45MS 650, MS 660

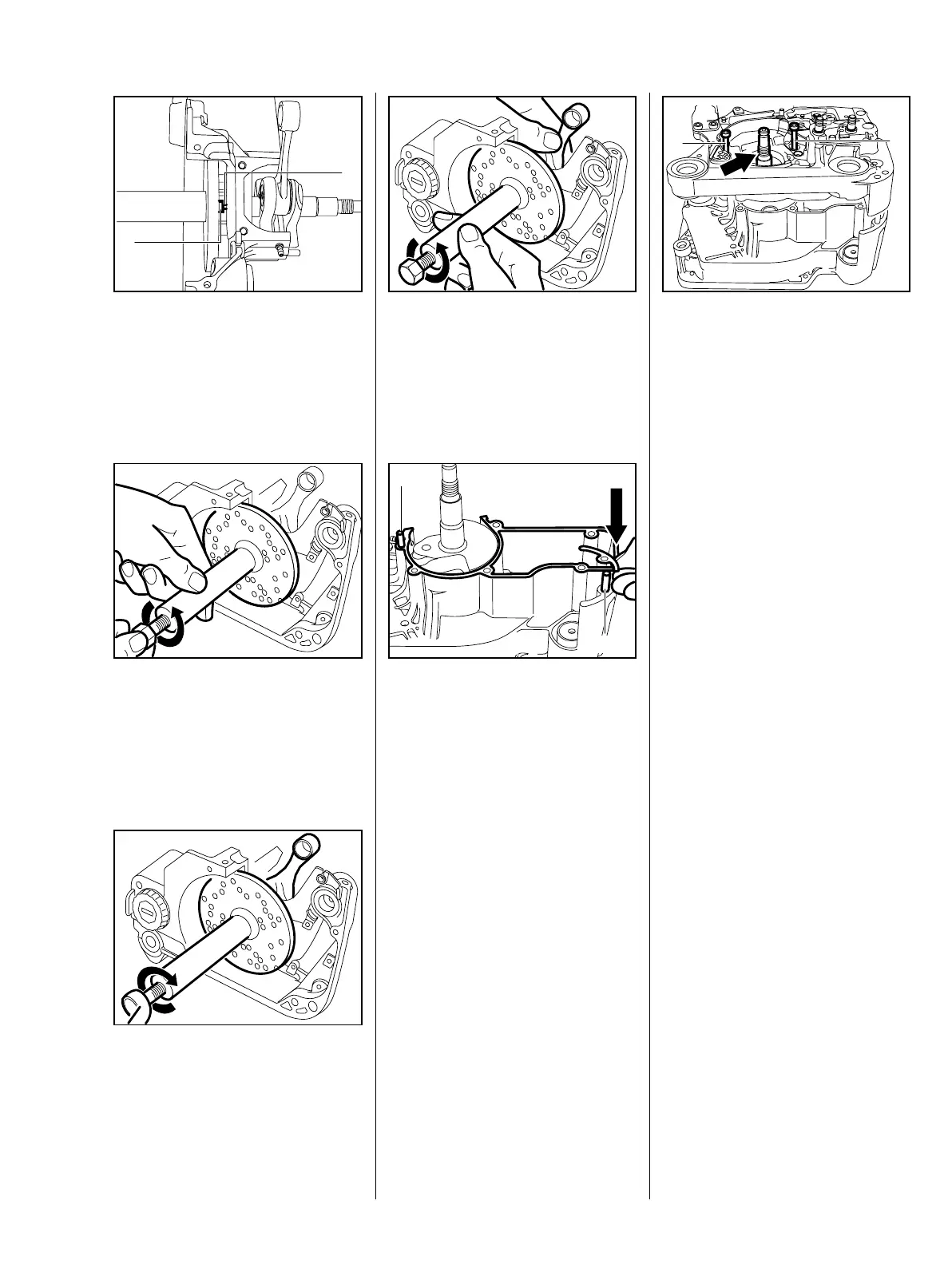

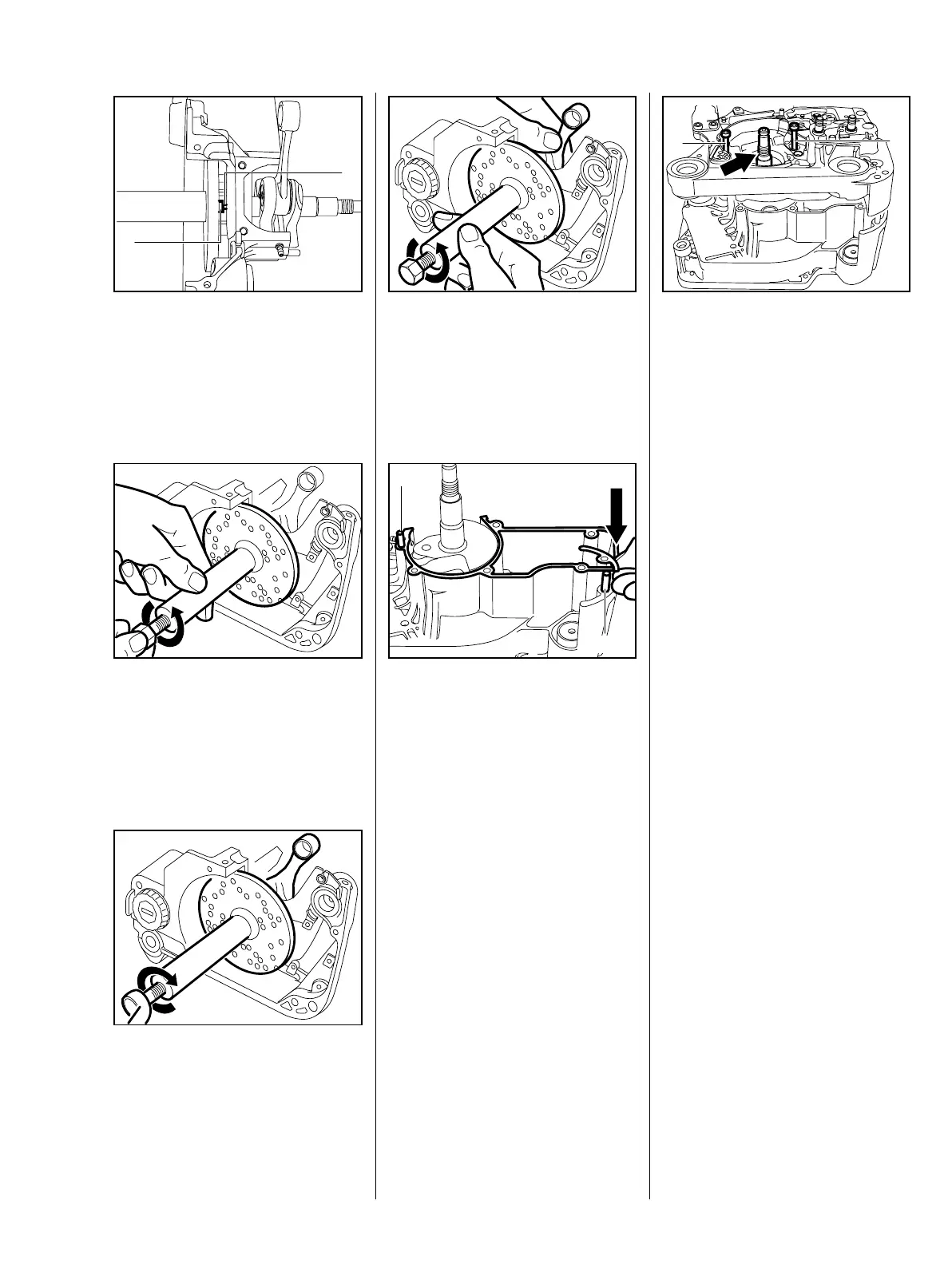

: Screw threaded sleeve (2) to

thread (1) of crankshaft stub.

178RA217

2

1

VA

: Hold the spindle steady and

rotate the service tool counter-

clockwise until the drilled plate

butts against the crankcase.

178RA218

VA

: Turn the spindle clockwise until

the crankshaft locates against

the ball bearing.

The connecting rod must point

toward the cylinder flange while the

crankshaft is being installed.

178RA219

VA

: Hold the crankshaft steady,

release the spindle counter-

clockwise and then unscrew the

service tool, also counter-

clockwise.

178RA220

VA

: Place new gasket (arrow) on the

flywheel side of the crankcase.

: The gasket is held in position by

the pins (1).

– Fit bar mounting studs at clutch

side – b 5.7

178RA221

VA

1

1

– Lubricate straight stub of

crankshaft (arrow) with oil.

– Fit crankshaft stub in the ball

bearing.

: To prevent the crankcase halves

and gasket twisting, fit M5x72

178RA222

1

1

VA

screws (arrows) in two crankcase

holes and tighten them down as

far as stop.

Loading...

Loading...