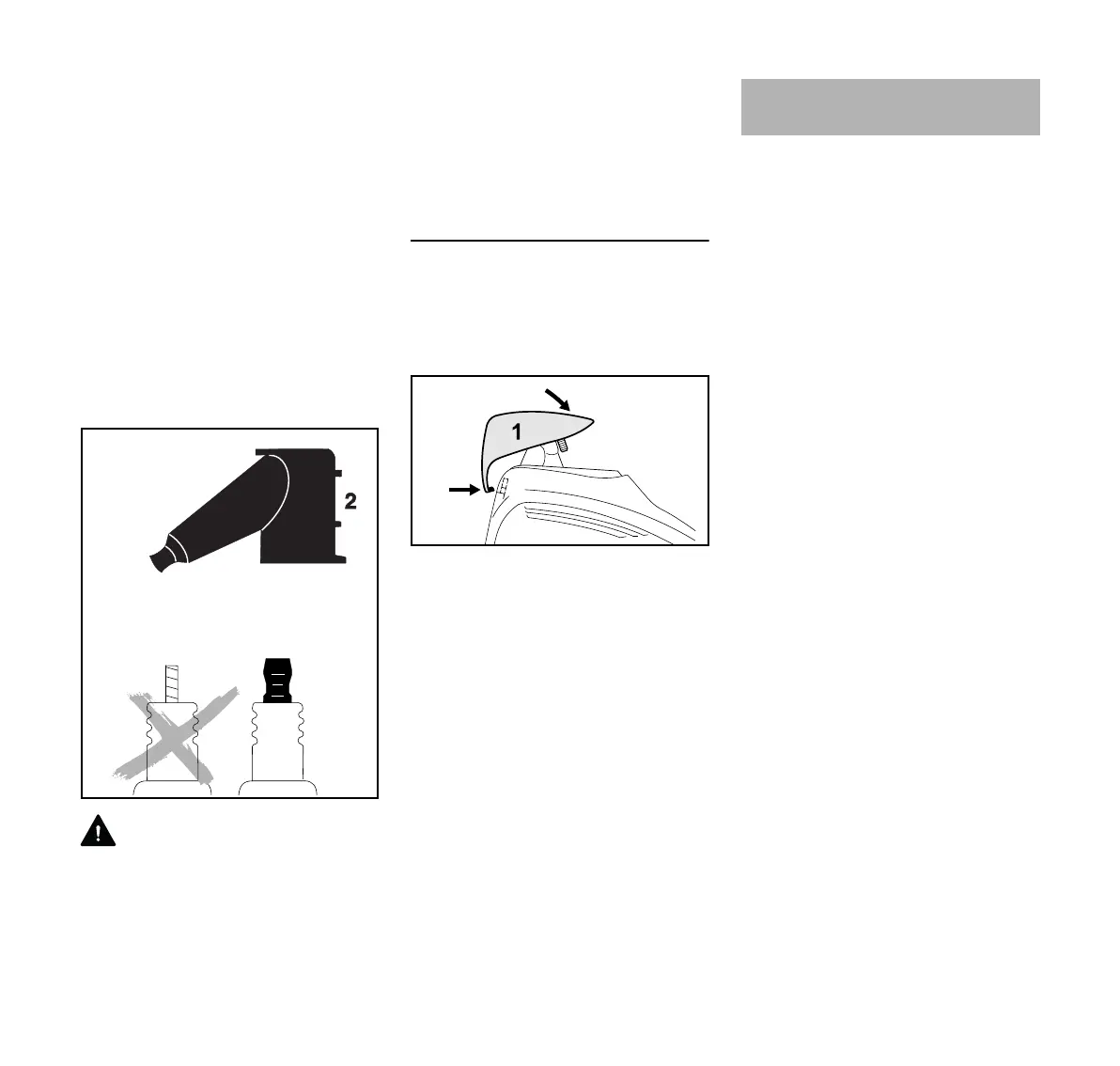

WARNING

To reduce the risk of fire and burn injury,

use only spark plugs authorized by

STIHL. Always press spark plug boot (2)

snugly onto spark plug terminal (1) of the

proper size. (Note: If terminal has

detachable SAE adapter nut, it must be

attached.) A loose connection between

spark plug boot and ignition wire

connector in the boot may create arcing

that could ignite combustible fumes and

cause a fire.

