7 QZ 70 en40 | Quartz

StoneL publication 105406revA

4.7 Expeditors

4.7.1 Operation sequences

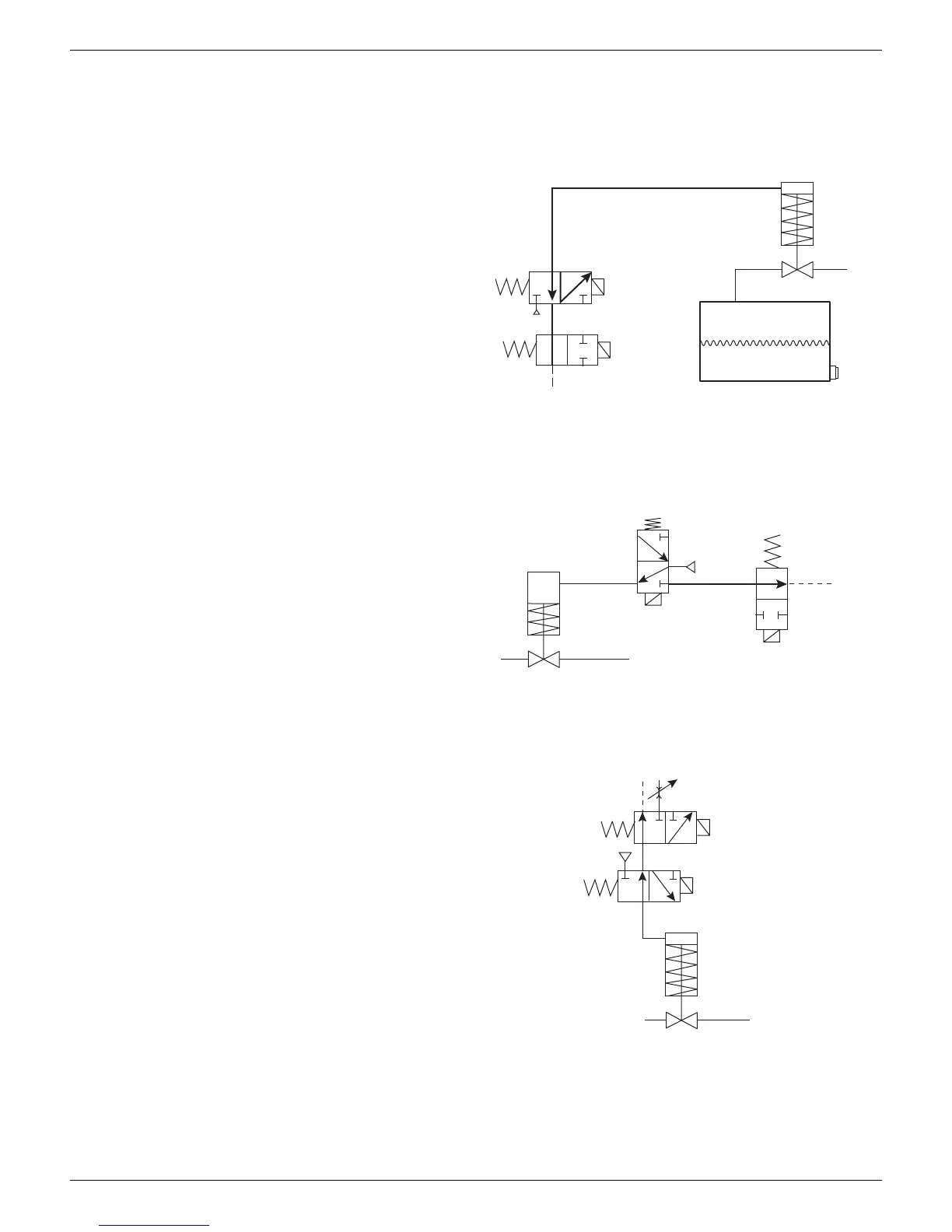

Fill control operation sequence (Fig. 1)

1. Fill

• Low level indicated

• Controller energizes primary solenoid

• Actuator/valve opens

• Open switch activates

2. Top o

• Intermediate high level indicated

• Controller de-energizes primary solenoid and controller

energizes secondary solenoid

• Actuator/valve closes

• Intermediate switch activates

• Secondary solenoid energizes

• Actuator/valve stops at pre-set intermediate position

3. Full

• Full level indicated

• Controller de-energizes secondary solenoid

• Actuator/valve closes

• Closed switch activates

Emergency shut down (ESD) operation sequence (Fig. 2)

1. Partial close

• Controller de-energizes primary solenoid (test mode set in

controller) and controller energizes secondary solenoid

• Actuator/valve closes

• Intermediate switch activates

• Secondary solenoid energizes

• Actuator/valve stops in partially closed position.

