2

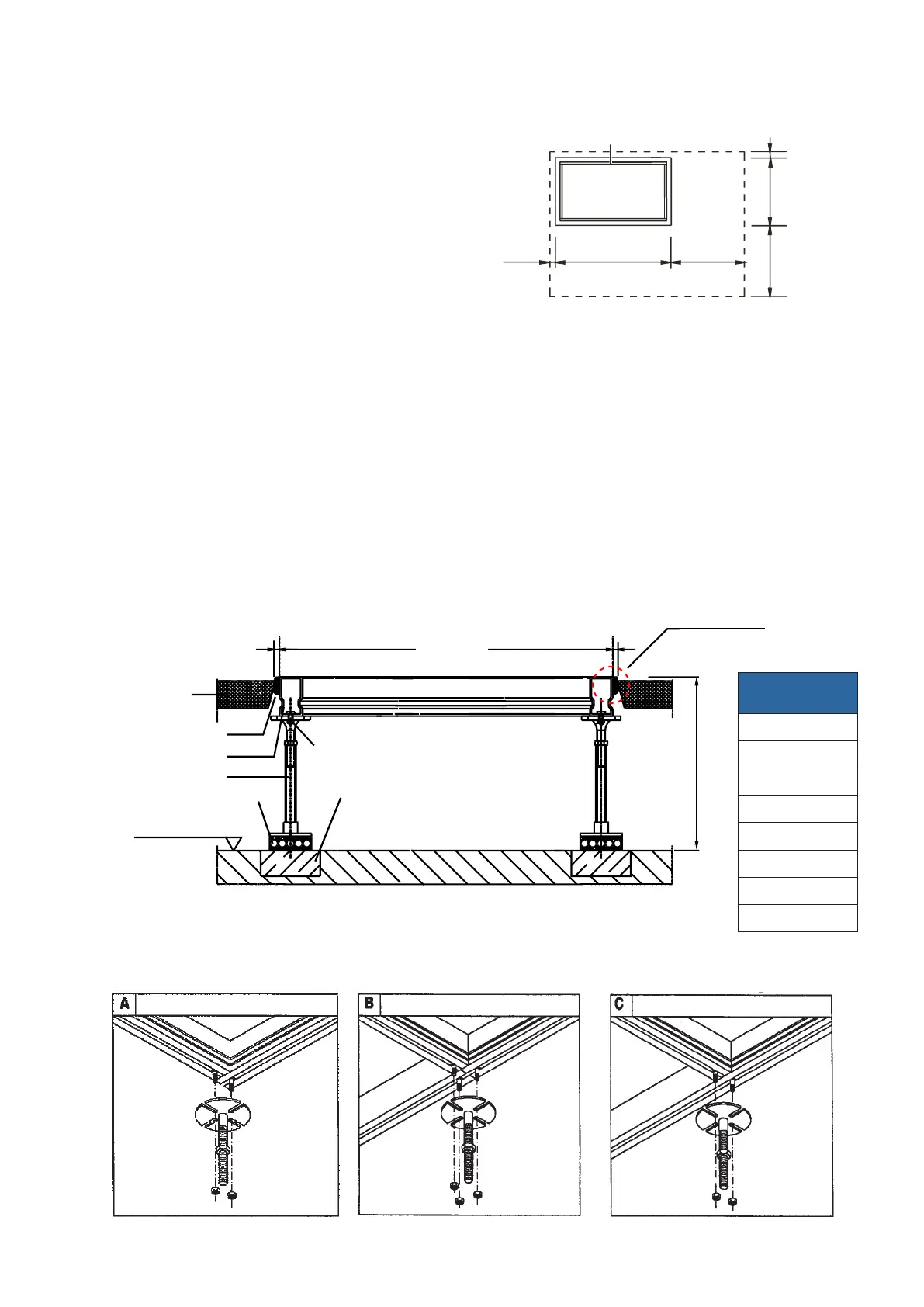

X Z

Y

Z (min. 50)

Z (min. 800)

Z

(min. 50)