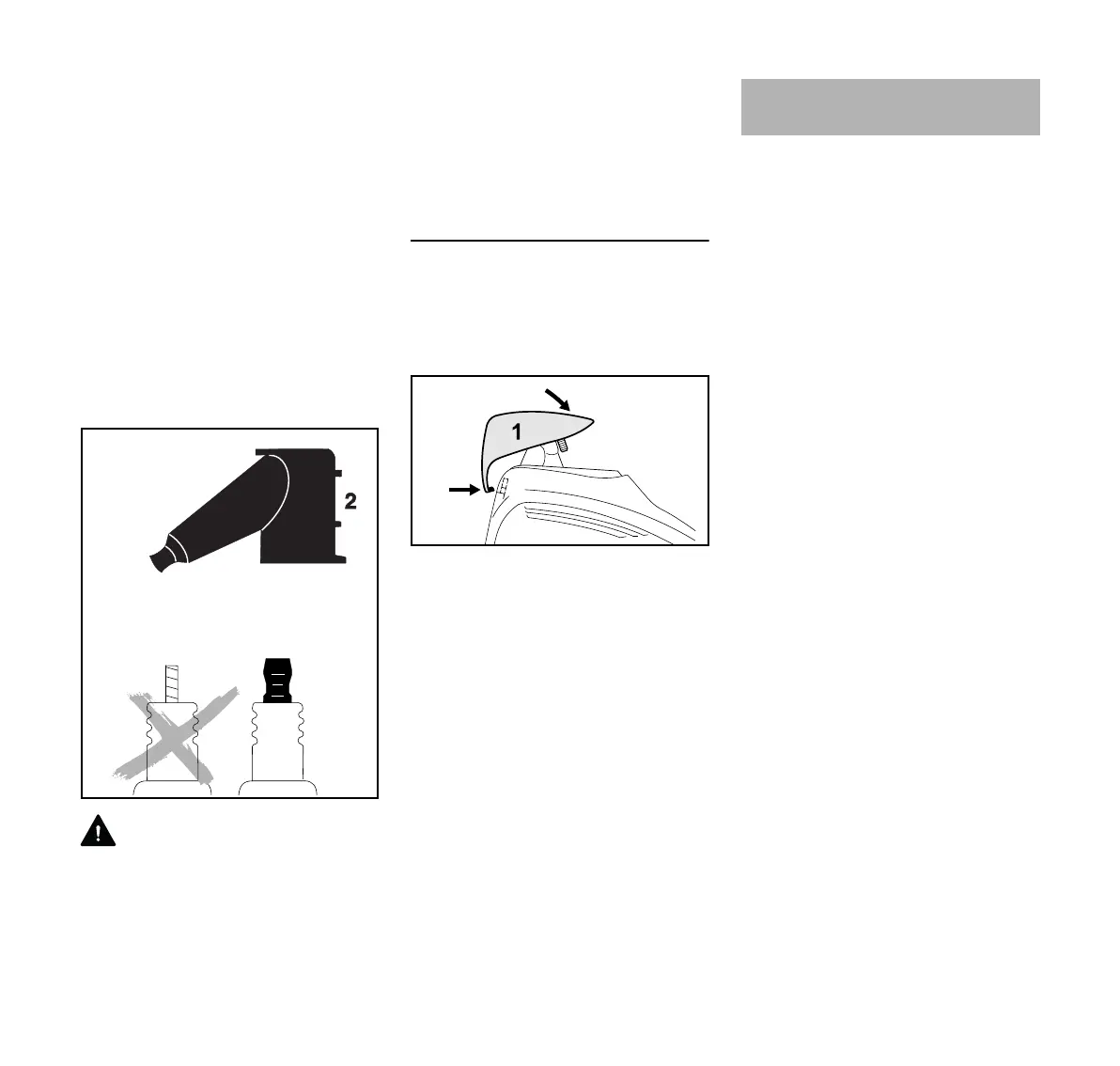

Installing the Spark Plug

N Screw the spark plug into the

cylinder.

N Press the spark plug boot firmly

onto the spark plug.

N Fit the cap (1) on the shroud from

the rear and push the lug (2) into the

opening (3) in the shroud at the

same time.

N Swing the cap forwards onto the

shroud, insert and tighten down the

screw (4) firmly.

If engine running behavior is still

unsatisfactory after the air filter has been

serviced and the carburetor and throttle

cable have been adjusted correctly, the

cause may also be in the muffler.

Have the muffler checked for

contamination (coking) by a servicing

dealer!

STIHL recommends that maintenance

and repair work be carried out only by

authorized STIHL dealers.

Engine Running Behavior

Loading...

Loading...