2. Return to full open

• Controller energizes primary solenoid

• Actuator/valve opens

• Open switch activates

• Controller de-energizes secondary solenoid (test mode is de-

activated)

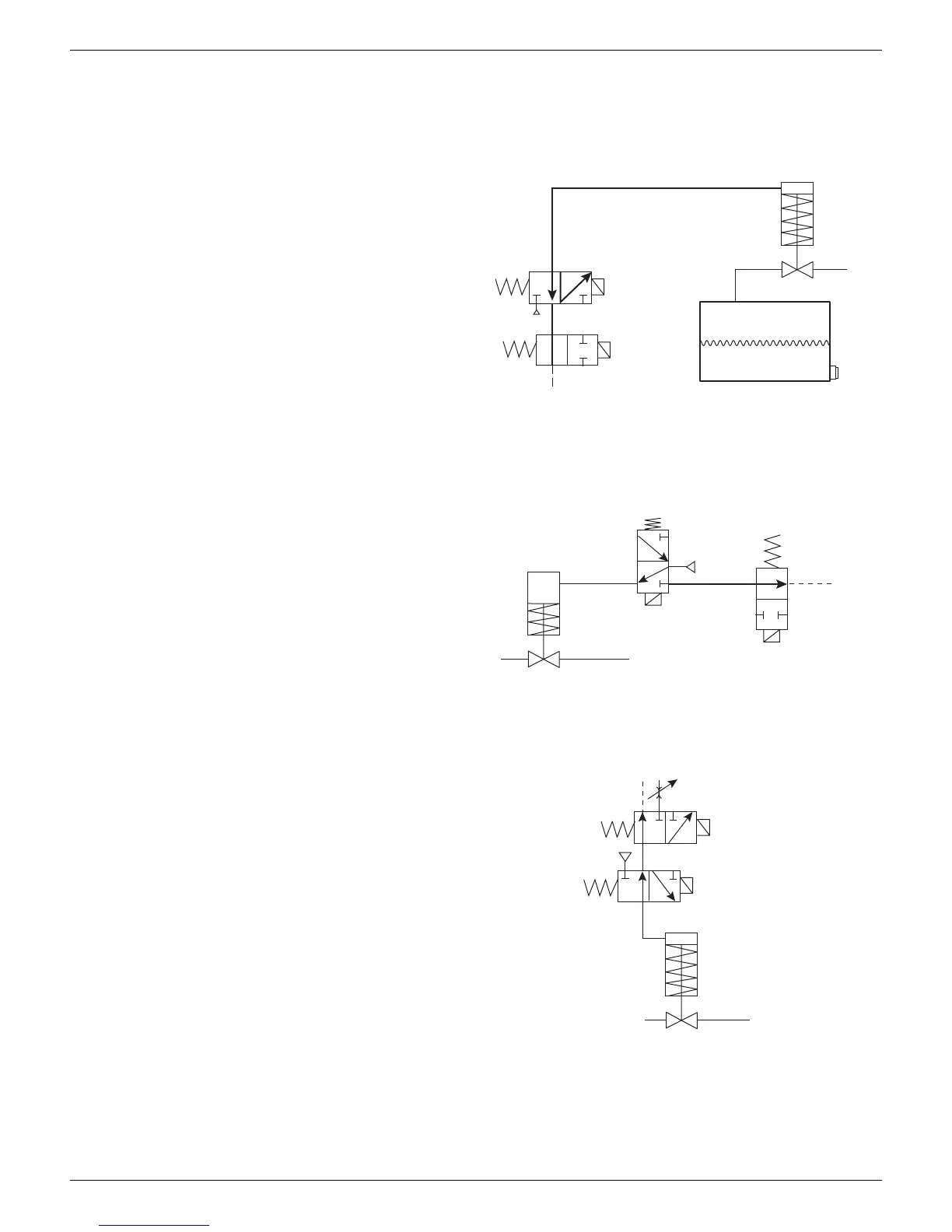

Fill control operation sequence (Fig. 3)

1. Open

• Controller energizes primary solenoid

• Actuator/valve opens

• Open switch activates

2. Rapid to gradual close

• Controller de-energizes primary solenoid and controller

energizes secondary solenoid

• Actuator/valve closes

• ”Intermediate” switch activates

• Secondary solenoid energizes

• Actuator/valve decelerates at preset intermediate position

3. Full close

• Controller de-energizes primary solenoid and controller

energizes secondary solenoid

• Actuator/valve closes

• Intermediate switch activates

• Secondary solenoid energizes

• Actuator/valve decelerates at preset intermediate position

primary

solenoid (NC)

secondary

solenoid (NO)

primary solenoid (NC)

secondary solenoid (NO)

primary

solenoid (NC)

secondary

solenoid (NO)

Fig. 1 ll control

Fig. 2 emergency shutdown (ESD)

Fig. 3 ow dampening

Loading...

Loading...