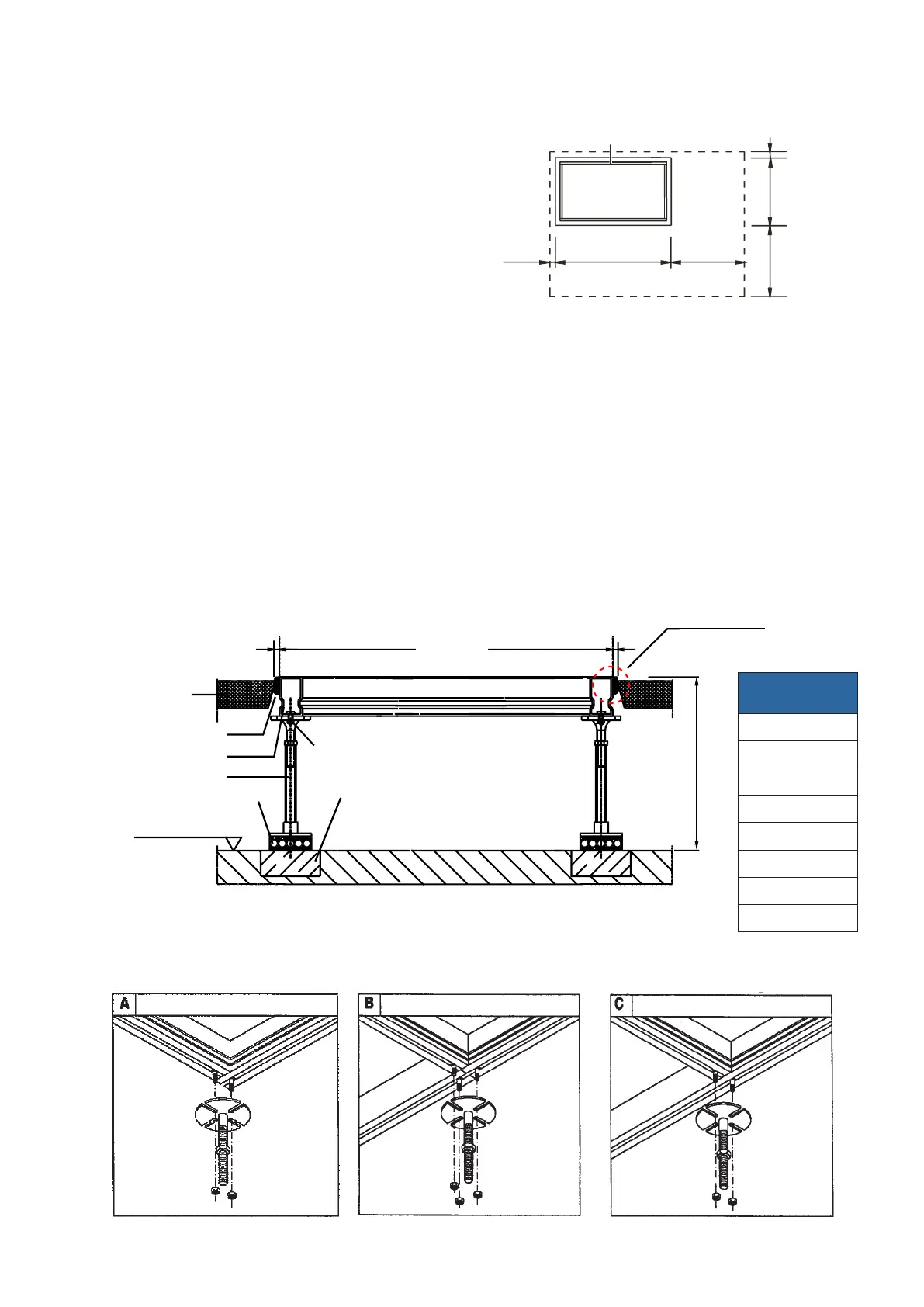

H

min

— H

max

Hmin — Hmax

[mm]

995 — 1045

895 — 945

795 — 845

695 — 745

595 — 645

495 — 545

355 — 405

270 — 320

EN/05.2017 © STULZ GmbH – all rights reserved

raised floor stand

Connecting the bars (View from below)

Angle Connection Butt Joint Cross Connection

Mounting

Raised floor stand

X/Y = Opening in raised floor

Z = Limit of distance

• Aconcretefoundationisrecommendedinthe

area of the raised floor supports.

• Iftheoorstandisplacednearawall,aminimum

distance of 50 mm must be respected. The gap

between wall and floor stand must be closed by

tin stripes.

• Choosethedimensionsoftheopeningsinthe

raised floor (X and Y) 10 mm longer than the

raised floor stand dimensions.

• Closethejointwithacontinuousseal.

• Theraisedoorcutting(notch)shouldat

least be 15° and must not have any contact

totheraisedoorstand,whichcouldresultin

bone-conduction.

• Installtheraisedoorsupportsonvibration

dampening material (Mafund plate) (do not screw

down the supports!).

• PriortoinstallationoftheA/Cunit,installthe

raised floor 7 mm higher than the raised floor

plates,asthemafundplatesarecompressedby

the weight of the A/C unit.

Raised floor connection

fordetails,seenextpage

Hammer head screw M8 30

Recommended concrete

foundations (no floor finish)

Raised floor

Raised floor stand

Continuous seal

Raised floor support

Mafund plate

Upper edge of

rough floor

Unit width

General design of the raised foor stand

Loading...

Loading...